Reclaimers and reprocessors face a huge challenge sourcing and verifying bales of recycled commodities from sorting facilities, collection centres, and brokers. This challenge will only intensify as demand for recycled content soars from brands and consumers. ESG goals set by FMCG companies, minimum recycled content requirements for packaging, and expanding EPR laws will also increase demand and make it harder and harder to source high-quality post-consumer recycled content.

As demand soars and supply remains limited, reclaimers and reprocessors must find a new way to stay ahead of the game. This is especially important when working with highly recyclable packaging materials like aluminium. Aluminium used beverage cans (UBCs) are one of the most common packaging materials, with over 80 billion aluminium beverage cans produced every year. It will be crucial that aluminium reclaimers/reprocessors and, therefore, packaging manufacturers have access to high-quality feedstock to recycle into new products. One way to ensure this is by incorporating AI and robotics into their operations.

How EverestLabs helps

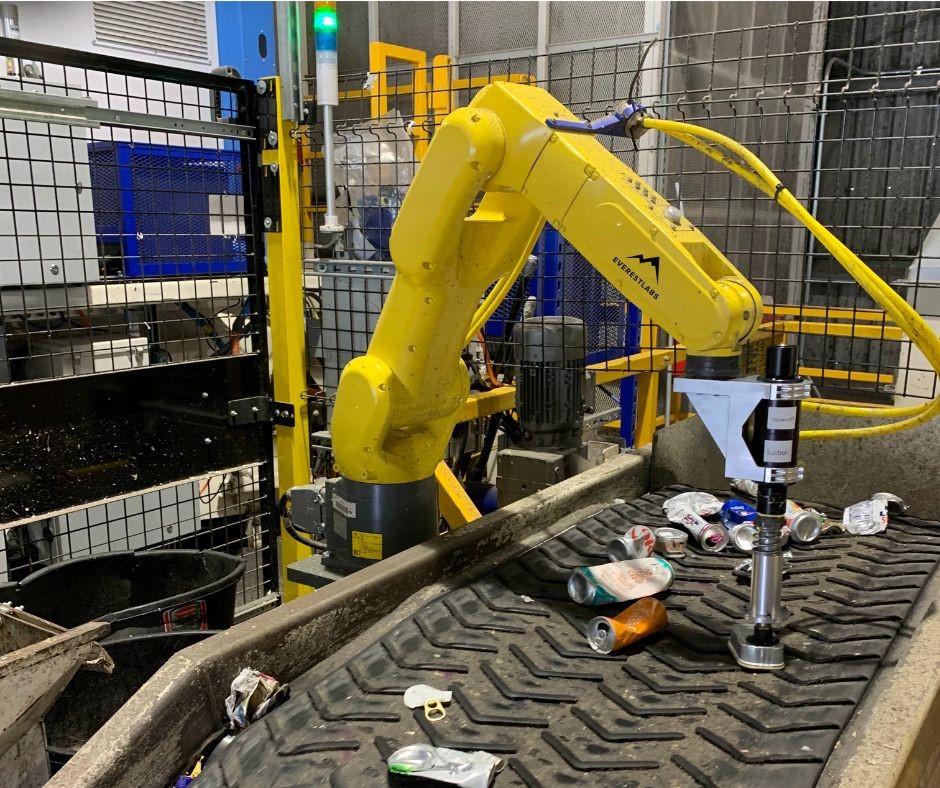

EverestLabs AI and robotics solution, RecycleOS, helps reclaimers trace and verify the supply of recycled feedstock, automate clean-up and sorting to expand their supply base and ensure high yield. Here’s how we do it:

Industry partnerships to increase UBC recovery

Even though they are highly recyclable and valuable, UBCs are often missorted at sorting facilities (MRFs), preventing them from being made back into aluminium cans. Research conducted by the Can Manufacturers Institute (CMI), the trade association for producers of metal cans, found that one in four aluminium beverage cans is missorted at a typical MRF. Further, when CMI analysed UBC sortation at five loss points across three diverse MRFs, on average, the UBCs lost at each loss point was up to 7,000,000 UBCs per year, an estimated total loss of 3.5 billion cans in the US per year. The need to capture these valuable recyclables prompted CMI to explore innovative solutions that could be easily retrofitted into existing sorting facilities.

As a result, in September 2023, CMI initiated a groundbreaking project to fund an EverestLabs robot at a California MRF, Caglia Environmental, to capture revenue generated through collected, misorted UBCs. The sale of the UBCs is intended to pay for the lease of the robot. This partnership aligns the incentives of the packaging manufacturer, reclaimer, and MRF.

Brand identification for CPG companies

EverestLabs also partners with consumer-packaged goods (CPG) companies to place RecycleOS in MRFs or reclaimers. RecycleOS can identify and recover brand-specific packaging in MRFs while providing CPGs with vast amounts of data about the recyclability of the packaging, including recycling rates and recovered value. This data can be used to optimize packaging design and assess the effectiveness of recycling programs. Our data can also report on sustainability metrics that inform EPR and ESG initiatives.

A solution for global recycling efforts

Ultimately, in the face of soaring demand for recycled commodities and a scarcity of high-quality post-consumer recycled material, reclaimers and reprocessors face significant challenges. EverestLabs' solution, RecycleOS, leverages AI and robotics to trace contamination from suppliers, automate sorting, and ensure high yield. Partnerships with packaging trade associations and CPG companies can further boost valuable recyclable recovery and inform sustainability initiatives. This holistic approach can align stakeholder interests, providing a feasible solution for global recycling efforts. To learn more visit, our website.

Responses