Aluminium-driven progress: SAG Group revolutionises vehicle lightweighting to reduce emissions

The Salzburger Aluminium Group (SAG Group), a market leader in aluminium-based vehicle components, is making significant strides in advancing lightweight construction. This will help drastically reduce CO₂ emissions across the automotive and heavy vehicle sectors.

From luxury sports cars that race to high speeds within seconds to heavy-duty trucks built with advanced lightweight parts, SAG’s rheocasting technology has become instrumental in manufacturing durable, high-performance components.

SAG’s lightweight designs for heavy goods vehicles use Fronius’s patented Cold Metal Transfer and WireSense technologies to ensure strength and resilience in even the most demanding conditions.

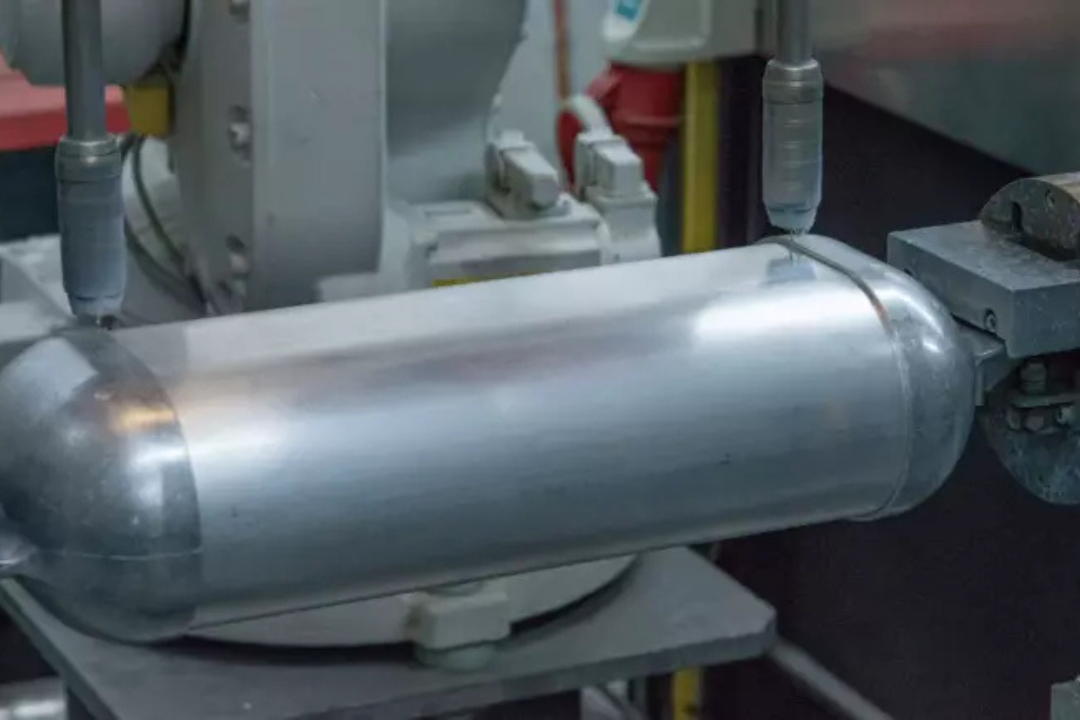

As a global leader in aluminium tank manufacturing for heavy trucks, SAG serves a roster of top-tier OEMs worldwide. Its product offerings span beyond fuel tanks, including lightweight components for railcars, air reservoirs, pressure tanks, and speciality parts for automotive, rail, and commercial vehicles. The company’s rheocasting technology—developed and refined over years of dedicated research—sets it apart by producing exceptionally strong, weldable aluminium components with reduced gas inclusions and shrinkage compared to traditional casting.

Unlike conventional methods that use fully liquid aluminium, Rheocasting processes the metal in a semi-solid state, producing parts with minimal turbulence and low porosity. This results in a high-quality, structurally sound product. SAG’s continuous innovation in this field has positioned it as a trusted name for durable, eco-friendly solutions across the automotive, commercial vehicle, aerospace, and railway industries.

Headquartered in Austria, SAG Group is committed to sustainability and reducing environmental impact through lightweight design. It delivers durable aluminium components that play a vital role in meeting global efficiency and emissions goals.

Salzburger Aluminium Group (SAG) operates globally, with production facilities and subsidiaries throughout Europe, North America, and Asia, enabling it to serve diverse markets and customers worldwide. Known for its commitment to innovation and precision engineering, SAG employs advanced manufacturing techniques to ensure exceptional-quality products. Driven by sustainable practices and energy-efficient solutions, SAG has established itself as a trusted partner in high-performance aluminium applications.

Top Image Credit: SAG Group website

Mid-Image Credit: Fronious

This news is also available on our App 'AlCircle News' Android | iOS