Presently, around the world, the primary technique of processing aluminium scrap is remelting in units of various types and then molten metal is usually cast into ingots. However, in some cases, the melt is granulated or gas atomized to produce powder of recycled aluminium. The remelting-casting technologies are very power consuming.

The newly industrialized country, Indonesia imported 472,683 tonnes of aluminium scrap during 2019-21, which incurred foreign revenue outflow of $600.08 million for the import.

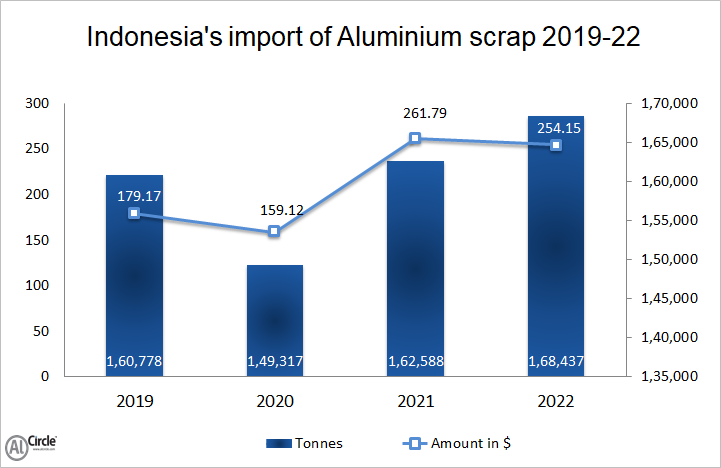

Indonesia, the world’s largest island nation in 2019 imported 160,778 tonnes of aluminium scrap, counting expenditure of $179.17 million, whereas, in 2020, the aluminium scraps import denoted downfall by 7.12%, as the import volume plunged to 149,317 tonnes due to demand and supply constraints rooted to Covid pandemic.

In 2021, the aluminium scrap import was registered at 162,588 tonnes, signified a surge of 8.88% and the expenditure scaled to $261.79 million.

The Indonesian import of aluminium scrap for 2022 is analysed with further growth of 3.59%, as the import volume is estimated to score at 168,437 tonnes, while the expenditure is anticipated to drop at $254.15 million.

The major trading destinations for Indonesia’s export of aluminium scrap are Australia, Germany, Greece, Italy, Japan, New Zealand, Singapore, South Korea, Spain, Taiwan, UAE, UK, USA, etc.

Responses