The USA based Ampal, Inc., a fully-owned subsidiary of U.S. Metal Powders, Inc. and Lehigh University’s Loewy Institute in Pennsylvania, USA, has accomplished the Phase 1 Ben Franklin project on the ‘Optimization of Aluminum Alloy AA6061 powder for Selective Laser Melting Process’.

U.S. Metal Powders, Inc. has been supplying aluminium alloy powders produced by air and inert gas atomization to the additive manufacturing industry for several years. The demand for aluminium alloys has been on the rise and AA6061 (Al-Mg-Si) is one of the most sought after alloy systems in the AM industry, with applications in several industries including the automotive and aerospace sectors.

However, the production of sound parts using AA6061 alloy powder in Selective Laser Melting has been challenging due to the powder’s low flowability and high thermal conductivity.

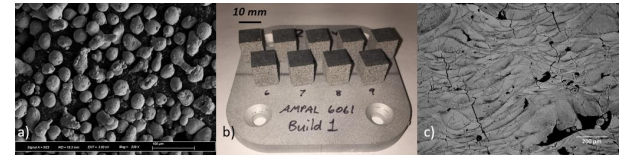

As part of the project, AA6061 inert gas atomized aluminium powder grades were used to print 10 mm x 10 mm x 10 mm solid cube samples using lasers ranging from 200 to 400 Watts. The parts were printed in a Renishaw AM400 unit with a reduced build volume (RBV) unit installed; this deposits powder using a mechanical feed piston system.

Multiple sets of sample parts were printed using Renishaw AM400 with variations in laser power, point distance, and exposure time. The density of each sample was determined using the Archimedes method and light optical microscopy. The metallographic analysis determined optimum build parameters and characterised the meltpool boundaries (MPB) and porosity formed in the PBF-LB process.

Scanning electron microscopy (SEM) revealed a fine microstructure and precipitate formation through natural ageing. Microhardness tests showed promising results comparable to previous literature, leading to high mechanical properties.

AA6061 parts were printed to near-net density by the SLM process at optimum conditions. The optimized process parameters yielded around 98% density for the alloy, with porosities reduced to the minimum by modifying processing parameters.

The Phase 2 project will target the optimization of heat-treated properties, further density improvement, and crack reduction to achieve a commercially viable PBF-LB process to make parts using optimized AA6061 alloy powder and processing parameters.

U.S. Metal Powders, Inc. is the largest aluminium powder producer in North America and global producer of aluminium and aluminium alloy powders, offering a full-range of coarse to fine aluminium powders from its manufacturing facilities Ampal, Inc., USA and Poudres Hermillon SARL, France.

Ben Franklin Technology Partners is an initiative of the Pennsylvania Department of Community and Economic Development and is funded by the Ben Franklin Technology Development Authority.

Responses