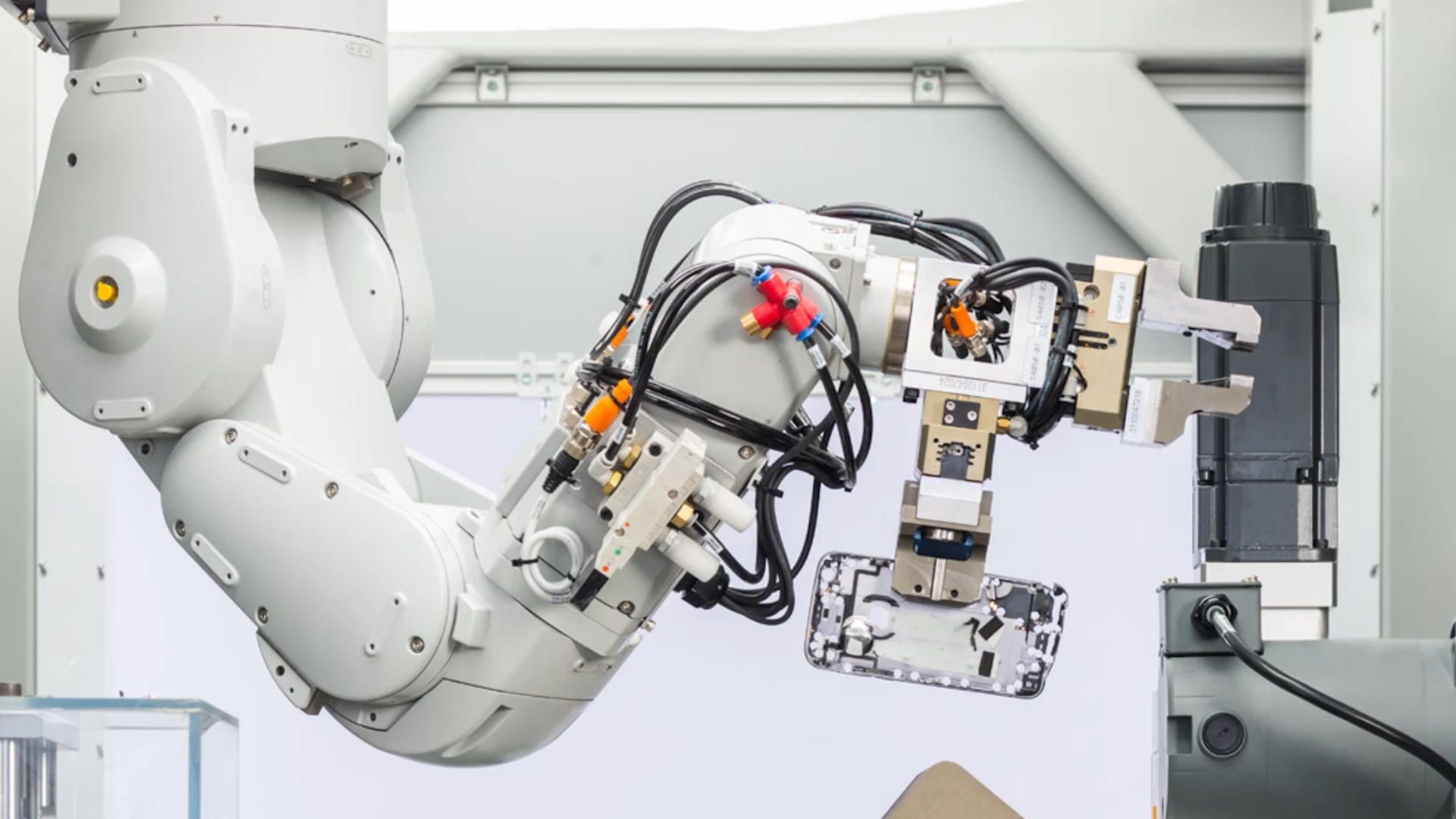

Apple Inc. said on Thursday, April 18, that it would expand its global recycling programmes and introduced "Daisy", its recycling robot that is capable of disassembling 200 iPhones per hour. Apple also announced that it will open a "Material Recovery" lab in Austin, Texas to investigate new techniques using robotics and machine learning to recycle iPhones. The lab will use robots to rip apart iPhones and recover recyclable materials like aluminium, cobalt and copper. The 9,000-square-foot lab is built at the same Austin facility.

The Apple-built Daisy robot is a successor to Liam, another recycling robot made by Apple in 2016. Daisy was created with some of Liam’s old parts, making it a recycled robot that helps recycle iPhones.

Lisa Jackson, Apple's vice president of environment, policy and social Initiatives, told Reuters the research will inform how Apple designs its products.

"I absolutely think that the learnings we make there will be for all of Apple, and hopefully for all of our sector, and of course will influence designers and engineers as we go forward," Jackson said in an interview.

Apple has a long term vision to manufacture all its products from recycled or renewable materials. Apple has not set a date for reaching the goal yet. The lab is however, a part of Apple's broader goal of switching to recycled materials entirely.

In the past, Apple Inc. has come up with a MacBook Air featuring aluminium extracted from melted down iPhones and traded in to Apple.

It is reported that the thin-and-light product designs of Apple prevent proper dismantling and recycling. However, Apple sticks to their commitment to durability and use of minimum materials. Apple also said Thursday that materials recovered by the Daisy robot are making their way into new products.

Responses