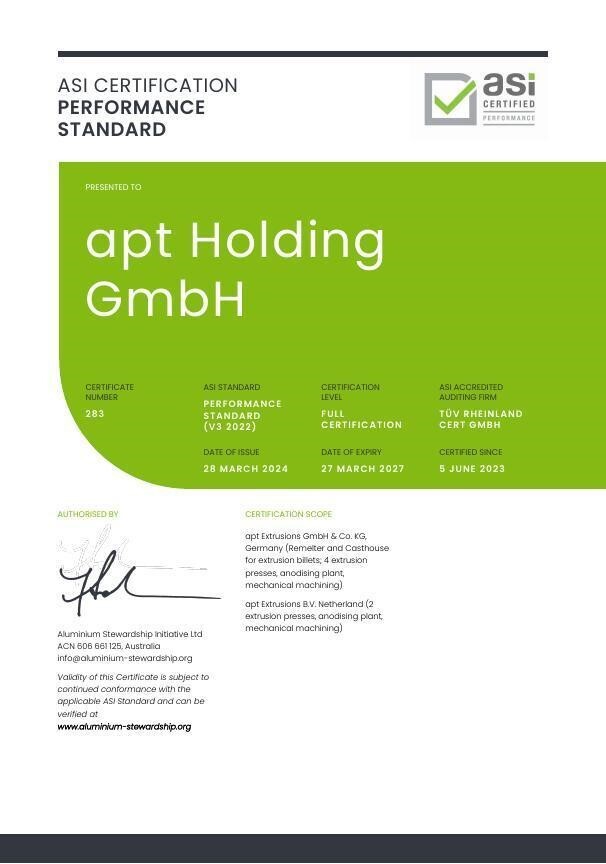

A German aluminium extrusion company apt Holding GmbH has reportedly achieved the ASI Performance Standard V3 (2022) Certification for two of its European facilities - apt Extrusions GmbH & Co. KG facility in Germany and apt Holding GmbH’s apt Extrusions B.V. facility in the Netherlands.

The facility in Germany has remelting and casthouse operations for extrusion billets, four extrusion presses, an anodising plant, and mechanical machining capabilities. The Netherlands facility includes two extrusion presses, an anodising plant, and mechanical machining operations.

apt Holding GmbH is specialised in producing extruded profiles destined for the construction, transportation, automotive, and industrial sectors. Its current production capacities include 80,000 tonnes per year for extrusion presses, 7 million square metres per year for surface finishing, and 15,000 tonnes per year for mechanical processing.

The company received the certification after undergoing an independent, third-party audit by TÜV Rheinland Cert GmbH.

On receiving the certification, Michael Zint, CEO of apt Group, said: “For us, ASI Certification is confirmation that our initiatives to act in an ESG-compliant manner have been successful. Society will only accept energy-intensive production if companies make it clear that they are doing business sustainably on their own accord.”

Fiona Solomon, Chief Executive Officer of the Aluminium Stewardship Initiative, said: “We congratulate apt Holding GmbH on achieving Performance Standard Certification V3 (2022). As a producer of extruded aluminium profiles for a wide range of industries benefiting from the lightweighting, and corrosion resistance properties of aluminium, apt Holding’s Certification highlights the importance of sustainable manufacturing processes and demonstrates their commitment to fostering improved ESG outcomes.”

Responses