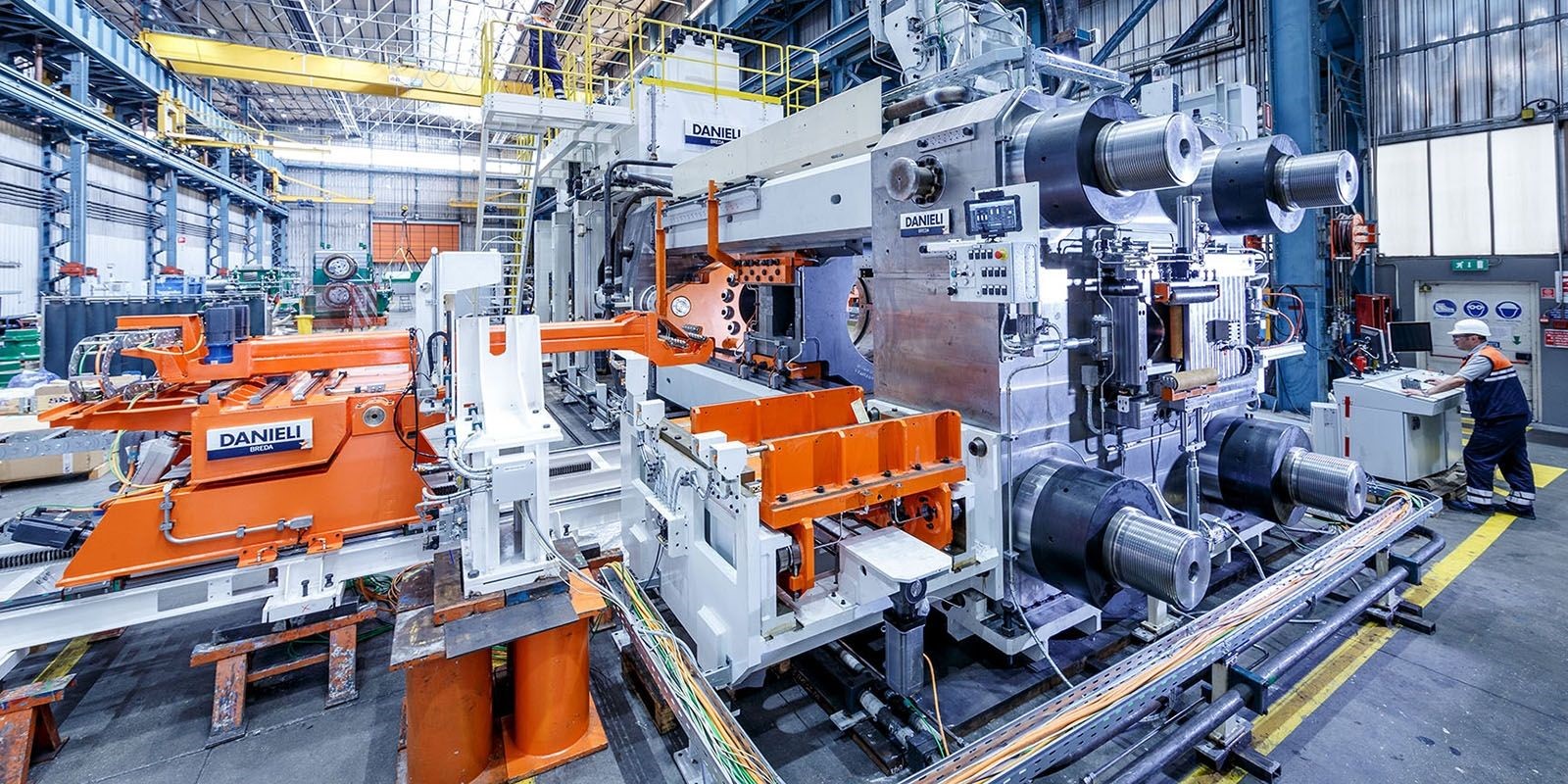

Cansan Aluminium, based in Bursa, will receive a new, 40-MN, 10-in. front-loading extrusion press from Danieli Breda. The new press will allow the company to extrude more hard alloys, allowing it to broaden its automotive profile offerings.

The commissioning of the press is scheduled for 2022.

{alcircleadd}

Turkish company Cansan Aluminum manufactures extruded products for different industries, like automotive, furniture, industry and solar power.

The new press has the latest technological innovations introduced by Danieli, which includes the patented energy-saving system “ESED 4.0,” which enables an average energy savings of 25-30% and fully- electric billet loader and die-change station, eliminating extra hydraulic systems.

The new press features press control system implementing isothermal extrusion, to maintain a constant billet temperature through the die.

Danieli Breda also will ensure that the customer will reach its targets in terms of plant performance and time schedule, by acting as a project director and coordinating the activities of sub-suppliers.

Responses