CEFLEX is the acronym for "Circular Economy for Flexible Packaging", and in 2020, it launched the 'Designing for a Circular Economy' (D4ACE) guidelines for the European packaging sector. CEFLEX and Recyda, two experts in recyclability, have now collaborated to offer a new service called 'Design Check'. This service is available to anyone who wants to assess their packaging design journey quickly and effectively.

The 'Design Check' tool was developed in response to feedback from users of the guidelines who requested a way to verify if a packaging design or specification adheres to the guidelines when assessing their packaging portfolios and developing new products with partners, suppliers, and customers. The service will be launched publicly on September 19, 2023, and an information webinar will be held on the same day. Registration for the webinar is available through the provided link.

CEFLEX design lead Liz Morrish specified the tool's functionality: "The tool can be used either to assess an existing package, facilitate the R&D and design process, engage with other parts of the value chain, or prepare for recyclability testing."

An expert CEFLEX stake-holding team has tested and deployed the tool, inserting confidentiality and protective barriers, making it safe for mass usage. Many of CEFLEX's stakeholders have already utilised this module.

"Assessment covers all parts of the guidelines, including their sortability and recyclability principles. It indicates if a specification or design is compatible, has limited compatibility or is not compatible in terms of the D4ACE categories. Users are also able to undertake assessments for multiple specifications or designs," Liz added.

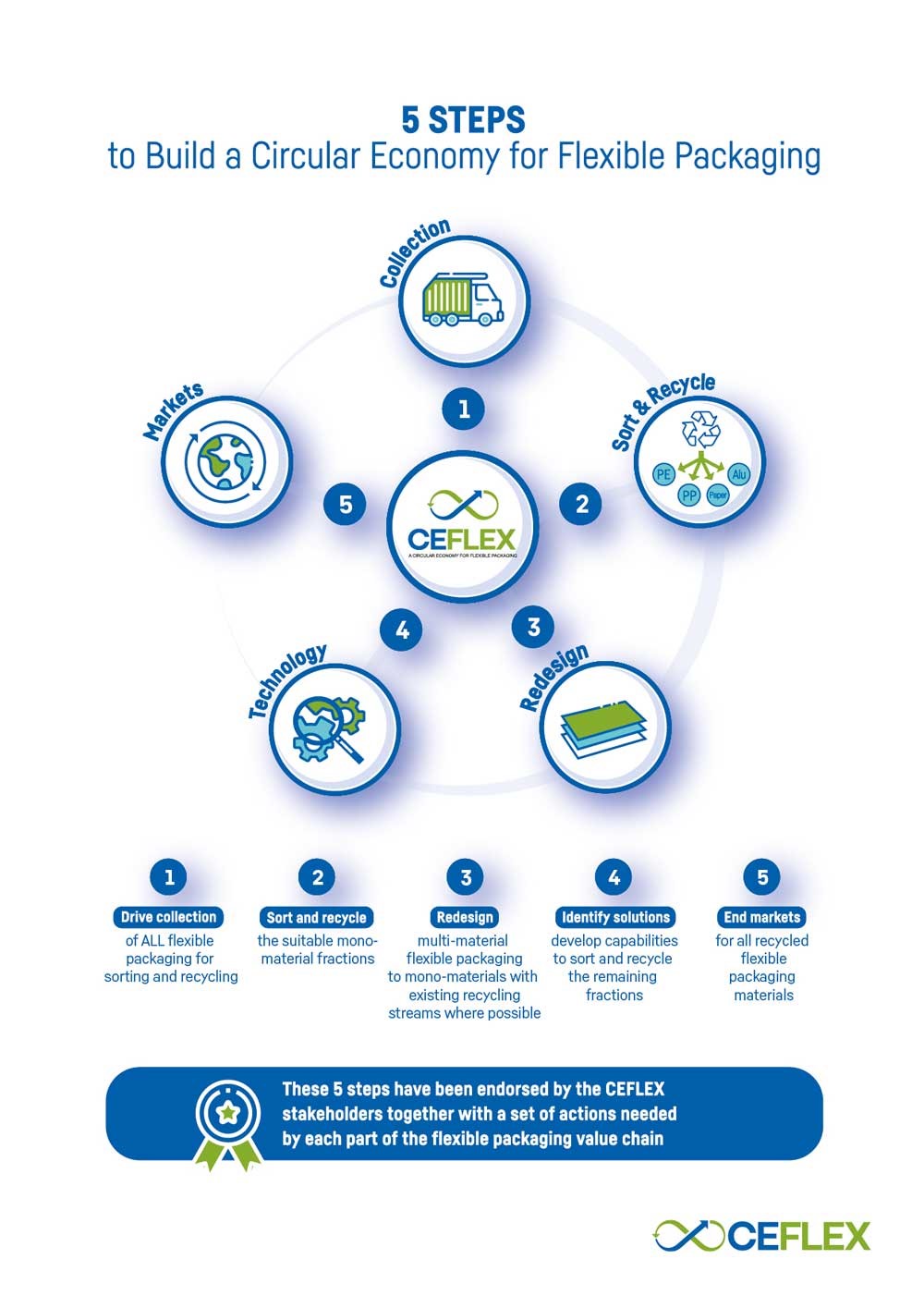

The' Design Check' tool is a valuable resource for designers, packaging technologists, customers and suppliers of flexible packaging. It enables collaboration and innovation throughout the design process, with the aim of ensuring that all flexible packaging is optimised for collection, sorting, and recycling. The ultimate objective is to produce higher-quality recycled materials that can be used again in the circular economy.

Aluminium foil is heavily used in the packaging industry but not just as a mono-material. When aluminium foils over-lap polyethene and other difficult-to-recycle materials, proper sorting and collection becomes immensely important because simple recycling isn't possible in those cases.

Currently, the tool depends on the prevailing CEFLEX D4ACE guidelines, which include mono-material PE and PP structures, but soon, it will soon be revised to cover the aluminium packaging industry. Aluminium is a 100% recyclable material that can induce a circular economy with a closed material loop. Therefore, with the growing demand for aluminium packaging solutions, CEFLEX must incorporate metal packaging protocols.

CEFLEX project coordinator Graham Houlder explained: "The tool could also play a key role in the implementation of an expected EU Packaging and Packaging Waste Regulation (PPWR) conformity assessment procedure. This will require producers and importers of packaged goods to gather relevant technical information and declare that the packaging they place on the market meets legal design requirements."

The CEFLEX' Design Check' tool is not a packaging certification or recycling assessment. It aims to facilitate adherence to CEFLEX's Designing for a Circular Economy guidelines. These guidelines aim to make flexible packaging circular by providing clarity, increasing collection and recycling, and producing higher-quality recycled materials. CEFLEX is a collaboration of over 180 European companies working to make all flexible packaging in Europe circular by 2025.

Responses