您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

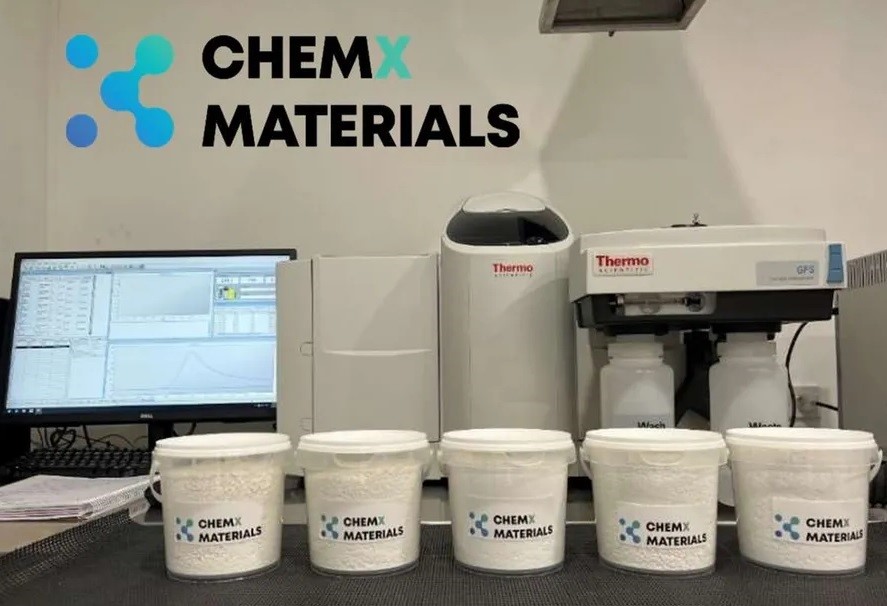

ChemX, an Australia-based high-purity critical materials company, is thrilled to report considerable development in both the high-purity alumina (HPA) and high-purity manganese (HPM) business streams. The Australian-based company has made progress in refining its high-purity alumina (HPA) micro-plant flowsheet in anticipation of scaling up to pilot-plant production. The business claims that investment in high-precision analytical equipment and devoted human resources has improved operational performance for its HPA micro-plant. A first-ever high-purity manganese mineral resource estimate is also on the way.

ChemX Materials has been developing its 100 per cent-owned HiPurA® HPA Pilot Plant, which will be located at its dedicated facility in O'Connor Perth, Western Australia, to deliver the required volumes of HPA for product qualification with Battery Separator manufacturers, consumers of high purity aluminous products, and synthetic sapphire producers. ChemX has found markets for intermediate high-purity aluminous compounds, which provide potential volume increases in addition to the markets for 4N and 5N HPA, as a consequence of marketing operations and industry conversations.

"The Micro-plant has proven extremely effective in delivering the process data required to improve the design and optimise the operation of the Pilot-plant ahead of time. This has resulted in a significant reduction in capital costs and reagent requirements. Importantly, the resized pilot plant will still meet expected customer demand in producing a sufficient product to complete the qualification with battery separator makers, synthetic sapphire growers and other burgeoning markets," said ChemX Materials chief executive officer Peter Lee.

The firm has recently uncovered additional paths for intermediate high-purity alumina (HPA) products. This development has been facilitated by investments in advanced analytical equipment and the allocation of specialised personnel, leading to enhanced operational efficiency at the HPA micro-plant. The company will incorporate the improvements directly into the HPA pilot-plant flowsheet design, thus enhancing its ability to scale up the metallurgical processes more assuredly.

High-purity alumina (HPA) is commercially available in powder and pellets. Its quality is assessed based on its level of purity, with a product that is 99.99% pure being classified as "4N," denoting the presence of four nines. Similarly, 99.999% pure alumina is referred to as "5N" HPA, indicating the presence of five nines.

ChemX has reported that continuous marketing efforts and industry dialogues have resulted in the discovery of new intermediate product paths that provide opportunities for increased production volumes. These pathways are in addition to the existing markets for 4N and 5N high-purity alumina (HPA). The company's objective is to attain the production and distribution of 4N and perhaps 5N high-purity alumina (HPA) goods for various industries, such as electric car battery separators, synthetic sapphire markets, LEDs, semiconductors, and optical lenses.

The incorporation of improvements to the flowsheet and the management's exploration of other product paths will delay several weeks in building the pilot plant. However, this effort is expected to enable the production of alternative intermediate products in a single plant. ChemX has outlined its plans, including adapting the micro-plant to use feedstock from the pilot plant. This strategic move aligns with the company's objective of advancing towards the manufacturing of high-quality goods, including 5N HPA.

HPA is becoming more popular in the lithium-ion battery industry, where it is employed as a coating on the separator sheets between the cathode and anode. It is also used to make synthetic sapphire, a transparent, high-strength material used in various applications such as LED lights, semiconductor wafers, and quality watch faces.

Responses