Closed loop recycling success: Capral and Rio Tinto partner on sustainable aluminium initiative

Australia's largest aluminium extruder, Capral, has successfully completed a trial using recycled-content billets supplied by Rio Tinto at Boyne Smelters Limited (BSL) in a significant stride towards sustainable manufacturing. This innovative process involved remelting 50 to 100 tonnes of post-production aluminium scrap sourced from Capral's Bremer Park extrusion plant in Southeast Queensland.

As a result, billets containing at least 20 per cent recycled content were produced, signalling a sustainable step forward in local aluminium manufacturing.

The trial highlights a closed-loop system that embodies waste minimisation and a marked reduction in the carbon footprint associated with aluminium extrusions. This initiative aligns seamlessly with the Australian Government's Future Made in Australia policy, reinforcing the country's commitment to sustainable industrial practices.

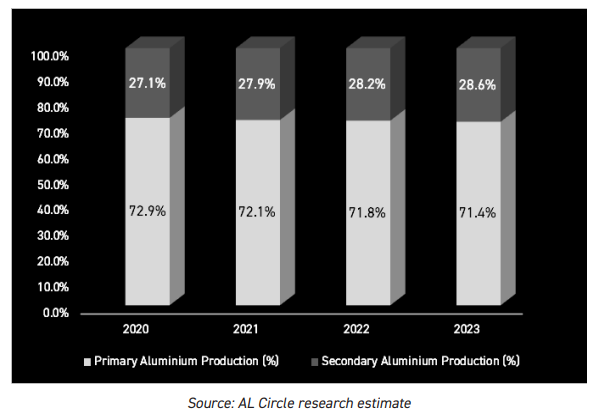

World Aluminium usage: Primary to recycled aluminium ratio, 2020 – 2023 (% ratio)

Notably, the entire value chain has remained within Australia. From the raw materials of bauxite and alumina to primary aluminium production, through Capral's extrusion process, and finally to Rio Tinto's innovative remelting of scrap – every step was carried out domestically. This achievement showcases Capral's dedication to environmental stewardship and marks a significant step forward for the Australian aluminium industry.

Capral is now considering integrating this sustainable billet into its broader product offerings, a move that could reshape local aluminium production standards and promote eco-friendly practices within the industry.

This successful trial at BSL demonstrates the potential for Australia to lead with closed-loop aluminium solutions, setting an example for sustainable manufacturing and contributing to a greener future.

Luke Hawkins, Capral Divisional General Manager of Industrial Solutions and Supply, said, "Whilst Capral recycles the vast majority of our scrap, it must be sent offshore for processing and typically ends up in different types of products than what we would normally produce. We are excited to be working with Rio Tinto, our main domestic supplier, on this project; hopefully, in the not-too-distant future, we can recycle all of our scrap locally and use it to support circularity within the Australian aluminium industry."

By supplying post-production scrap to Rio Tinto, Capral effectively closes the loop, keeping valuable materials in circulation within Australia and converting them into practical products. This partnership offers Capral a strategic solution for efficiently managing its waste stream while bolstering its sustainability profile.

Luke added, "We are driven by the industry to incorporate recycled content into our supply chain. We've worked hard to introduce LocAl and LocAl Super Green, our lower carbon aluminium offer, and the addition of this aluminium material with 20 per cent recycled content is another important step in our evolving procurement strategy towards delivering more sustainable aluminium to Australian manufacturers."

Blending post-production recycled content with virgin material produces billets that meet the high-quality standards demanded by industries such as construction and transportation. This method underscores the practicality of closed-loop recycling, redefining conventional views on production efficiency and resource utilisation.

Capral, the only Aluminium Stewardship Initiative (ASI) certified extruder in Australasia, is responsible for sourcing and managing aluminium throughout the value chain.

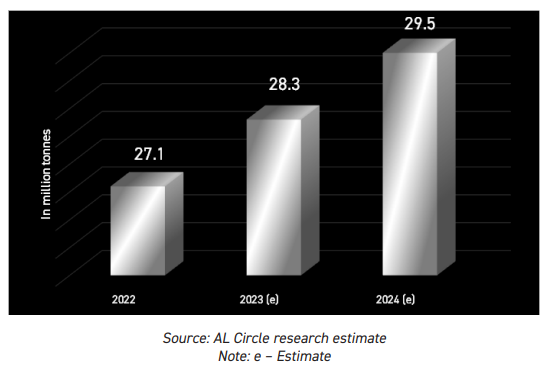

World recycled aluminium usage, 2022 - 2024 (million tonnes)

Recycled aluminium usage across the world increased from 27.1 million tonnes in 2022 to 28.3 million tonnes in 2023. Usage is expected to increase to more than 29 million tonnes in 2024.

Many of the primary aluminium producers have invested in setting up recycling facilities and are investing further in advancing their capacities. Some large players, such as Alcoa (Sustana), Hydro (Circal), Novelis (AL:sust™’), Constellium (CirConAl), etc., have closed-loop scrap collection arrangements with their customers. For an in-depth understanding of aluminium recycling consumption patterns across different regions, AL Circle's comprehensive industry report, "World Recycled Aluminium Market Analysis – Industry Forecast to 2030," provides critical insights and projections. This report delves into the global aluminium recycling sector, offering detailed analysis and forecasts that highlight trends and future growth trajectories.

Images credit: Capral Aluminium Press Release

This news is also available on our App 'AlCircle News' Android | iOS