Constellium and Renault Group complete “ISA3” R&D project for a sustainable, lightweight automotive design solution

On Thursday, December 12, Constellium SE, a Paris-based rolled and extruded aluminium products company, announced the successful completion of the "ISA3" R&D project, which brings a lightweight solution to automotive design.

Image Source: LinkedIn

The project started in 2021 with a grant from the France Relance investment program and in partnership with Renault Group, ESI Group, the Institut de Soudure (Welding Institute), and the University of Lorraine. Upon completion, Constellium has set a benchmark in designing automotive aluminium components that are lightweight, cost-efficient, and recyclable.

The significant development in this project is a lightweight aluminium door, using Constellium's uni-alloy 6xxx rolled and extrusion-based solutions. Owing to the design and use of lightweight metal, the door weighs 14 per cent less than the current aluminium door used in compact battery electric vehicles. Besides reducing weight, the usage of a single alloy series for the door also advocates closed-loop recycling to reduce carbon footprint.

The next-gen door can go through closed-loop recycling throughout its lifecycle, delivering a 33 per cent reduction in Global Warming Potential (GWP), underscoring the project's focus on sustainability.

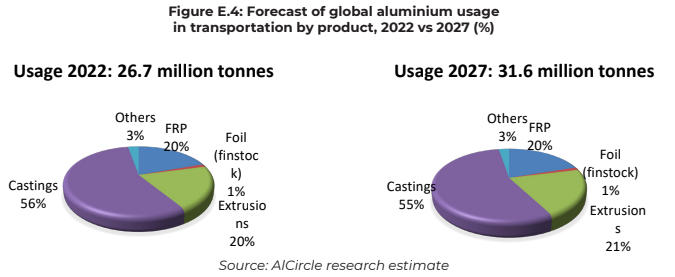

Owing to all these factors, aluminium becoming the most preferred metal in transportation and its usage is growing globally each year. According to AL Circle’s report “Future of Aluminium in Transportation Sector”, the total aluminium usage in the particular sector will exceed 30 million tonnes from 26.7 million tonnes in 2022. Of all the aluminium products used in vehicles, the usage of aluminium extrusion will lead, growing to 21 per cent by 2027 from 20 per cent in 2022.

Ludovic Piquier, Senior Vice President of Manufacturing Excellence and Chief Technical Officer at Constellium, said: "We are proud of the results of Project ISA3, which highlight Constellium's dedication to providing sustainable, high-performance solutions for the automotive market. The innovations achieved through this collaboration demonstrate aluminium's transformative potential to support the decarbonization of the automotive industry, while delivering cost benefits."

Patrice Belliard, Expert in Flat Products at Renault Group, remarked: "Project ISA3 has been instrumental in demonstrating how aluminium solutions can contribute to achieving both weight and cost reductions in automotive manufacturing. This project reinforces our commitment to integrating lightweight, sustainable materials into our vehicle designs."

Mathilde Chabin, Manufacturing Product Director at ESI Group, added: "Leveraging ESI Group's expertise, Project ISA3 relied on advanced pre-certification and validation technologies, enabling the development and manufacturing of aluminium doors without the need for physical prototypes. This approach has accelerated innovation while reducing costs and environmental impact."

This news is also available on our App 'AlCircle News' Android | iOS