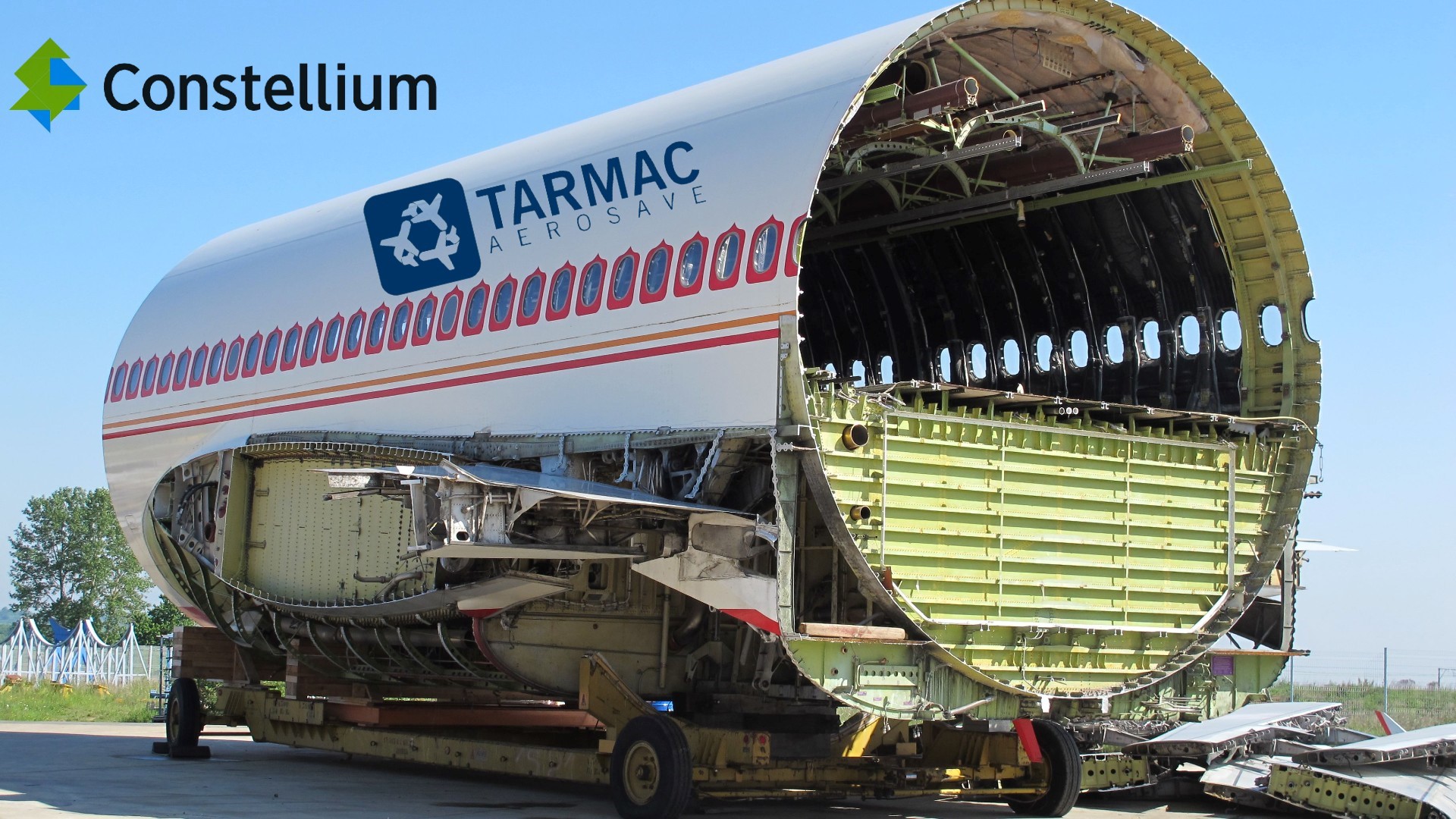

Constellium SE and TARMAC Aerosave are collaborating to discover technologies and processes that will enable the recovery of aluminium from end-of-life aircraft. This innovative approach involves reusing aluminium within the aerospace value chain, thereby keeping its material properties and original performance intact.

This method has proven advantageous since the carbon footprint of aluminium is more feasible in comparison with other elements used in aircraft production. Furthermore, using recycled aluminium adds to this advantage by significantly reducing CO2 emissions. It is noteworthy that recycled aluminium requires just 5% of the energy used for primary metal production, resulting in 95% lower CO2 emissions for the aluminium produced to craft commercial aircraft.

TARMAC Aerosave's expertise will come in handy for dismantling and validating end-of-life aircraft, whereas Constellium's extensive knowledge in metallurgy, aluminium recycling, and alloy design will aid in creating a circular economy. The primary focus of the project is to highlight the full circularity of aluminium in high-quality, precisely engineered aerospace components.

The Facility and EHS Director for TARMAC Aerosave, Sebastien Medan, explained: "Dismantling of the aircraft and reuse of components and materials are already part of our core business. This collaboration with Constellium encourages us to explore the valorisation of the end-of-life airframes even further and to expand our contribution towards the ambitious decarbonisation targets set by the commercial aviation sector."

The President of Constellium's Aerospace & Transportation business unit, Ingrid Joerg, narrated: "Recycling is at the core of Constellium's strategy. Returning aluminium from end-of-life metallic aircraft structures back into our process is critical to achieving full circularity for commercial aviation. Aircraft recycling currently faces many technical challenges, but every effort to decarbonise the aerospace industry is necessary. As a technology and market leader in aluminium solutions, Constellium is committed to playing its part."

Constellium is an internationally acclaimed company that creates aluminium products for aerospace, automotive, and packaging markets.

TARMAC Aerosave is the largest aircraft and engine storage capacity in Europe, with three sites accommodating over 280 aircraft. They offer maintenance, transition, and recycling expertise for various commercial platforms and have a dedicated engine workshop. The company is environmentally conscious, with advanced dismantling and recycling techniques that have earned them ISO certification. They have over 1,470 aircraft accommodated, 1,000 redelivered, and 360 aircraft and 190 engines dismantled. TARMAC Aerosave has solid shareholders, including Airbus, Safran Aircraft Engines, and Suez.

Responses