Post-pandemic, the use of aluminium honeycombs in the railway industry has increased significantly. To win back the passengers' trust, rail sector stakeholders have decided to improve the train's interiors by incorporating an aluminium honeycomb design from Corex Honeycomb.

Due to its strength, sustainability, and lightweight, aluminium honeycomb offers a valuable solution for interior design training. The Corex aluminium honeycomb core is strong, lightweight, resistant to corrosion and 100 per cent recyclable, making it ideal for use in internal train applications like doors, floors, furnishings, galleys, sanitary modules, and partitions.

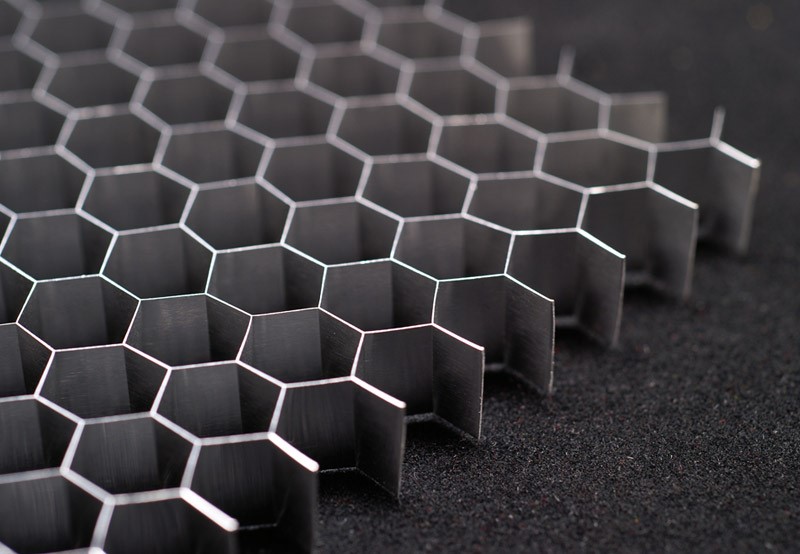

Because the hexagon is one of nature's strongest shapes, the honeycomb cell shape was inspired by the hexagonal shape used to build beehive walls. Due to the geometry of its design, it uses the least amount of material to support the most weight.

For the past 20 years, Corex Honeycomb has been producing high-quality aluminium honeycomb and selling it to businesses worldwide. Lightweight structural material with an excellent strength-to-weight ratio, aluminium honeycomb is helpful for various applications.

The company offers honeycomb in different shapes, including complete blocks or chopped slices, expanded or unexpanded, perforated or unperforated. Corex's honeycomb is highly sought-after and appropriate for usage wherever lightness and strength are required because of its exceptional strength-to-weight ratio.

Around the world, railway shows are held to study and present the most recent applications, research, and advances aimed at improving train travel. One such event is InnoTrans, the European premier international trade fair for transportation technology.

Responses