Cymat Technologies Ltd. publicised the commencement of prototype automotive component production for an electric vehicle manufacturer ("OEM"). After a year of collaboration with the OEM, Cymat has developed an innovative aluminium solution for the underside impact protection of a new electric vehicle's battery enclosure.

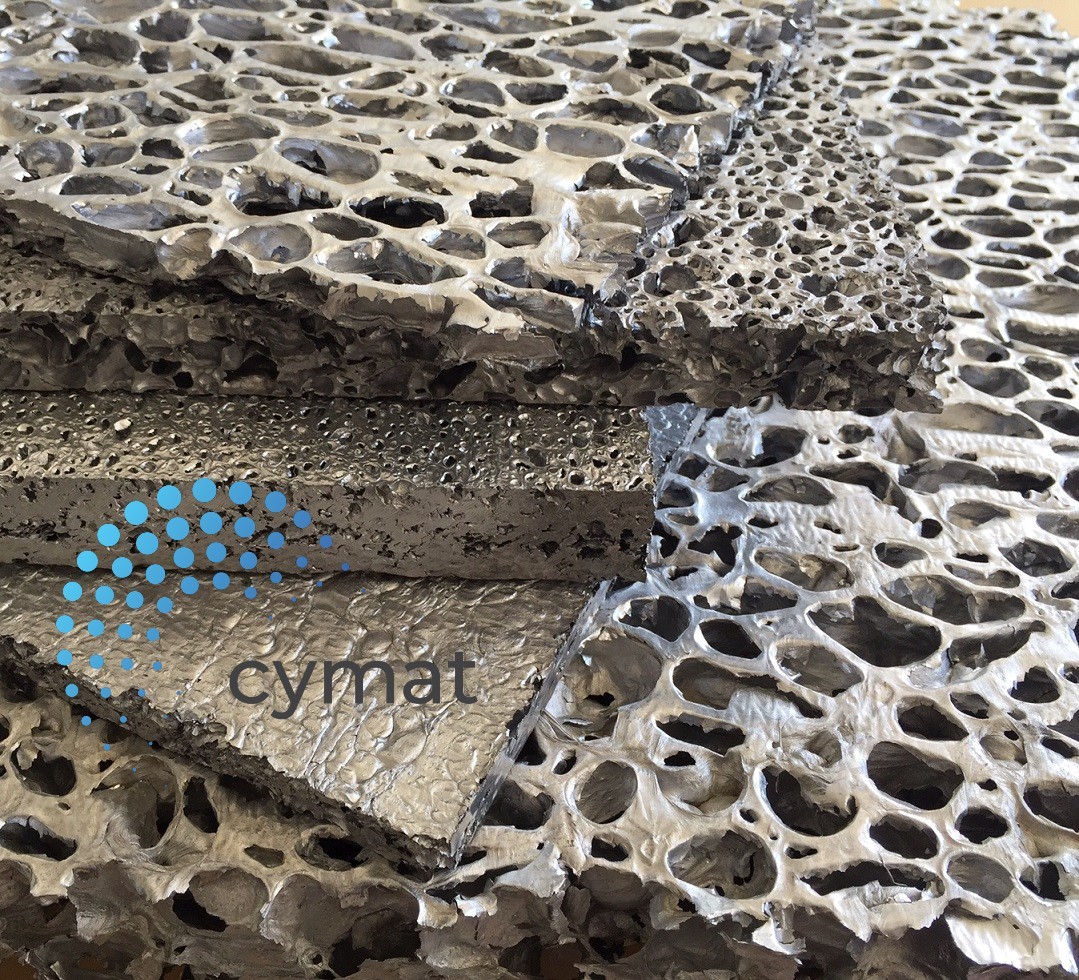

The traditional industry solution has failed to meet the OEM's criteria, leading them to seek Cymat's expertise. Together with Tesseract Structural Innovations, Inc. ("Tesseract"), Cymat has created an advanced aluminium foam sandwich structure featuring an ultra-thin version of high-density SmartMetal™ aluminium foam.

This component is designed to withstand an impact force of 120 joules from an object the size of a trailer hitch ball, equivalent to a collision at 48 miles per hour. Compared to the traditional steel solution, Cymat's design is 40% lighter and more cost-effective, crucial for electric vehicles where weight impacts vehicle range and causes roadway damage.

The aluminium foam structure developed by Cymat offers advanced crash protection, a critical feature for companies focusing on environmental, social, and governance (ESG) goals. Cymat and Tesseract have worked diligently to meet the OEM's stringent impact protection standards by leveraging computer simulations to design the component. The next testing phase involves physical impact testing to validate the simulation results.

Once these tests are complete, Cymat intends to engage in discussions regarding the manufacture of the component for a new electric vehicle, slated to debut in late 2024 or early 2025. Cymat has exclusive rights to this design concept, which can be applied to technically all other electric vehicle battery enclosures. The company plans to use the results of the tests, including high-speed video footage of the component's performance, to showcase its design to other electric vehicle OEMs and parts manufacturers.

Michael Liik, Cymat's CEO, mentioned in a statement: "This is the first time that Cymat has advanced to the prototyping and physical crash-testing stage with an automotive OEM."

"I am particularly excited about the ability to market this innovative design concept to other automotive companies and parts suppliers who are all faced with the same battery enclosure challenges. This development further validates our strategy of focusing on developing technology to enhance the performance of battery enclosures for electric vehicles, an area still very much in its infancy," Liik insisted.

Cymat is closely collaborating with various automotive OEMs and parts manufacturers to develop additional components, as previously mentioned in press releases from July 5, 2022, and December 13, 2023. We will provide updates on these development programs and other automotive initiatives shortly.

Responses