On July 16, 2024, Emirates Global Aluminium (EGA) marked a significant milestone by completing the design phase for its cutting-edge smelting technology, EX. This innovation represents a leap forward from EGA's DX+ Ultra technology, which is known for its efficiency in the global aluminium sector.

The EX-reduction cells, larger than the DX+ Ultra, promise enhanced capabilities with increased amperage and improved current efficiency. This advancement is expected to boost production capacity by up to 22 per cent, underscoring EGA's commitment to pushing the boundaries of aluminium production.

Designed with versatility in mind, EX offers two distinct variants: one prioritising productivity and the other aiming to minimise greenhouse gas emissions. This adaptability reassures stakeholders that the technology can be tailored to meet specific production and sustainability goals.

EGA plans to validate and fine-tune the EX technology through the construction of 10 pilot reduction cells at its Al Taweelah smelter. The goal is to achieve full industrialisation of EX by 2028, solidifying EGA's position at the forefront of sustainable aluminium production.

The DX+ Ultra technology, already renowned for its efficiency, sets a high benchmark in the industry, reflecting EGA's unwavering commitment to innovation and sustainability in global aluminium manufacturing. This commitment instils confidence in EGA's leadership in the industry.

Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium, said, “Technology development has been a foundation of our global competitiveness for decades. EX technology will enable the production of more aluminium with less energy and lower emissions, unlocking opportunities for EGA’s growth and helping us to meet the increasing global demand for the low carbon primary aluminium required to reach net zero by 2050.”

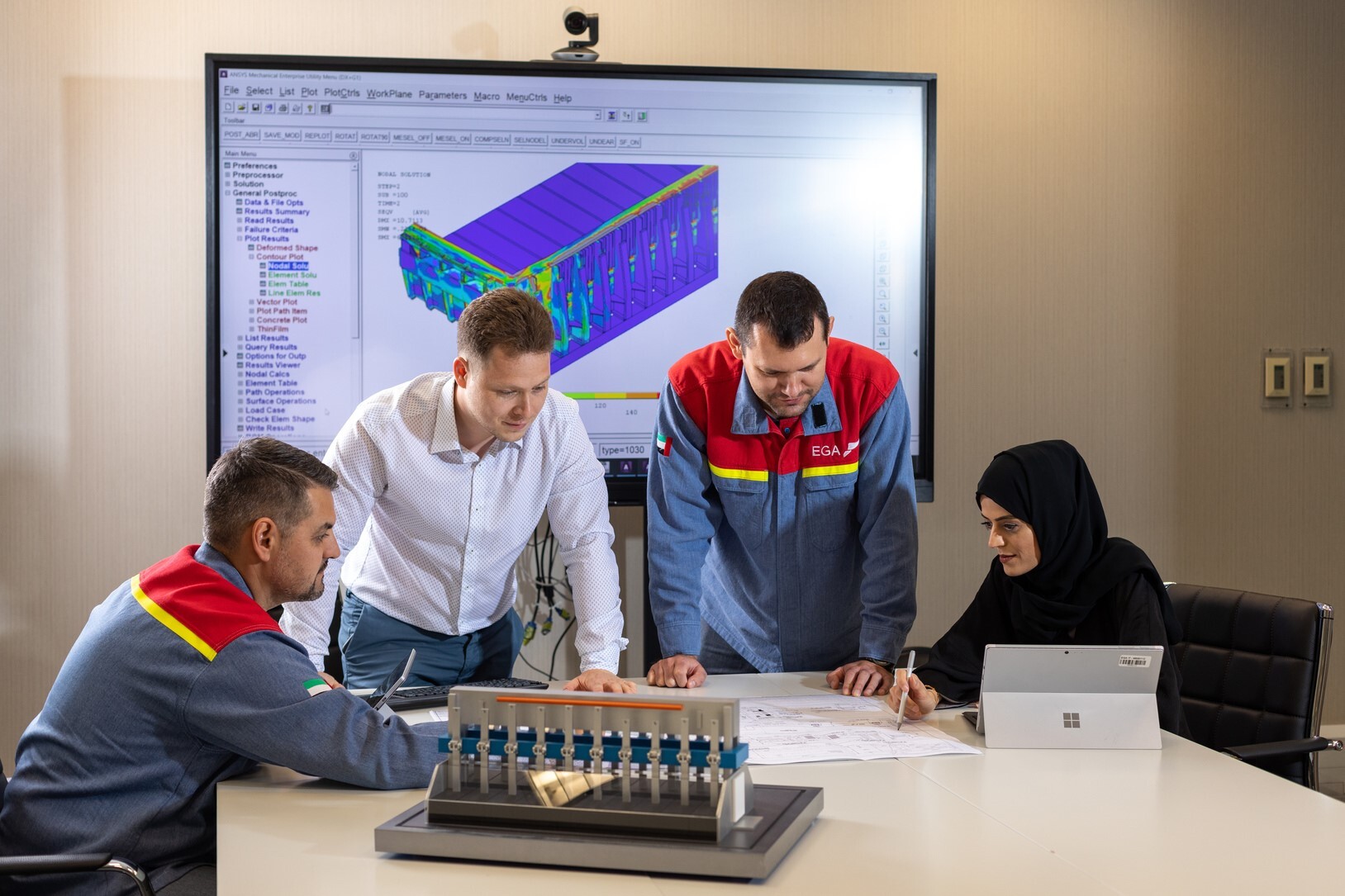

EGA's latest advancements in EX technology promise significant enhancements in pot performance, achieved through upgraded busbars, superstructures, and potshells. These improvements aim to reduce surrounding temperatures, thereby enhancing the working environment. Developed over 18 months by EGA's Technology Development Design team, the pilot reduction cells are scheduled for commissioning in early 2025.

For over three decades, EGA has not only pioneered aluminium smelting technology in the UAE but also significantly impacted the global stage. Since the 1990s, the company has integrated its proprietary technology into every smelter expansion and retrofitted older production lines. In a landmark move for the UAE industry, EGA licensed its core process technology internationally in 2016 to Aluminium Bahrain, enabling its implementation in the Potline 6 expansion project.

Responses