Evonik Industries, a German industrial conglomerate and one of the largest specialized chemical firms in the world had collaborated with VESTARO GmbH consortium to create a new generation of battery packs, the "Pure Performance Battery,” (PBB). Other members who were a part of this creation include Forward Engineering, a composite structures expert, and Minth, a Tier 1 automotive supplier.

Minth joined the collaboration in 2021, bringing with it extensive experience with aluminium solutions, allowing the organisation to address two significant issues that existing battery packs face: the bottom impact use case and vehicle integration.

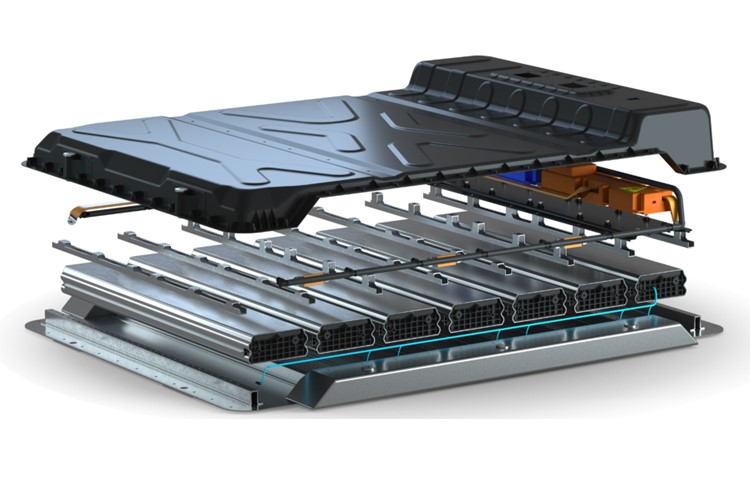

The Pure Performance Battery (PPB) is roughly 2.1m long and 1.58m broad, with maximum heights of 0.15-0.22m, and is reported to be appropriate for a range of vehicle designs. It was designed and verified using Forward Engineering's battery electric vehicles (BEV)-floor structure development tool.

Vestaro, which was founded at the end of 2019 to look into alternative battery solutions, first produced a cost-effective glass fiber-Sheet Molding Compound (SMC) battery pack cover using Evonik's epoxy curing agent Vestalite S. This technology ensured a much lighter, safer and cost-effective solution for traditional battery electric vehicles (BEV). The SMC materials not only reduced the weight of the battery housing by over 10% compared to similar covers produced from more expensive materials, but they also functioned similarly to earlier metal-based enclosures while allowing for more design freedom.

“Our new battery pack is designed for performance and it’s the exceptional properties of our VESTALITE curing agents that give the unique Epoxy-SMC-cover its outstanding performance and safety potential in terms of fire-resistance and crash behaviour. We’ve successfully overcome all concerns regarding the EMI-shielding performance of the GF-composites using Evonik’s broad material toolbox and expertise and we can tailor the PPB’s performance to meet each customer’s individual requirements,” said Sebastian de Nardo, Marketing Director for Adhesives and Composites at Evonik.

The collaboration devised a strategy that fully used the design freedom of the SMC material to achieve severe Original Equipment Manufacturer (OEM) standards in terms of side pole and bottom impact testing without any leakage or failure. The former bottom structure was replaced with a Minth-developed aluminium sandwich plate, which improved bottom impact performance while also making the pack a semi-structural component of the vehicle chassis. The collaboration was also able to eliminate the extra side deformation components with this approach and instead use the available space to add more battery cells.

Furthermore, the area required for module installation might be decreased due to the sandwich floor's increased bottom impact performance. The added room for battery cells resulted in a 10kWh increase in overall capacity, from 65kWh to 75kWh, while maintaining the same battery pack outside dimensions as the consortium's previous iteration.

The battery's semi-integral modular architecture allows for a variety of module counts. It employs a'supercell' idea based on Lion Smart's Light Battery, which allows for an estimated rapid charging time of roughly 13 minutes while charging power remains constant at over 200kW (10 percent to 80 percent SOC). The method is currently being developed to charge in less than ten minutes.

Responses