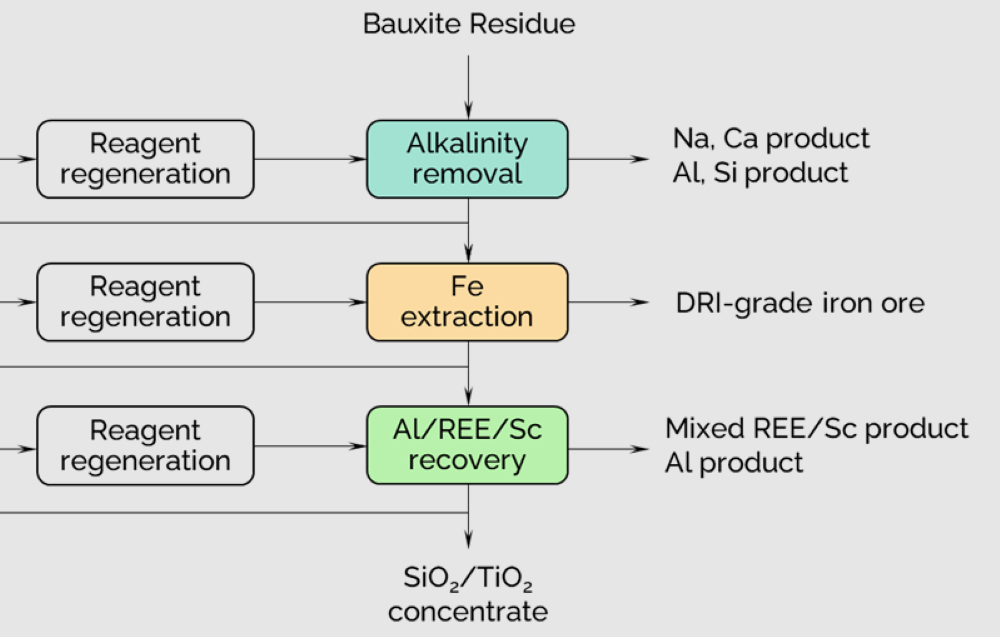

Geomega Resources, in partnership with Rio Tinto, has made significant progress on its bauxite residue valorisation pilot project, which was launched in March 2022. The process is structured into three sequential circuits, each undergoing individual testing and scale-up. Depending on the composition of their bauxite residue and strategic goals, refinery clients will have the flexibility to license Circuit 1 alone, a combination of Circuits 1 and 2, or the full suite of Circuits 1 through 3.

Pilot testing for Circuits 1 and 2 has been successfully completed, enabling Geomega to generate a representative residue sample required for the upcoming pilot work on Circuit 3, which is scheduled for 2025. To support this next phase, Geomega and Rio Tinto have extended their collaboration agreement, continuing the joint effort initiated with the project’s launch in March 2022.

In parallel, both parties are preparing for the next phase of development for Circuits 1 and 2, building on the strong results achieved so far. Further details on the upcoming steps will be shared once a formal agreement for this phase is finalised.

“Geomega’s research, engineering and the technical team have done an amazing job over the last 3 years to bring our bauxite residue valorisation technology from bench scale to a successful pilot scale operation. The improvements along the way made the technology more robust and flexible while paving the way for an economical solution. The aluminium industry needs such a technology to improve its long-term social and environmental impacts. On the other hand, the world needs a large and sustainable supply of critical metals that are found in these bauxite residues. Geomega’s technology unlocks both these opportunities while bringing potential long-term returns to the Corporation in the form of royalties, said Kiril Mugerman, President & CEO of Geomega.

This innovative technology tackles environmental challenges within the aluminium sector and supports a sustainable supply of critical metals, positioning Geomega for potential long-term financial gains. Each circuit in the process is designed with its own reagent recycling system, ensuring minimal effluent generation and eliminating the production of additional hazardous waste. A key advantage of Geomega’s technology is the high reagent recovery rate—over 95 per cent for Circuits 1 and 2—significantly reducing overall operating costs.

Geomega Resources Inc. is currently navigating financial headwinds, including negative cash flow and ongoing profitability challenges. Despite this, recent financing efforts aimed at supporting strategic initiatives in rare earth recycling offer a more optimistic outlook. Technical indicators also point toward potential upward momentum, though concerns around valuation persist due to negative earnings.

Over the past three years, Geomega has conducted multiple phases of bench-scale and pilot-scale testing to validate critical process parameters and generate product samples for further evaluation and optimisation. Throughout this development, Rio Tinto has supplied specific targets for product purity and particle size. These requirements have now been successfully achieved and verified by Rio Tinto’s technical team.

Geomega specialises in developing cutting-edge technologies for the extraction and separation of rare earth elements and other critical metals, with a strong emphasis on sustainability. Its solutions are applied to waste valorisation processes such as NdFeB magnet recycling, bauxite residue treatment, and sulphide tailings processing. The company’s strategy focuses on de-risking its technologies and collaborating with major industry players, positioning itself to create long-term value for shareholders.

Responses