Introduction

Guinea, a small West African nation with around 14 million population is endowed with 40 billion tonnes of low silica-medium alumina metallurgical grade bauxite resources. Most of the deposits are located within 100 to 150 km of coastline and well-developed river ports. At present Guinea is mining and exporting about 102 million tonnes of high-quality gibbsitic bauxite per annum, dominated by mining and infrastructure companies of China. There is only one alumina refinery in Guinea (Fria), which is being run by RUSAL with a quite low production capacity. Despite having such vast metallurgical grade bauxite resources, the alumina refinery projects are only existing on paper and drawing boards. There is a large potential to set up greenfield alumina refineries in this country. The article discusses the basic features of Guinea bauxite, how this is different from other lateritic bauxite of the world, the trend of high grading by mining companies, prospects of beneficiation and alumina growth potential.

{alcircleadd}2. Guinea Bauxite – Basic facts

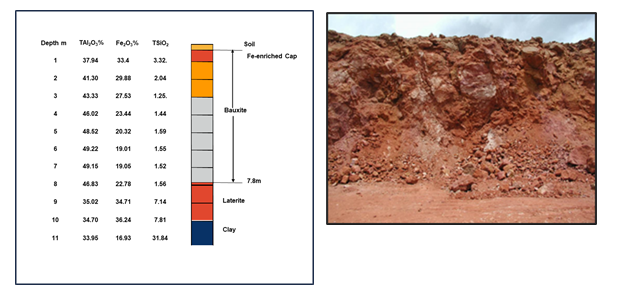

Guinea bauxite mostly occurs in low-lying flat-topped bauxite plateaus at an elevation of 200 to 400m above MSL. Bauxite occurs from the surface with thin soil cover (<0.5m) and low overburden (about 1m). The average thickness of the lateritic bauxite zone is about 8 to 10m. Guinea has natural low silica (2.5%) Gibbsitic Bauxite, where the reactive part is only 50% of total silica. Silica content almost remains constant in the laterite-bauxite profile and does not go down with the lowering of alumina as in the case of other lateritic bauxite deposits of the world. In this bauxite, monohydrates in the form of boehmite is, in general, lower than 2%. However, some of the Guinea bauxite have elevated Boehmite, Andalusite, Sillimanite and Pyrophyllite, which decreases the value of ore.

Fig.1. Main Bauxite Belt Guinea

Fig.2. A typical high-grade profile and bauxite orebody

3. Bauxite mining and beneficiation

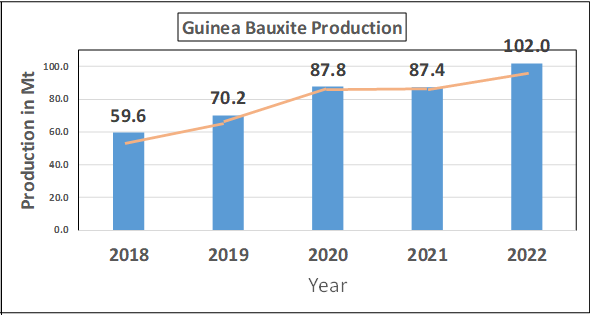

Guinea bauxite is easy to mine by a surface miner and/or drilling–blasting technique. The direct bauxite mining cost is normally less than US$3 per tonne and raw bauxite after simple crushing can be exported. Guinea has about 9 to 10 well-developed operating bauxite mines and each mine is different with specific bauxite quality, infrastructure, road/rail network and port/river jetty. As one can see in Figure-3, bauxite production is continuously increasing in Guinea and at present more than 100 million tons per annum of ore is produced.

Fig.3. Bauxite Production in Guinea

In absence of any ore conservation legislation in Guinea, it is observed that most of the mining companies selectively exploit high-grade bauxite resources, leaving the vast mineralized area of medium to low alumina, in the ground. These areas later on afforested and valuable resources are lost under the forest. This is not acceptable anywhere in the world. One of the bauxite plateaux of Guinea demonstrates how the high-grade bauxite are being exploited by some mining company, leaving a large area of medium-grade bauxite.

This selective mining practice was started by CBG by adopting a high alumina cut-off grade for resource estimation and continuing by major mining companies of Guinea. This practice should be stopped as large quantities of low to medium-grade bauxite otherwise suitable for alumina production, are left over on the ground. There must be also legislation to relinquish the exploited bauxite plateaus / deposits so that this can be allotted to other interested mining companies.

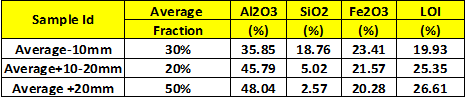

It is established that Guinea bauxite is amenable to simple dry beneficiation process and iron, particularly in the form of Goethite and silica as Kaolinite can be partly removed by rejecting fines. In one of the rejected bauxite heaps of in-situ lateritic bauxite of Guinea, the following average upgradation is observed on the elimination of 10 and 20mm fines.

Table:1. Bauxite Quality in Various Size Fractions in Lateritic Bauxite

It is observed here that alumina can be increased by 1.26 units and silica and iron can be brought down by 0.63 and 1.30 units respectively by simply rejecting 20mm fines by vibrating the screen. Dry beneficiation is quite prevalent in lateritic bauxite mines of India, particularly in Gujarat and Western India and industrial processes are shown below.

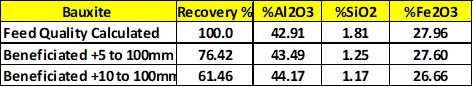

In some of the low-lying bauxite deposits of the Boffa area, transported bauxite deposits are identified. Here bauxite has high silica (6 to 8%) content and low alumina (40-42%). These bauxites are found suitable for upgradation by simple crushing and screening process.

Fig.4. Typical Transported Bauxite in the Boffa area

Here by simple dry beneficiation process most of the fine silica, both as kaolinite and quartz, can be removed as shown in the table given below.

Table:2. Dry Beneficiation of Transported Bauxite of Guinea

The above table shows a significant increase in alumina and a reduction in silica by simply eliminating 50% of fine materials, occurring as cement in the transported bauxite ore. The quantitative mineralogical analyses of fine-size fractions (<10 and 20mm) clearly showed the enrichment with kaolinite, fine-grained quartz and minerals like goethite and boehmite. There also exists the opportunity to extract bauxite values from the rejected fines (<20mm) by a wet beneficiation process. The geological mapping of deposits of Guinea, particularly those occurring below the bauxite plateaus, may reveal the presence of a similar type of transported bauxite in the low-lying areas.

4. Bauxite Processing Characteristics

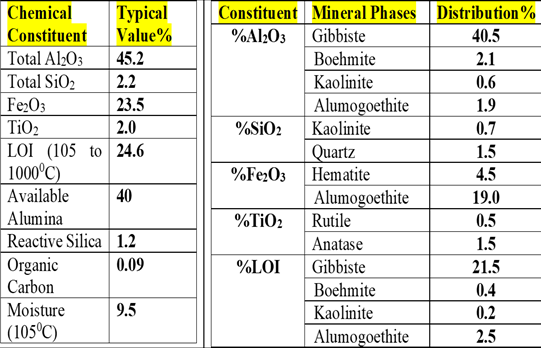

The majority of Guinea bauxite, particularly those occurring in Boke and Boffa areas, are suitable for low-temperature alumina refineries. A typical quantitative mineralogical analysis of Boke bauxite is shown below.

Table:3. Typical Quantitative Mineralogical Analysis of Boke, Guinea Bauxite

Guinea bauxite with 40 to 44% available alumina (A.Al) and 1.2-1.5% reactive silica (R.Si) can be considered one of the best ore in the world for alumina refineries. The main concern for low-temperature alumina refineries is the high Goethite-Hematite ratio in Guinea bauxite causing settling issues in the plant and increasing consumption of costly flocculants. Impurities and organic carbon content are quite low in Guinea bauxite almost similar to the best lateritic bauxite of India and Brazil. As about 50% of silica is in the form of quartz in Guinea bauxite, the fine quartz mineral grains cause abrasion in pipelines in plants and this increases the maintenance cost. Further Guinea bauxite is slightly harder and has a bond work index of about 11 to 12 kWh/ton compared to 9-10kWh for India’s Odisha bauxite and softer washed ores of Trombetas, Brazil and SMHL/Vimetco, Sierra Leone. Some Guinea bauxite also has elevated Boehmite, Andalusite, Sillimanite and Pyrophyllite, which decreases the value of ore. By dry beneficiation process, silica can be brought down to below 1% in Guinea bauxite, therefore this ore can be best used by blending with local high silica low-grade aluminous laterites in India and China.

5. Why are alumina refineries not constructed?

Despite having vast metallurgical grade bauxite resources, Guinea has only one old alumina refinery, constructed in the sixties, based on Aluminium Pechiney technology of atmospheric digestion similar to the NALCO Damanjodi plant. The installed capacity of this plant is 680,000 tons/ annum but presently this old plant is not producing more than 200,000 tpa. Although Govt. of Guinea (GoG) keeps insisting mining companies set up alumina refineries, often following reasons are cited:

5.1 Country Risk: Like some other African countries, Guinea has a history of alternate democracy and military coup. On September 5, 2021, the Guinean military, led by Colonel Mamadi Doumbouya, deposed President Alpha Condé in a coup d’etat. Although there is no change in the business environment, Guinea is considered a high-risk country. CBG is mining and exporting bauxite for the last 40 years and bauxite, and gold mining/export was never stopped due to political upheaval but it is difficult to get away from this perception. Present Government is showing a strong will for local value addition and insist bauxite mining companies set up alumina refinery.

5.2 Poor Infrastructure: Recently mining companies have built several roads/rail lines and river ports in Guinea mainly for bauxite export. These infrastructure facilities are fully occupied as the country is exporting more than 100mtpa bauxite. Guinea overall has poor infrastructure; there is no well-developed large deep-sea port and electric power infrastructure is also inadequate in the country.

5.3 Lack of Energy Sources: Guinea does not have any known energy source and the country is dependent on generators and small hydel power plants for electricity. Although talks are going on for the supply of LNG; there is no progress on the ground. Although the alumina refinery does not require a large power plant, the generation of steam and electricity for running the refinery/ township is essential. It will be necessary to set up dedicated greenfield coal or gas-based cogeneration steam-power plant for the alumina refinery in the absence of a renewable energy source.

5.4 Raw Materials: Alumina refinery requires a regular supply of caustic soda, lime, flocculants, sulphuric acid and filter cloths etc. All these raw materials including coal for the co-generation power plant, necessary for alumina production, have to be imported. Except for bauxite and water, no other raw materials are available in the country.

5.5 Qualified Manpower: A country like Guinea in West Africa lacks industrial culture as there are no large production plants in this part of the world. Educational institutes are also limited in Guinea and people must be trained abroad to efficiently work in a chemical plant. There is a clear shortage of skilled manpower in this country. About 4-5 years back, the proposal was submitted to set up Bauxite-Alumina Institute in Guinea, however, due to lack of support, this remained in paper only.

6. Future alumina potential

Despite some negative points, there are several advantages to setting up greenfield alumina plants in Guinea and some of them are highlighted here.

6.1 Availability of Land & Water: Guinea has plenty of suitable land for an alumina refinery along with enough sources of water near the deposits and river ports. Land can be easily acquired for alumina refinery and associated ancillary industries.

6.2 Government Incentives: As the Government of Guinea (GoG) is keen on the value addition of bauxite in the country, they provide scores of benefits in importing equipment, machineries and raw materials for alumina production.

6.3 General Economics of Alumina Production: In one of the projects, it was estimated that the landed cost of bauxite at a pit head refinery will be within US$5 per tonne and alumina can be produced in the cash cost of about US$150-160 per tonne. In place of exporting 2.5 to 3 tonnes of bauxite for 1 tonne of alumina, it may be cheaper to import less than 1 tonne of raw materials like high-quality coal, caustic soda, lime and other input materials for the production of 1 ton of alumina in Guinea.

6.4 Environmental Legislation: Guinea has not yet formulated strict legislation for the disposal of bauxite residue and other waste products. However, it will be necessary to follow and maintain international standards like dry disposal of red mud and utilization of other waste products.

Investors can also look into the following advantages in Guinea:

7. Bauxite-Alumina Institute

As Guinea’s future and earnings are dependent on the bauxite-alumina industry, it is necessary to set up Institute in the country on the same line as in India and Jamaica to cater for the R&D requirements of the aluminium industry. This will be the knowledge centre of Guinea on Bauxite and Alumina, where young Guineans can be trained on bauxite exploration, mining, beneficiation, ore conservation, monitoring quality and quantity of export shipments and also prepare Guineans for the construction and operation of alumina plant. Setting up new alumina refineries in the country is not easy and companies often complain that there is not enough qualified manpower in Guinea. The proposed Institute will provide training to qualified Guineans in alumina technology, develop a process flow sheet and understand whole process technology. It is important to understand the CAPEX and OPEX of alumina production in Guinea and issues associated with the lack of energy sources and disposal of bauxite residue (Red Mud). The proposed Institute will not only monitor the quality and quantity of bauxite being exported but also check the environmental aspects, starting from bauxite mining, transportation and export. The Institute will publish periodic International bauxite prices, check the freight costs and monitor the prices declared by mining/exporting companies.

8. Conclusions & Recommendations

Responses