Aluminium without CO2 emission can be touted as one of the most crucial aspects of climate goals. Developing zero-emission technology for aluminium production can be called the need of the hour in which Hydro has developed a groundbreaking technology called HalZero, which can help produce primary aluminium without greenhouse gas emissions.

As per the reports, Hydro's HalZero manufacturing technology will invest in a new testing facility, supported by the government of Norway. With this move, Hydro is on schedule to provide zero-carbon primary aluminium pilot production by 2030.

"We know that demand for aluminium will increase, and aluminium without CO2 emissions will mean a lot for the climate goals. Today, the aluminium industry accounts for 2 percent of the world's CO2 emissions. We are aware of our responsibility and we want to take the lead in developing zero-emission technology for aluminium production," said Eivind Kallevik, Executive Vice President for Hydro Aluminium Metal.

The HalZero is a brand-new method developed by Hydro. From the procedure, only oxygen is released in place of carbon dioxide. If Hydro is successful in its endeavour, the aluminium sector may undergo a huge revolution. The properties of zero-carbon aluminium are crucial for the green transition. The metal is weather-resistant and lightweight, which makes it ideal for solar panels, electric automobiles, and building facades.

HalZero is being developed as part of Hydro's technological plan to cut back on emissions related to the manufacture of aluminium. HalZero is most suited for expanding output. Hydro is growing the usage of renewable power and testing green hydrogen throughout the value chain while simultaneously developing carbon capture and storage for its current aluminium smelters.

"The development of HalZero is our most groundbreaking technology initiative ever. This could be the first industrial production of primary aluminum without greenhouse gas emissions in the world. The plan is ambitious, and there is considerable risk. Therefore, we depend on the authorities to join us on the road to make a major investment," added Kallevik.

Decarbonising industrial sectors is one of the most significant contributions to lowering global greenhouse gas emissions. In Hydro's Technical Center in Porsgrunn, Norway, the HalZero technology has been in the early stages of development for the past seven years. The development of a test facility will be funded with NOK 141 million from the Norwegian government through the state-owned company Enova. A 400 million NOK investment is projected to be made in total.

"The technology that Hydro is developing here can contribute to significant emission reductions for the aluminium industry both in Norway and in other countries. Enova supports companies that take a lead in decarbonising industry, and we believe that HalZero can contribute strongly to reducing emissions from the aluminium industry," mentioned Kristian Nakstad, CEO of Enova.

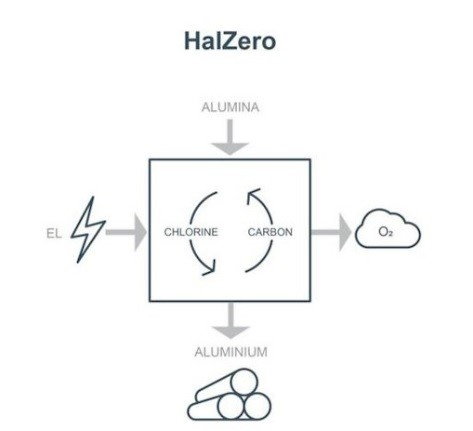

With the use of the Hydro HalZero technology, the smelting of aluminium will be decarbonised entirely, resulting in aluminium that emits no emissions from electrolysis or anode baking. The HalZero method converts alumina to aluminium chloride before electrolysis, keeping chlorine and carbon in a closed loop. Repeated recycling and reuse of carbon and chlorine results in reduced CO2 emissions and increased oxygen emissions.

Responses