您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

On December 17, 2023, Hyundai Mobis, the automotive parts subsidiary of Hyundai Motor Group, announced its readiness to commercialise an innovative battery cell cooling material. This breakthrough is poised to enhance both the charging efficiency and safety of electric vehicles.

The material referred to as "Pulsating Heat Pipe" is made of aluminium alloy tubes filled with refrigerants. These tubes, positioned between the battery cells in the module assembly, effectively dissipate heat, particularly during fast charging.

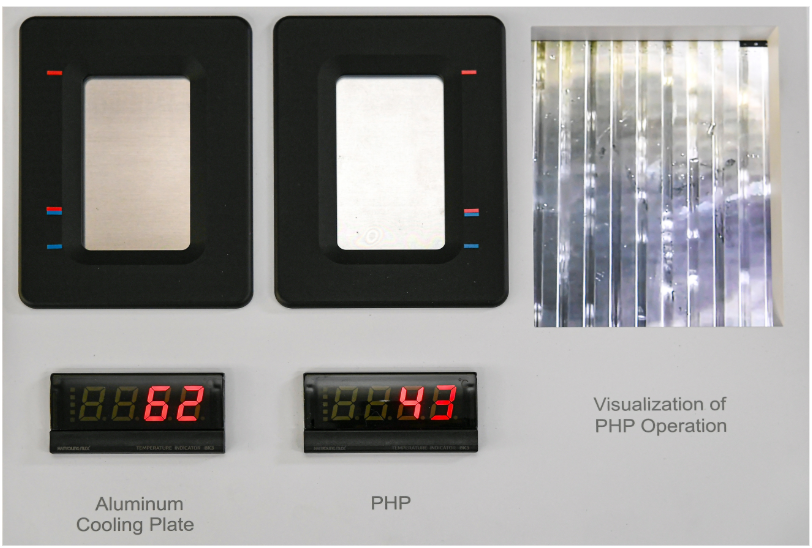

The above image reflects a comparison test of the heat dissipation performance of Hyundai Mobis' 'Pulsating Heat Pipe' for battery cell cooling and a standard aluminium cooling plate. It shows a temperature difference of nearly 20 degrees.

With a groundbreaking innovation in battery safety, the company revealed its intent to strengthen its footprint in the global EV market, even as the industry experiences a general slowdown.

Hyundai Mobis has introduced heat pipe coolers (PHP) into EV batteries for the first time, a technology previously used in devices such as personal computers and smartphones. In this system, refrigerants flow and oscillate within the pipes, transferring heat to cooling blocks to effectively stabilise the battery module's temperature.

An official at Hyundai Mobis said they plan to contact global carmakers to promote the new technology, "The new material will be used first for high-end EVs that require ultra-fast charging."

For mass production, the company streamlined the material's manufacturing process and reduced production costs, enabling its use in passenger car batteries. Additionally, the pipes are just 0.8 millimetres thick and significantly slimmer than the current 6-millimetre heat pipes, contributing to bulkier battery designs.

Image credit: Hyundai Mobis PR

Information credit: Hyundai Mobis PR

Responses