Indian Railways has cancelled its INR 30,000-crore tender for the production and upkeep of 100 aluminium-bodied Vande Bharat trains, according to Olivier Loison, Managing Director of Alstom India, stated to one of India's No. 1 financial and business portals.

Indian Railways is the fourth largest Railway network in the world after the US, Russia and China. The Vande Bharat Express is a semi-high-speed train service operated by the Indian Railways.

Loison said, “Indian Railways has cancelled the tender. However, with our strong local knowledge and investments in industrial and human capital over the years, we are well-positioned and committed to supporting the realisation of this vision of the railways in the future, should the opportunity arise.”

In disagreement over the bid price

Railway officials found the French multinational company Alstom India's bid price of INR 150.9 crore per train too high. They recommended capping it at INR 140 crore. Despite this, Alstom India aimed to finalize the deal at approximately INR 145 crore per train set. Alstom had been the lowest bidder for the INR 30,000-crore tender opened on May 30, 2023. Their bid, which covered the manufacture of all 100 Vande Bharat rakes, was detailed in documents reviewed by the business portal.

"The cancellation of the contract helps Indian Railways to buy more time to get the best possible prize. The bidders, too, will be better prepared to set up adequate manufacturing facilities,” an official said.

In July 2023, Alstom's CEO, Henri Poupart-Lafarge, announced that the company would implement new aluminium technology for the project and emphasised that it had offered a competitive price.

According to an official source, a contract was previously awarded to manufacture 200 Vande Bharat sleeper train sets, all constructed from stainless steel, at a cost of INR120 crore per rake.

The importance of competition

Another official emphasised that competition is crucial to securing the best price. They mentioned that the upcoming round of tenders would invite multiple participants, unlike the recent process that only involved two bidders, to ensure the timely production of the train sets.

The first official outlined the eligibility criteria for the tender, which requires companies to have a research and development (R&D) facility to ensure they can manufacture a prototype, along with the capacity to assemble at least five train sets per year.

In total, 100 train sets are to be delivered over a period of seven years. The consortium, a key player in the tender process, includes Swiss railway rolling stock manufacturer Stadler Rail and Hyderabad-based Medha Servo Drives. They were the only other bidder besides Alstom India, with an approximately INR 170 crore bid per train set.

According to the contract terms, the winning bidder will receive INR 13,000 crore upon delivery of the train sets, with the remaining INR 17,000 crore allocated for maintenance over the next 35 years.

What is the advantage of aluminium over stainless steel?

Aluminium train sets are lighter and more energy-efficient compared to those made of stainless steel. Aluminium is poised to revolutionise railway architecture, from coaches and wagons to signalling infrastructure and station furnishings. Thanks to its corrosion-resistant properties, aluminium can significantly extend the lifespan of railway coaches, potentially reaching up to 40 years with reduced maintenance requirements. In comparison, the current trains used by Indian Railways have a lifespan of around 35 years, with aluminium offering an additional five years of service. Furthermore, aluminium coaches and wagons provide a higher salvage value when the metal is recycled at the end of its life cycle. Another key advantage of aluminium is its faster production process, allowing for quicker delivery of coaches and wagons.

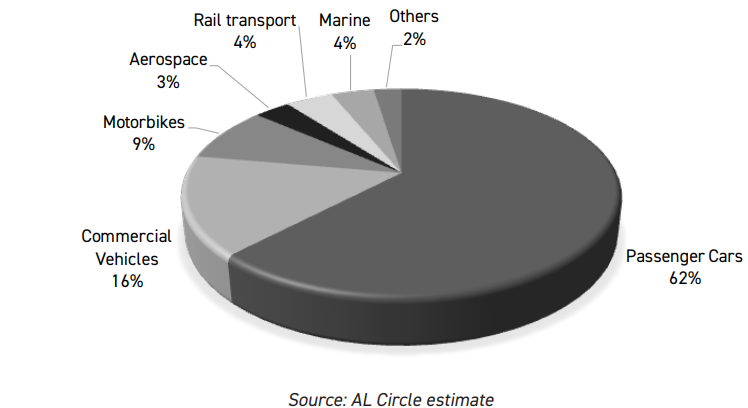

Forecast of global aluminium usage in transportation by end-use, 2023 (%)

Total usage: 27.5 million tonnes

While the initial cost of aluminium may be higher than that of standard materials, the long-term benefits for railways are undeniable. The potential for significant cost savings in the long run makes the investment in aluminium a financially sound decision for the railway industry.

The Indian Railways aims to introduce the first sleeper variant of Vande Bharat trains by the first quarter of 2025. Contracts have been awarded for producing 102 chair cars and 200 sleeper Vande Bharat train sets.

Responses