An energy and resource recycling firm in Japan is cooperating with the multinational Japanese carmaker Toyota to trial the use of aluminium and alloys recaptured in car manufacturing as a source of hydrogen generation for fuel cell electric vehicles.

Alhytec, A Toyama-based firm has bespoken a testing hydrogen generation plant in Toyama administrative region of Takaoka to use aluminium alloy chips collected from Toyota's engine and fuel cell tank manufacturing plants in Aichi area. The company focus to commercially develop a hydrogen generation unit with the usage of aluminium and alloys for marketing to industrial facilities.

The reaction of aluminium and water can produce hydrogen. Aluminium hydroxide, the by-product generated from the process can also be utilised in the production of various chemical and industrial materials. Such a recycling process, if materialised locally, does not require any hydrogen storage and transport infrastructure.

In 2015, a group of local Japanese firms came up with a roundtable discussion to study the potential of hydrogen energy businesses by treatment of aluminium and alloys. The participants included Alhytec and aluminium construction materials maker Sankyo Tateyama, both based in Toyama. Toyama was also home to energy-intensive aluminium smelters, who utilised the advantage of low-cost hydroelectricity generated in nearby mountain areas before they closed down. Toyama pursues to house various aluminium-consumer industries.

However, Japan no longer produces aluminium ingots locally after the country's last aluminium smelter, Nippon Light Metal's Kanbara smelter, collapsed in 2014. The country's aluminium imports plunged by 8% on the year to 1.4 million tonnes during the April 2019-March 2020 fiscal year.

Toyota has worked with Alhytec in technology development for hydrogen generation, to establish more efficient use of aluminium chips generated daily in its manufacturing process. The company has also been participating in initiatives to build a hydrogen supply chain and promote hydrogen businesses as part of efforts towards a decarbonised society.

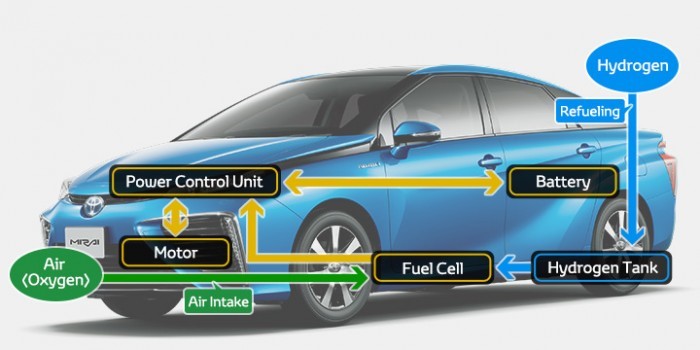

On 9th December, Toyota rolled-out the Mirai FCEV, designed to have an 850 km cruising range without needing to refuel, around a 30% improvement in cruising range over the first-generation Mirai launched in 2014 as the world's first mass-produced FCEV.

Responses