Jindal Aluminium Ltd (JAL) is plotting to spend between INR 100-150 crore to expand the production capacity of its Bhiwadi plant by 60,000 tonnes per annum, according to Pragun Khaitan, the company's vice-chairman and managing director.

This investment follows a previous investment of INR 250 crore in 2022 and an initial INR 100 crore in 2021. The total investment of approximately INR 500 crore will help JAL meet the growing demand for its products.

{alcircleadd}

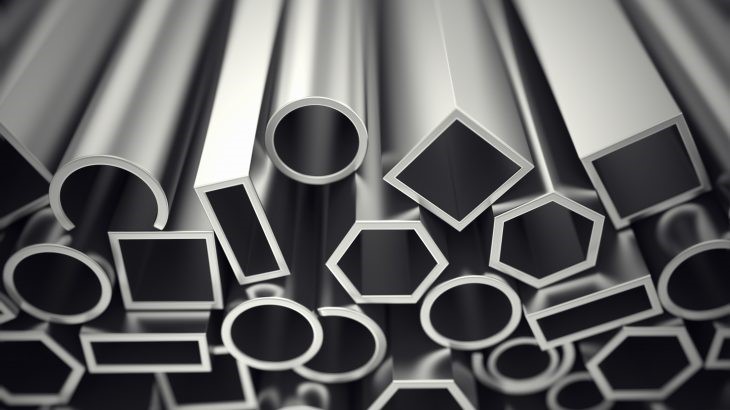

Momentarily, with a capacity of 1.25 lakh tonnes per annum, Jindal Aluminium is India's largest aluminium extrusion company. They have a significant share in India's extrusion market and are the country's largest manufacturer.

MD Pragun Khaitan exclaimed: "The way demand is growing, I think we need to work on all cylinders in terms of growth, and these investments will help us achieve that. Jindal Aluminium is India's largest aluminium extrusion company with a current capacity of 1.25 lakh tonnes per annum."

"They have a major share in India's extrusion market and are the largest manufacturer in the country. They are focusing on new opportunities in domestic manufacturing and are continuously increasing their share in the export market," Khaitan added.

JAL is focused on exploring new domestic manufacturing opportunities and increasing its export market share. The company plans to invest heavily in innovation and R&D to reduce costs, streamline processes, and reduce waste. JAL is committed to being a state-of-the-art and globally competitive company.

They will concentrate on capital expenditure construction and technical manufacturing, with the aim of expanding into other markets, such as railways, in the long term.

In the next ten years, India has been prophesied to grow at a CAGR of 10-11%, and Khaitan promises that JAL will be leading the industrial revolution. At present, India's domestic aluminium production rate can suffice the internal demand with a collection of 4 million tonnes each year.

JAL is ready to invest exponentially in innovation and R&D to curtail process waste, rectify its production line and decrease carbon emissions. They wish to implement every possible technology to reduce production expenditure.

"We are primarily concerned about advancing technology, increasing productivity and controlling manufacturing costs," the company officials remarked.

Pragun Khaitan went on to elaborate: "Our entire focus is on making it state-of-the-art; The lowest cost, best quality extrusion facility, maintaining the quality of extrusion coming out of this facility, in terms of technology intervention, in terms of plant design, in terms of facility construction, in line with all global standards."

"Our emphasis is that we are not benchmarking ourselves with Indian competitiveness. We are benchmarking ourselves with global competition," he concluded.

Responses