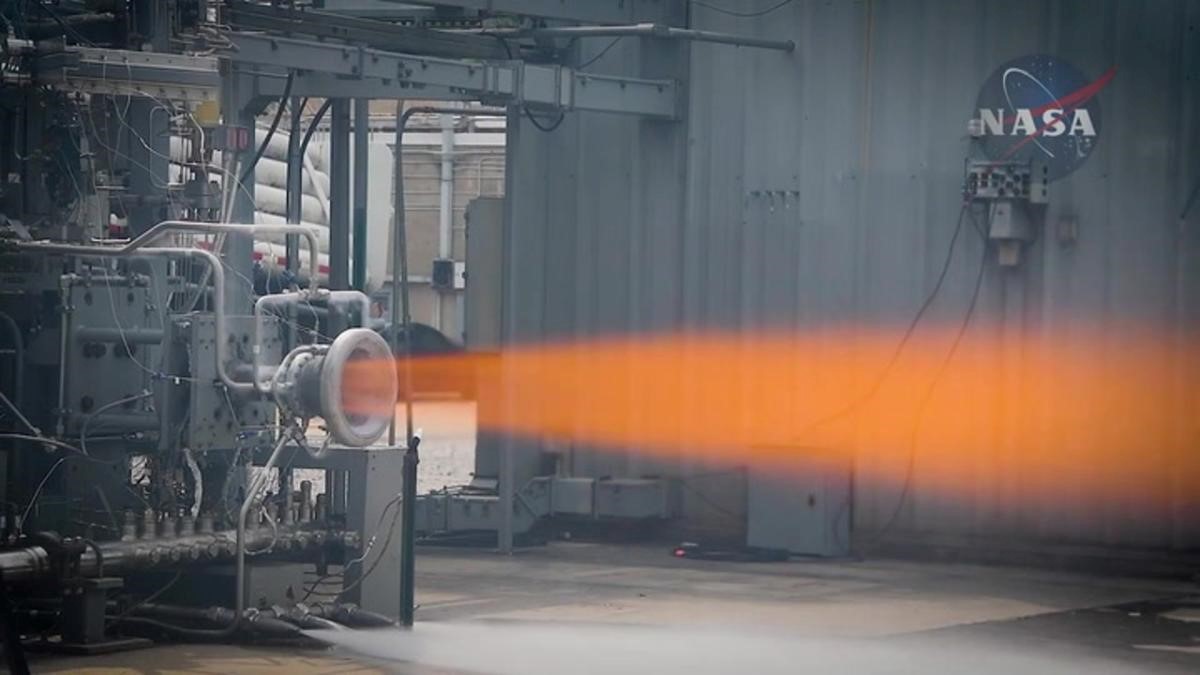

In a current development, NASA announced the successful testing of two 3D-printed aluminium nozzles that can withstand the high temperatures and extreme pressure associated with deep space launches.

The aluminium nozzles were tested at the Marshall Space Flight Center in Huntsville, Alabama. They demonstrated their ability to operate for almost 10 minutes during multiple hot fire tests using liquid oxygen and liquid hydrogen, as well as liquid oxygen and liquid methane fuel configurations with pressure chambers in excess of 825 pounds per square inch.

The development of lightweight rocket engine components that can bear high structural loads is of great importance to space exploration, as this would allow NASA to send more cargo to deep space destinations.

RAMFIRE principal investigator at NASA's Marshall, Paul Gradl, underlined through a conversation: "This test series marks a significant milestone for the nozzle."

"After putting the nozzle through the paces of a demanding hot-fire test series, we've demonstrated the nozzle can survive the thermal, structural, and pressure loads for a lunar lander scale engine," Gradl exclaimed.

The aluminium nozzle is a significant development in this regard, as it is lower in density and, therefore, high in strength while still being lightweight. However, the use of aluminium for additive manufacturing of rocket engine parts has been limited due to its low tolerance for extreme heat.

To address this issue, NASA's Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) project was launched, giving birth to a weldable type of aluminium that is heat-resistant enough for use on rocket engines.

The principal technologist for NASA's Space Technology Mission Directorate, John Vickers, illustrated: "Mass is critical for NASA's future deep space missions."

"Projects like this mature additive manufacturing along with advanced materials, and will help evolve new propulsion systems, in-space manufacturing, and infrastructure needed for NASA's ambitious missions to the Moon, Mars, and beyond," Vickers added.

The RAMFIRE nozzle is designed with small internal channels that keep it cool enough to prevent melting. The nozzle is also built as a single piece using advanced 3D printing methods, requiring far fewer bonds and significantly reducing manufacturing time compared to regular manufacturing, which may require as many as a thousand individually joined parts.

Paul also notified: "We've reduced the steps involved in the manufacturing process, allowing us to make large-scale engine components as a single build in a matter of days."

Furthermore, the RAMFIRE aluminium material and additive manufacturing process have been utilised to construct other rocket components, such as a 36-inch diameter aerospike nozzle with complex integral coolant channels and a vacuum-jacketed tank for cryogenic fluid applications. This is a significant advancement in the field of rocket engine nozzle technology that will enable the development of more efficient and cost-effective space exploration missions.

Responses