HRL Laboratories research center sold its first order of 7A77 aluminium 3D printing powder to NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Alabama. The material was sold by HRL Additive, a newly established 3D printing entity from HRL Laboratories just one week after the commercial launch of the product. The company would supply the aluminium powder to the aerospace and automotive sectors.

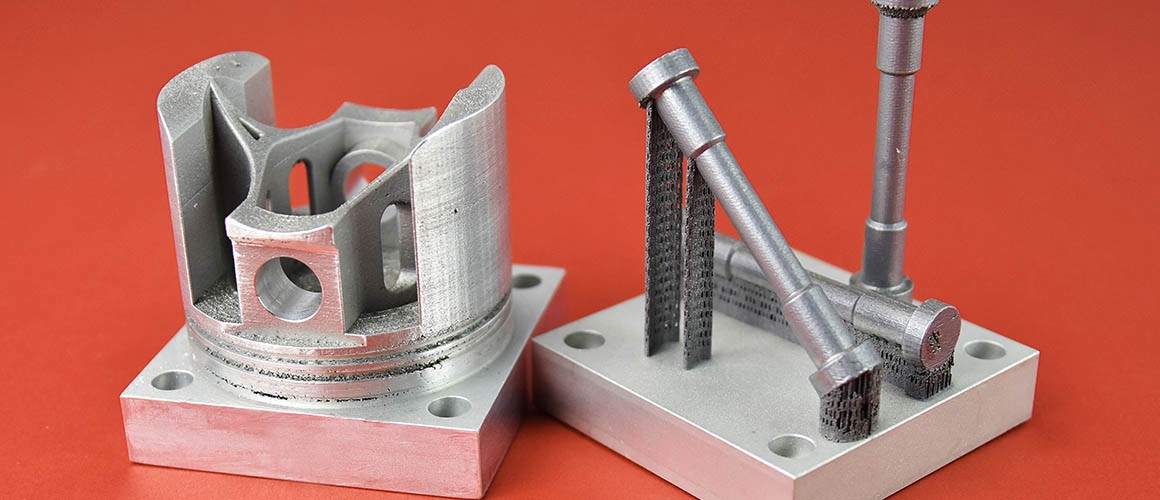

MSFC aims to explore the potential of 3D printing large-scale aerospace components using 7A77 powder.

“Certainly, the 7A77 feedstock powder could unlock the production of large-scale components produced via fusion-based additive manufacturing,” explained Omar Rodriguez of NASA’s Marshall Space Flight Center.

HRL Laboratories is jointly owned by General Motors, and the Boeing aerospace corporation. The started the development process for 7A77 aluminium powder in 2014, when researchers in HRL intended to create a 3D printable version of Al-7075, a traditionally non-weldable and commonly used aluminium alloy for high-stress applications. In September 2017, the HRL Laboratories team published a paper announcing that they had succeeded in 3D printing the non-weldable, high-strength aluminium alloy. The HRL research team made the tough but brittle alloy compatible with additive manufacturing in order to expand its applications across high value sectors like aerospace, automotive and oil & gas.

7A77 feedstock powder is now the first additive manufacturing aluminium alloy registered with the Aluminum Association. Customers can now buy the 7A77 aluminium powder from HRL for use with standard “off-the-shelf” 3D printers.

“Our goal is to provide the highest quality powder to HRL’s LLC members in the aerospace and automotive industries, as well as other commercial customers,” said Zak Eckel from HRL Additive.

MSFC plans to conduct research around 7A77 aluminium feedstock powder and 3D print different sized test parts with the powder using fusion-based additive technology before subjecting them to rigorous assessment.

NASA MSFC has a long history of developing additive manufacturing for aerospace. If successful the 7A77 aluminium powder will be a part of its additive manufacturing facility for aerospace related products.

Responses