Aluminium is a magic metal. Every day, this recyclable and sustainable metal is uncovering a new dimension. This time researchers at NIST have discovered unique atomic structures known as quasicrystals in 3D-printed aluminium alloys.

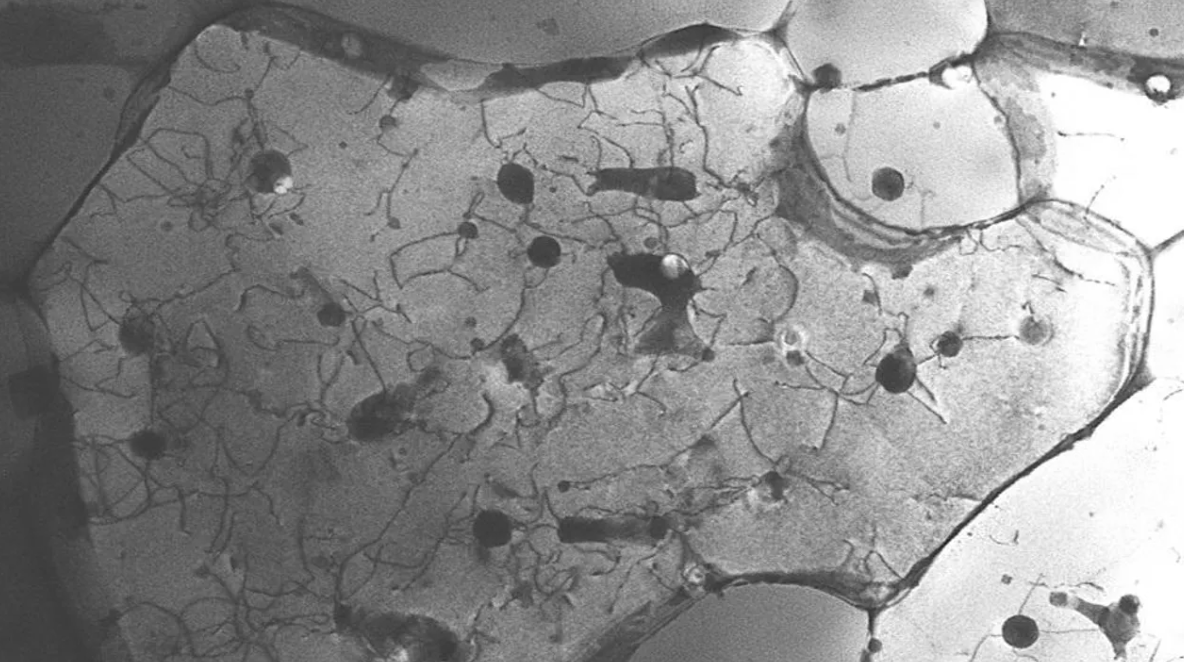

Found by materials research engineer Andrew Iams when he noticed something highly unusual while examining a sliver of a newly developed aluminium alloy under his electron microscope. At the atomic scale, the atoms appeared arranged in a remarkably unique pattern resembling quasicrystals.

“That’s when I started to get excited,” said Iams, “because I thought I might be looking at a quasicrystal.” However, Andrew Iams intuition proved correct. Iams and his team at the National Institute of Standards and Technology (NIST) not only confirmed the presence of quasicrystals in the aluminium alloy but also discovered that these complex structures contribute to enhancing its strength. Their groundbreaking findings have been published in the Journal of Alloys and Compounds.

The alloy took shape under the intense conditions of metal 3D printing, an advanced technique for manufacturing metal components. By understanding this aluminium alloy at the atomic level, researchers can unlock an entirely new class of 3D-printed parts—ranging from aircraft components and heat exchangers to car chassis. This discovery also paves the way for future research into aluminium alloys that harness quasicrystals to boost strength and performance.

Now what are quasicrystals? Developed by Dan Shechtman in the 1980s, a materials scientist from the Technion-Israel Institute of Technology, Quasicrystals resemble regular crystals but differ in some important ways. Traditional crystals are solids made of atoms or molecules arranged in repeating patterns. A familiar example is table salt.

There are several methods for 3D-printing metals, but the most widely used is called “powder bed fusion.” In this process, a thin layer of metal powder is evenly spread across a surface. A high-powered laser then traces over the powder, melting it precisely where needed. Once a layer is complete, a new layer of powder is added on top, and the laser repeats the process. Layer by layer, the metal is fused into a solid, three-dimensional object.

This technique allows for the creation of complex shapes that would be impossible to produce using traditional manufacturing methods. A prime example came in 2015 when GE developed a fuel nozzle for jet engines that could only be made through metal 3D printing. The redesigned nozzle emerged from the printer as a single, lightweight piece—25% lighter than its predecessor, which had to be assembled from 20 separate parts. Since then, GE has manufactured tens of thousands of these nozzles, demonstrating that metal 3D printing isn’t just innovative—it’s commercially viable.

“Fivefold symmetry is very rare. That was the telltale sign that we might have a quasicrystal,” said Iams. “But we couldn’t completely convince ourselves until we got the measurements right.” To confirm they had a quasicrystal, Iams had to carefully rotate the crystal under the microscope and show that it also had threefold symmetry and twofold symmetry from two different angles.

“Now that we have this finding, I think it will open up a new approach to alloy design,” says Zhang. “We’ve shown that quasicrystals can make aluminium stronger. Now people might try to create them intentionally in future alloys.”

Aluminium typically melts at around 700°C, but during 3D printing, lasers must heat it to temperatures well beyond that—surpassing its boiling point of 2,470°C. These extreme conditions significantly alter the metal’s behaviour, especially because aluminium heats up and cools down much faster than most other metals.

In 2017, researchers from HRL Laboratories in California made a breakthrough in collaboration with UC Santa Barbara. They developed a high-strength aluminium alloy suitable for 3D printing by adding zirconium to the aluminium powder. This addition prevented the printed parts from cracking, resulting in a durable, reliable alloy that opened new doors for additive manufacturing with aluminium.

In metals, perfect crystal structures can actually be a weakness. Their orderly, repeating atomic patterns allow atoms to slide past one another more easily, leading to bending, stretching, or breaking. Quasicrystals disrupt this regularity, introducing imperfections that strengthen the metal by making it harder for atoms to move.

When Andrew Iams examined the crystals from a specific angle, he noticed something remarkable—they displayed fivefold rotational symmetry. This means the crystal can be rotated five different ways around a central axis and still appear unchanged, a hallmark of quasicrystals.

Images' source: 1st - NIST and 2nd - elfinadesign/Shutterstock

Responses