Oak Ridge National Laboratory researchers from the Department of Energy have designed and additively manufactured an elementary aluminium device that upgrades the capture of carbon dioxide emitted from fossil fuel plants and other industrial processes.

The solutions for lessening global emissions of heat-trapping greenhouse gases such as CO2 address the continued use of low-cost, domestic fossil fuel resources while mitigating potential climate impacts.

ORNL’s device aims at a vital challenge in conventional absorption of carbon using solvents: the process typically produces heat that can limit its overall efficiency. By using additive manufacturing, researchers were able to custom design a multifunctional device that greatly improves the process efficiency by removing excess heat while keeping costs low.

One of the most commonly used and economical methods for capturing CO2 is absorption, which places a flue-gas stream from smokestacks in contact with a solvent, such as monoethanolamine, known as MEA, or other amine solutions, that can react with the gas.

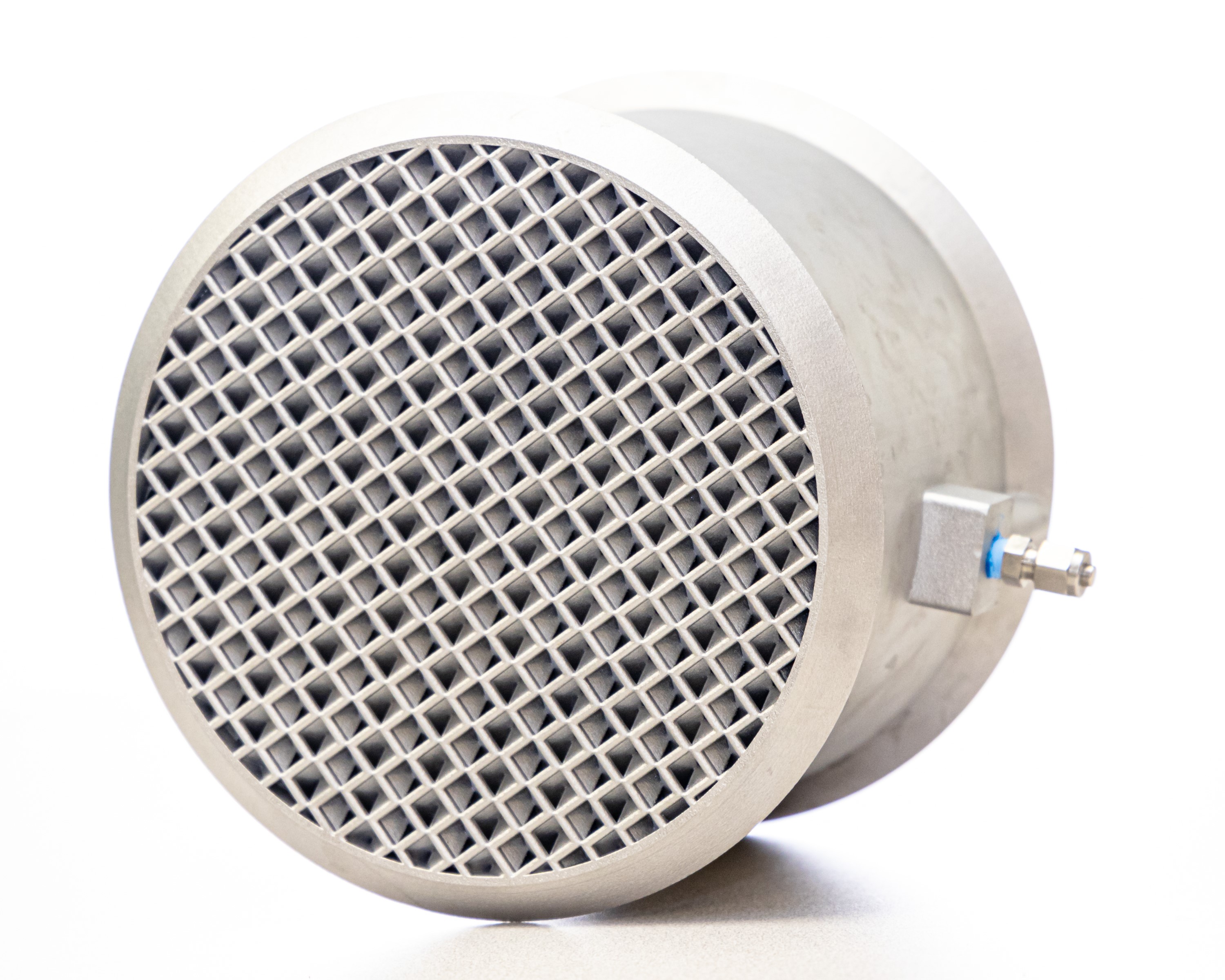

The research team tested the novel circular device, which integrates a heat exchanger with a mass-exchanging contactor, inside a 1-meter-tall by 8-inch-wide absorption column consisting of seven commercial stainless-steel packing elements. The 3D-printed intensified device was installed in the top half of the column between the packing elements.

Additive manufacturing facilitates to have a heat exchanger within the column, as part of the packing elements, without disturbing the geometry, thus maximizing the contact surface area between the gas and liquid streams.

Costas Tsouris, one of ORNL’s lead researchers on the project, said: “We call the device intensified because it enables enhanced mass transfer (the amount of CO2 transferred from a gas to a liquid state) through in-situ cooling. Controlling the temperature of absorption is critical to capturing carbon dioxide.”

ORNL’s Xin Sun, the project’s principal investigator, said: “Before the design of our 3D printed device, it was difficult to implement a heat exchanger concept into the CO2 absorption column because of the complex geometry of the column’s packing elements. With 3D printing, the mass exchanger and heat exchanger can co-exist within a single multifunctional, intensified device.”

Lonnie Love, a lead manufacturing researcher at ORNL, who designed the intensified device, said: “The device can also be manufactured using other materials, such as emerging high thermal conductivity polymers and metals. Additive manufacturing methods like 3D printing are often cost-effective over time because it takes less effort and energy to print a part versus traditional manufacturing methods.”

Both experiments produced substantial improvements in the carbon capture rate and demonstrated that the magnitude of the capture consistently depended on the gas flow rates. The study also showed a peak in capture at 20% of carbon dioxide concentration, with per cent of the increase in capture rate ranging from 2.2% to 15.5% depending on the operating conditions.

“The success of this 3D printed intensified device represents an unprecedented opportunity in further enhancing carbon dioxide absorption efficiency and demonstrates proof of concept,” Sun said.

Responses