On 25th February 2022, Robert Peterson, the CFO at the American multinational organization engaged in hydrocarbon exploration in the United States, the Middle East, and Colombia, Occidental Petroleum (OXY) claiming that its chemical division, OxyChem is planning to outdistance some chlor-alkali facilities to raise the capacity in the production of higher-value caustic soda.

The caustic soda produced by OxyChem is a vital constituent in the production of aluminium (bauxite processing to alumina), pulp and paper and is used in battery recycling.

However, in the fourth quarter of 2021, Peterson narrated OxyChem’s investment blueprint which reveals refurbishment of précised US Gulf Coast chlor-alkali facilities to transform from diaphragm-grade caustic soda to membrane-grade caustic soda production.

He further stressed to state that the carbon intensity in each tonne of caustic soda extracted can be narrowed and it can be allowed to deliver the scope for a remarkable diversification of existing capacity to fulfil the widening demand of the company’s vital products.

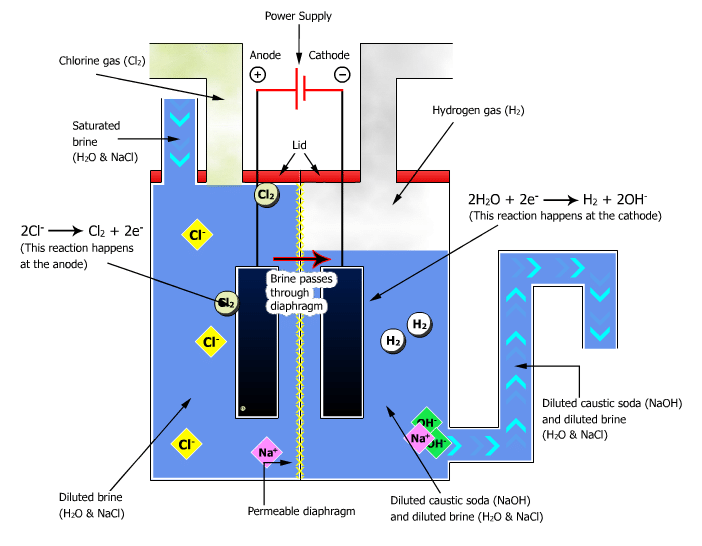

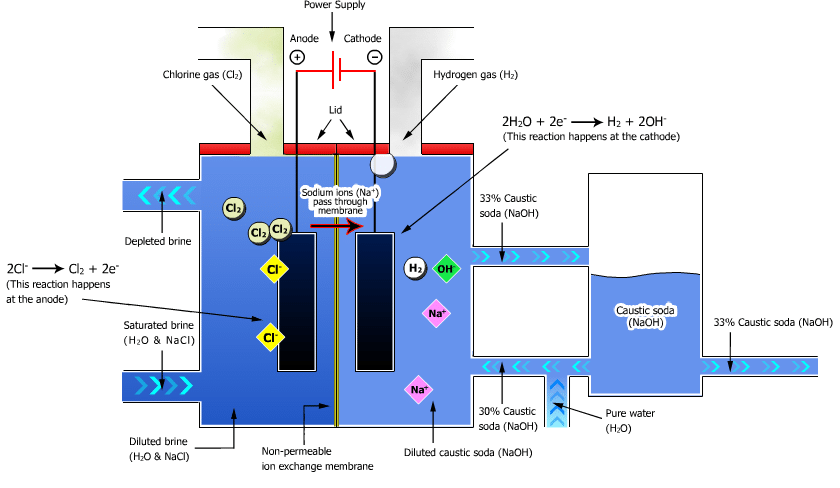

Having higher levels of impurities such as salt and iron, Diaphragm-grade caustic soda might be not pure but is being used for over 100 years worldwide. Meanwhile, Membrane-grade caustic soda is bereft of impurities though it has been in use only for 60 years at the most and is still evolving. The five of the significant US caustic soda producers, OxyChem, Westlake, Olin, Formosa Plastics USA and Shintech, only the first three produce both grades while the latter two prefer membrane-grade caustic soda.

During the third quarter of 2022, the company projects to permanently close down its remaining diaphragm-grade capacities, like the McIntosh and Alabama chlor-alkali unit, pushing diaphragm-grade shutdowns to 855,000 tonnes per year, since 2021.

Sodium Hydroxide Solution or caustic soda is used in the Bayer Process, the staple alumina extraction process followed by any production unit.

Responses