The Swedish automotive manufacturer Polestar has released its fourth Annual Sustainability Report, highlighting notable progress in reducing greenhouse gas emissions, advancing the Polestar 0 project, and enhancing transparency and material sustainability. Since initiating carbon footprint measurements in 2020, the company has achieved a 24.7 per cent reduction in emissions per vehicle sold.

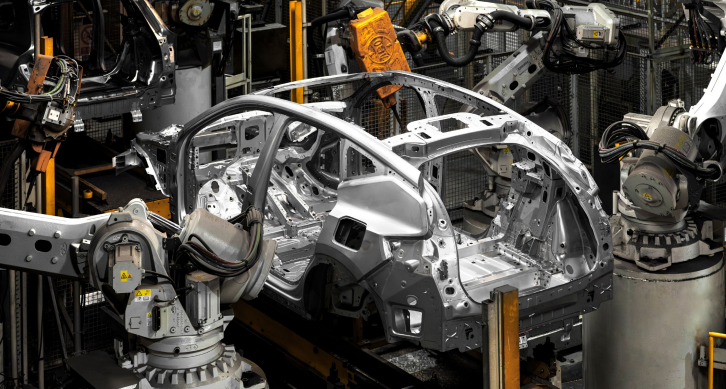

Key drivers of this progress include the expanded use of low-carbon aluminium across all models, improved battery manufacturing processes, the adoption of 100 per cent renewable electricity in vehicle production, and more efficient logistics supported by increased use of biofuels on select maritime routes.

Launched in 2021, the Polestar 0 project set out as an ambitious moonshot goal to develop a climate-neutral car—designed to spark urgency and drive collaborative innovation to support Polestar's vision of becoming climate-neutral by 2040. Today, Polestar and its project partners proudly report that their collective efforts have led to the identification of key low-carbon solutions, revealing the potential to produce a Polestar 2 with a carbon footprint 10 tonnes lower than at the project's inception.

The most significant emissions reductions have come from aluminium and steel manufacturing—critical materials for decarbonisation, as they account for approximately 45 per cent of the total cradle-to-gate carbon footprint of the Polestar 2. As the project enters its next phase, the Polestar 0 initiative will evolve, with areas requiring further research feeding into the Mission 0 House: a collaborative, Polestar-initiated research centre based in Gothenburg.

This hub brings together scientists from academia and engineers from industry to work jointly on eliminating greenhouse gas emissions from materials, products, and processes. A central principle of the Mission 0 House is the exploration and potential commercialisation of breakthrough solutions developed within its framework.

Circularity, inclusion, and transparency remain core focus areas for Polestar. The company has joined the Initiative for Responsible Mining Assurance (IRMA) and expanded its programme of onsite audits in high-risk regions. The traceability of critical materials has also been strengthened, including the mapping of manganese. Polestar continues to advance data availability and increase the use of recycled content across its vehicle programmes and model year updates—with Polestar 4 now incorporating 10 per cent recycled materials.

Image Source: Polestar sustainability report

Responses