The current year has seen 40 per cent jump in the price of pacifying a bit of uncertainty in financial markets. However, the price rise had some implications on industrial applications such as solar photovoltaic (PV) cell production.

Silver demand for solar applications increased about 23% in 2015 YOY. By 2050, PV is expected to be the world’s single-largest power generation source. Some of the companies are in the lookout for alternative materials and methods for the manufacturing of solar cells. In this effort, one company developed an aluminium foil cell and is seeking a partner to participate in the manufacture of a product that would generate electricity at a cheaper rate.

Taking this as an opportunity, one of the high tech companies, Natcore Technology Inc. has developed a technology that slashes the cost of solar cells by replacing silver with aluminium in order to make solar electricity generation available at a competitive price.

As told by Natcore President and CEO Chuck Provini, silver is chosen for electrical contact to solar cells, largely because of its high conductivity. Silver accounts for about half the manufacturing cost in a solar cell and 11% of total raw material costs. Aluminium, despite its high conductivity is about 99 per cent cheaper than silver.

{googleAdsense}

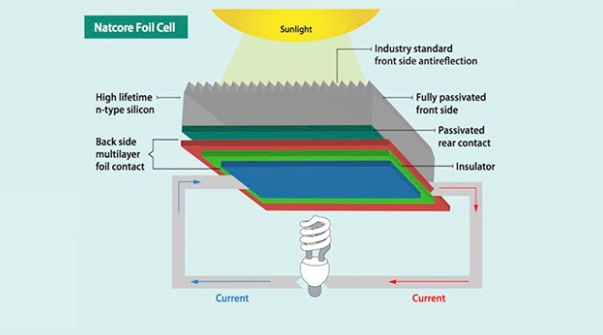

The scientists at Natcore use proprietary laser technology to substitute aluminium for silver to make a laminated aluminum foil PV cell. Technologically speaking, their Natcore Foil Cell is the first laser-processed, all-low-temperature solar cell that uses aluminium foil laminate to realize an all-back-contact system. By doing this, they’ve replaced high-cost silver with low-cost aluminium to create solar cells that are simpler and less expensive than traditionally manufactured ones.

“The key driver of solar electricity is cost,” explained physicist Dr. David Carlson, a member of the Natcore science advisory board.

“A lot of the costs of materials, such as silicon, have been driven down. Silver is still one of the major components and that is what Natcore is getting rid of. We would be using an entirely new manufacturing process, replacing silver with aluminium and simplifying the manufacturing process,” he adds further.

Natcore is in talks with major aluminium producers regarding this project but also has an interest in discussing with smaller companies who make value-added products using outsourced aluminium foil.

“If we joint venture with a solar cell manufacturer, we’ve got one partner. If we joint venture with an aluminium foil manufacturer or a company that converts it into other products, then we can retain our ability to sell to the whole universe of solar cell manufacturers,” he concluded.

Responses