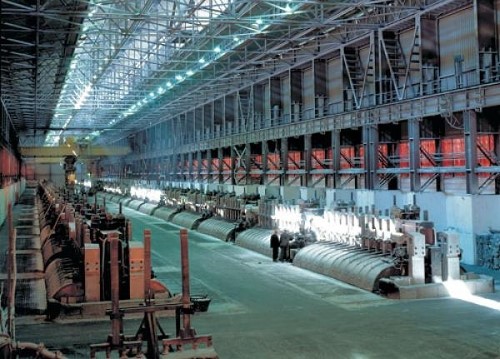

RUSAL has announced the launch of a potroom control system as part of its production efficiency improvement plan at some of its Siberian smelters. The system will use advanced scientific and methodological approaches based on a process of forecast analytics known as ‘BigData’. The project will require an investment amounting to around RUB 20 million.

Rusal plans to boost its aluminium production efficiency by implementing this system in the potroom in two ways:

{alcircleadd}

"The use of forecast analytics in potroom control is just one step towards our target that we have set within our R&D framework. If successful, similar approaches will be enrolled for analysis and to increase efficiency at other stages of the production chain. Such efficiencies will assist in minimising our energy consumption and improve our overall performance of the aluminium production,” said Viktor Mann, RUSAL’s technical director.

Rusal expects such a system will improve most of its processes and reduce limitation factors. Current inefficiency in reduction cell operations is caused by error in post operation analysis as they do not have control over an operation of efficient reduction cell in the optimum process window. Such limitations affect performance in both a potline and the whole smelter. The new system is expected to detect the causes of any reduced reduction cell performance, recognise the optimum conditions depending on the status of equipment and predict malfunctions well in advance.

a ‘BigData’ project will be first implemented at several smelters of RUSAL in Siberia as pilot projects. If it gives successful results, Rusal will roll it out to its other facilities.

Responses