According to a recent report, Showa Denko K.K., a Japanese chemical company, has decided to double Oyama Plant’s capacity to produce aluminium heat radiators for power modules used in electrified vehicles, including battery electric vehicles, hybrid vehicles, and plug-in hybrid vehicles.

As per the report, Showa Denko has started the installation of the additional production line, which is expected to begin operations at the beginning of 2022.

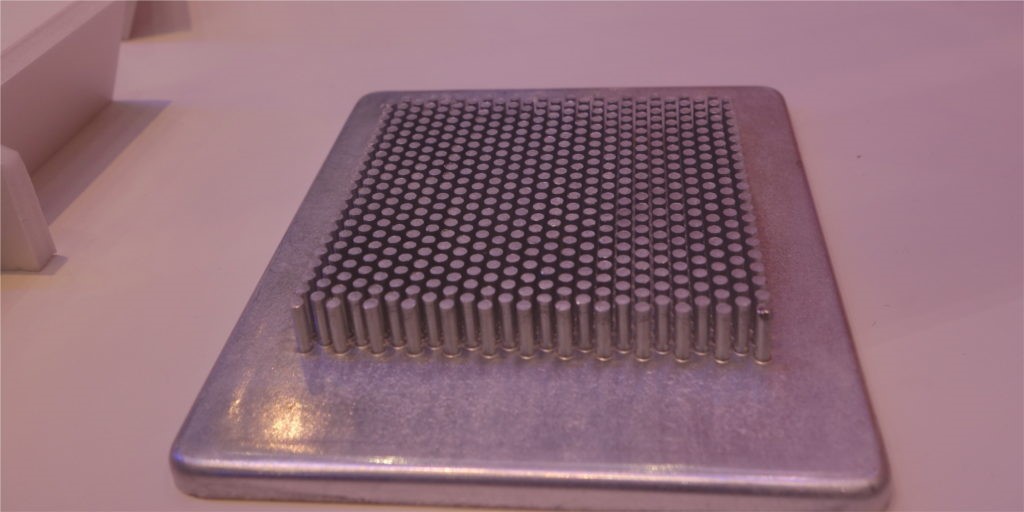

Aluminium heat radiators for power modules produced by Showa Denko adopt direct vacuum brazing between insulated substrates and other parts including aluminium fins produced by Showa Denko.

The company’s aluminium heat radiators for PMs are small, having large heat dissipation capacity and alloy-free design of coolant pipes, thereby having a multiplicity of uses. Now, Showa Denko will develop and produce smaller higher-performance heat radiators on the basis of its long-time fostered aluminium-alloy design technology, aluminium processing technology and power-module evaluation technology, expanding its aluminium specialty components business.

Showa Denko started producing aluminium heat radiators for power modules in 2019.

Showa Denko’s aluminium heat radiators are installed into power modules by a large power module manufacturer in Japan.

Showa Denko has decided to expand its aluminium heat radiators manufacturing capacity in response to the increasing demand for heat radiators, with the global automobile industry accelerating its shift towards XEVs.

Responses