您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

Japan’s Showa Denko (SDK) a producer of aluminium materials and high-value-added fabricated aluminium and aluminium cans in Japan has developed a technology to directly bond aluminium alloys to polycarbonate resin — a non-crystalline commodity engineering plastic.

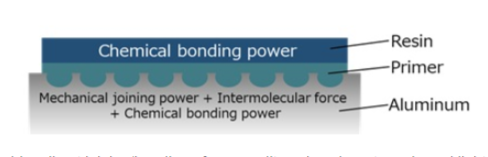

Normally aluminium alloys and polycarbonate resin are bonded by using bolts or an adhesive. In recent years, focus is being shifted to new technologies that directly bond resin materials with aluminium alloys through injection moulding or insert moulding.

These technologies are expected to simplify processes and increase productivity while making processing of complicated shape easier. In many cases, however, they depend on mechanical bonding, such as realizing an anchor effect through injection of resin over a roughened metal surface. Polycarbonate resin was so far not considered suitable for joining/bonding with metallic materials using these conventional methods.

A special primer is used to elevate bonding power between aluminium and amorphous polycarbonate resin.

SDK has enabled such direct joining/bonding based on its expertise in aluminium alloys and polymer chemistry. Specifically, it has developed a bonding technology based on special surface treatment and primer treatment for aluminium alloys.

Their tests show this technology can be used under ordinary polycarbonate injection moulding, providing sufficient bonding strength without separate conditioning.

This technology enables the direct bonding of commodity polycarbonate resin and light-weight aluminium and can be applied to smartphone housings. SDK will continue development work to optimize its aluminium-surface-treatment technology and primer-coating conditions in order to increase the strength and durability of the bonds. In the future, SDK plans to use the technology in automotive parts applications.

Responses