您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

With the growing demand for packaging with reduced plastic content and more eco-friendly materials, many organisations are developing sustainable solutions featuring aluminium as one of the key ingredients. In response to this demand, Hamed Zarei and his team designed and evaluated various paper-aluminium laminates, testing their strength and durability against traditional polyethylene-aluminium packaging.

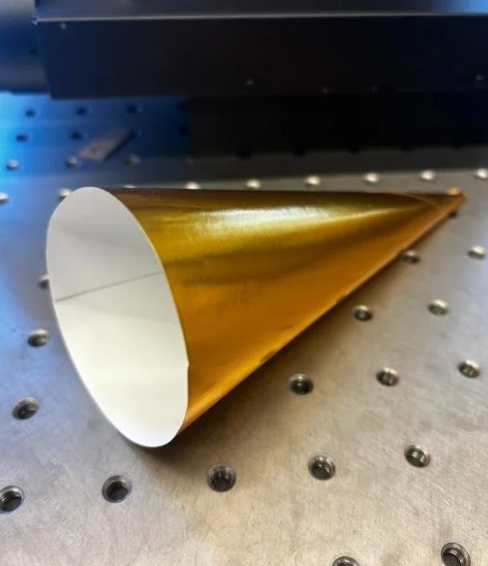

Image source: Hamed Zarei

As per the research published in ACS Omega, substituting plastic layers in takeout containers with paper could improve sustainability. Through mechanical testing and computer simulations, researchers explored paper-aluminium laminate designs that maintain durability and functionality. Zarei's team initially created two types of paper-aluminium laminates – A machine direction laminate (MD) and a cross-direction laminate (CD).

Two types of laminate

A machine-direction (MD) laminate, with aluminium and paper fibres aligned parallel to the loading direction (with the grain), and a cross-direction (CD) laminate, with fibres oriented perpendicular to the loading direction (against the grain). Researchers tested the tensile strength of these MD and CD laminates against conventional polyethylene-aluminium laminates by gradually applying force to samples with laboratory machines. Additionally, they developed a digital model, validated by tensile strength data, to simulate these stretching tests and reliably predict the material's behaviour under various conditions.

Outcome of the test

In the tests, the polyethylene-aluminium laminate demonstrated greater stretchability before breaking compared to both paper-aluminium laminates. Among the paper options, the MD paper laminate stretched further but developed cracks along the grain faster than the CD paper. Using simulations with MD, CD, and a mixed MD/CD paper on their digital model, the researchers predicted that combining aluminium with a paper layer containing both MD and CD fibres could achieve mechanical properties close to traditional polyethylene-aluminium laminates.

While the MD/CD paper-aluminium laminate has not yet been produced in the lab, this research provides valuable insights for packaging engineers aiming to develop sustainable materials with performance comparable to conventional options. The authors acknowledge support from the Tuscany Region Development and Cohesion Fund.

Responses