Sustainability partnership extended: EGA's CelestiAL-R aluminium continues in BMW vehicles

Emirates Global Aluminium (EGA), the world's largest producer of premium aluminium, has announced the extension of its CelestiAL-R supply agreement with the BMW Group for the coming years. CelestiAL-R is notable for being the world's first aluminium blend made using solar power and recycled metal.

The BMW Group incorporates EGA's CelestiAL-R in the production of high-quality aluminium components for its vehicles. To commemorate the renewal of this significant agreement, Oliver Zipse, Chairman of the Board of Management at BMW AG, visited EGA's facility in Jebel Ali and Dubai Electricity & Water Authority's Mohammed bin Rashid Al Maktoum Solar Park.

EGA's partnership with the BMW Group began in 2013, and the BMW Group became the first customer to source CelestiAL solar aluminium in 2021. Since early 2023, EGA has exclusively supplied the BMW Group with CelestiAL-R.

Under the renewed agreement, EGA will continue to supply tens of thousands of tonnes of CelestiAL-R annually, with a focus on significantly increasing the proportion of recycled metal in future deliveries.

Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium, said, "The BMW Group demands the highest quality metal produced with solar power, and this continues to drive our innovation at EGA. Over the coming years, we will further increase the proportion of recycled metal in our CelestiAL-R for the BMW Group while meeting their metal quality specifications. I thank the BMW Group for their trust in EGA."

Producing consistently high-quality aluminium from an increasingly diverse scrap mix presents significant technical challenges. To ensure its CelestiAL-R products meet exacting standards, EGA performs detailed chemical composition analysis through optical emission spectrometry at every stage of the production process. The company operates state-of-the-art metallurgy laboratories at its Jebel Ali and Al Taweelah sites.

EGA pioneered the commercial production of aluminium using solar power, a significant step in reducing the environmental impact of aluminium manufacturing. Notably, electricity generation contributes approximately 60 per cent of the global aluminium industry's greenhouse gas emissions.

EGA sources locally recycled aluminium from UAE-based suppliers and is constructing the nation's largest aluminium recycling facility at Al Taweelah. This plant, upon completion, will have an annual capacity of 170,000 tonnes of secondary billets, with the first hot metal expected by 2026.

The demand for aluminium is poised for significant growth in the coming years, primarily fuelled by an increasing preference for eco-conscious solutions across various sectors such as transportation, infrastructure, energy, and food security.

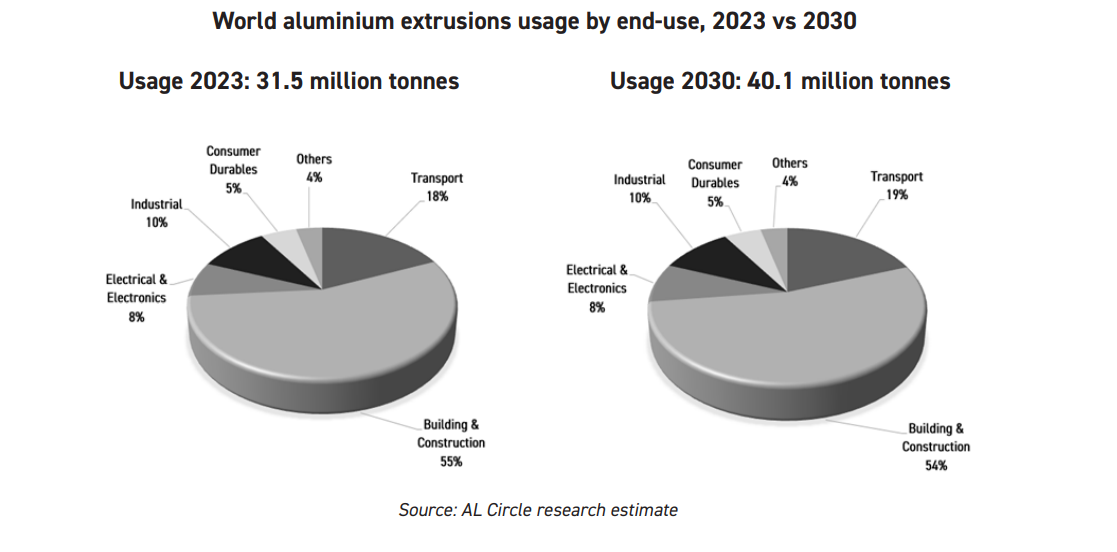

AL Circle's industry-focused report, "The World of Aluminium Extrusions - Industry Forecast to 2030", revealed that in 2023, the building and construction sector dominated the consumption of aluminium extrusions, comprising 55 per cent of worldwide usage. Following closely, the transportation sector accounted for 18 per cent, with the industrial sector trailing at 10 per cent. Projections suggest that in the coming seven years, aluminium extrusions' utilization in the building and construction sector will experience a compound annual growth rate (CAGR) of 3.05 per cent, while the transportation sector is expected to grow at a faster pace, with a CAGR of 4.31 per cent annually.

AL Circle's industry-focused report, "The World of Aluminium Extrusions - Industry Forecast to 2030", revealed that in 2023, the building and construction sector dominated the consumption of aluminium extrusions, comprising 55 per cent of worldwide usage. Following closely, the transportation sector accounted for 18 per cent, with the industrial sector trailing at 10 per cent. Projections suggest that in the coming seven years, aluminium extrusions' utilization in the building and construction sector will experience a compound annual growth rate (CAGR) of 3.05 per cent, while the transportation sector is expected to grow at a faster pace, with a CAGR of 4.31 per cent annually.

In 2023, China dominated the global market for aluminium extrusions, representing 66 per cent of total usage. Following behind were Europe with 10 per cent, the Rest of Asia Pacific with 9 per cent, North America with 8 per cent, and the Middle East and Africa with 4 per cent. The Asia Pacific region holds a significant market share, with China dominating and driving growth, mainly through its transportation sector. While the global building and construction sector is experiencing a slowdown, it remains a substantial contributor to the consumption of aluminium extrusion. Among other end-use sectors, transportation, industrial, electrical, and consumer durables play significant roles. Electric vehicle adoption is also significantly driving market expansion. Electric vehicle adoption is also significantly driving market expansion.

Don't miss out on essential insights – secure your copy of "The World of Aluminium Extrusions – Industry Forecast to 2030" and stay ahead in the market. Gain strategic forecasts, trends, and data to power your business decisions today!

Top image credit: EGA Press Release

This news is also available on our App 'AlCircle News' Android | iOS