The Aluminium industry is facing challenges in decreasing energy consumption and increasing the rate of recycling - Dynamic Concept

Context and challenges of the industry

The situation in terms of global climate change and greenhouse emissions represents a big challenge for our modern society – which requires both real actions and new solutions. More and more socially responsible groups and companies participate in this worldwide effort that also generates new opportunities.

{alcircleadd}Aluminium recycling is one piece of the puzzle to achieve the goal of ensuring a greener economy. Some materials are more difficult to recycle than others. It is the case for some post-consumer parts from the automotive industry, which contains specific alloys less compatible with current recycling practices. Therefore, complementary solutions are required.

Meanwhile, the industry is facing higher energy costs and this leads to increasing efforts towards energy saving initiatives. As a side benefit, this also comes with a reduction of greenhouse emissions.

Recycling and closed-loop economy

The availability of scrap has always been a challenge. In some regions, this type of scrap was shipped to recycling facilities equipped for the task. Still, the current trend is to minimize transportation and CO2 emissions by having local recycling facilities.

In many processes, an efficient way to recycle is to recover scrap generated in the same value chain. For example, an aluminium slab supplier can recover scraps from its customers and sub-customers to cast new slabs. The advantage of this is the compatibility of the products in terms of alloys and other characteristics. The required equipment is simpler, and the constant scrap supply is easier to guarantee.

For post-consumer scrap, the challenges are much more significant. The material can contain contaminants, such as paints and/or other unwanted elements.

For scrap handling, charging, treatment and melting, many options are possible depending on the recycled material type. Some require sorting and pre-treatment; others can be directly loaded. Many melting solutions are to be considered, such as rotating or multi‑chamber furnaces, post-combustion fume treatment, preheating requirements, etc.

Specific alloys for specific applications will complicate the integration in the remelting process. Essential quantities of metal are currently not being recycled because of this contamination.

The potential to recycle more scrap requires new solutions. Dynamic Concept has developed in alliance with Nature Alu, a state-of-the-art technology to purify aluminium. The primary purpose of this technology is to produce super high-purity aluminium.

However, the same technology can be used to purify contaminated aluminium.

Also, metal transfer is a crucial factor in the recycling process. In some existing plants, crucibles are already being used for molten metal transfer. Many options are possible, and Dynamic Concept has direct experience with most of them.

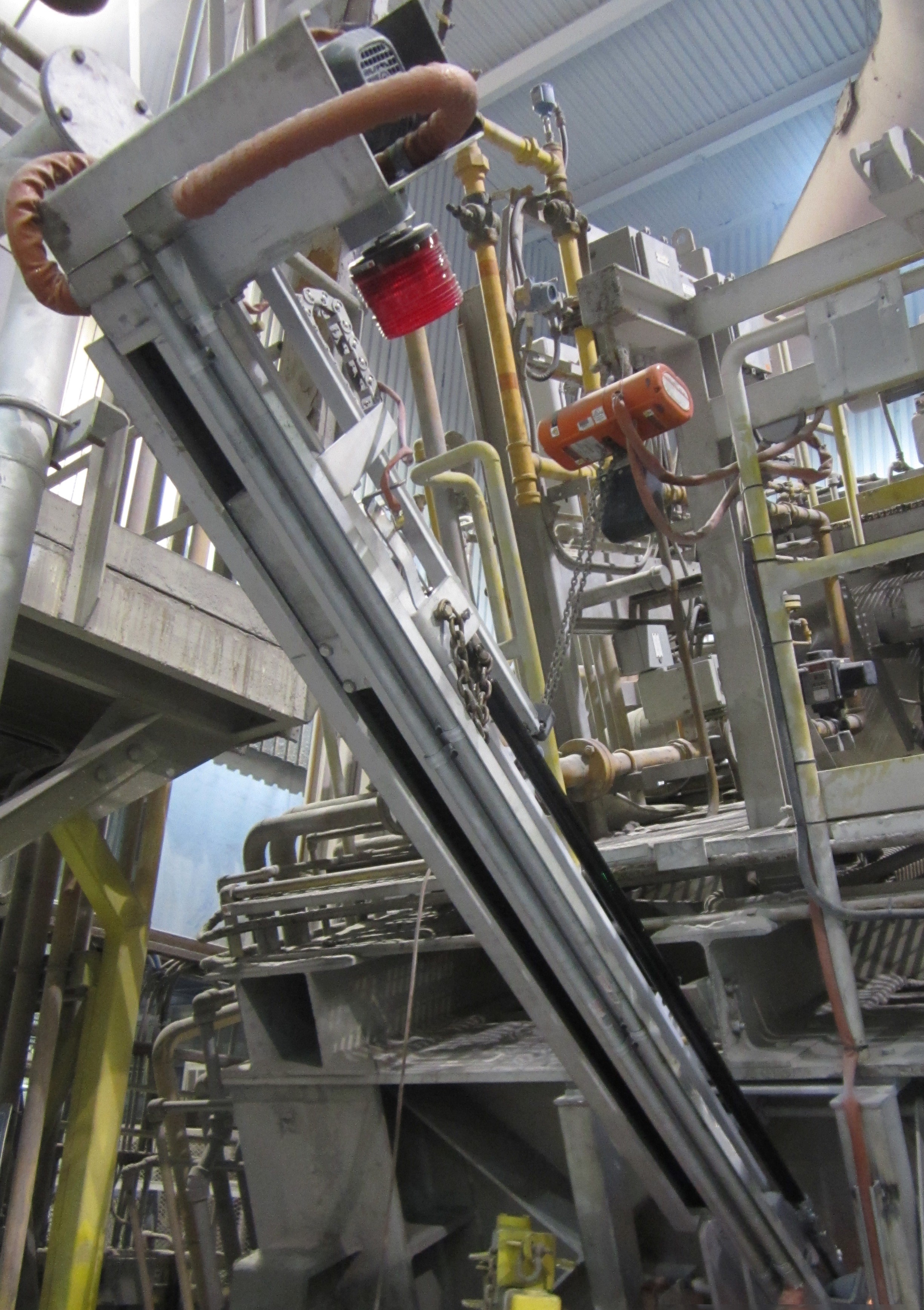

DYNAFEED FC: Furnace to Crucible Metal Transfer Siphoning System

Energy saving opportunities

Energy costs have increased significantly in the last year. Aluminium producers and foundries are looking for energy-saving solutions, and those potential savings are enormous, most notably in Casthouses.

Many gas-powered components are required to run a Casthouse. Dynamic Concept proposes and supplies a series of solutions specifically designed to save energy:

- Improved control of burner systems

- Optimized furnace process control

- Accurate & more efficient molten metal temperature monitoring

- Regenerative burners

- Furnace heat recovery

- Etc.

For example, the DynaProbe is a smart temperature reading system that allows accurate molten metal temperature readings into the metal bath at various depths. The furnace control system uses the collected data to enable predictive burner control, avoiding overshooting the required process energy for every cycle.

DYNAPROBE: Intelligent and Automated Thermocouple Mechanism

Conclusion

The aluminium industry is facing new challenges that can be turned into opportunities. The increase in recycling activities helps decrease overall greenhouse emissions as well as production costs. Working to save energy actually serves a dual purpose to achieve the same goals. Dynamic Concept is positioned to support aluminium producers by bringing technical support and solutions to those new challenges.

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)