The most common uses for aluminium aerospace extrusions

Aluminium is a prevalent material employed across various aerospace applications, finding its place in a wide range of components, including aircraft fuselages and engine parts. Its remarkable strength, low weight, and corrosion resistance make it an exceptionally well-suited material for the demands of aerospace engineering.

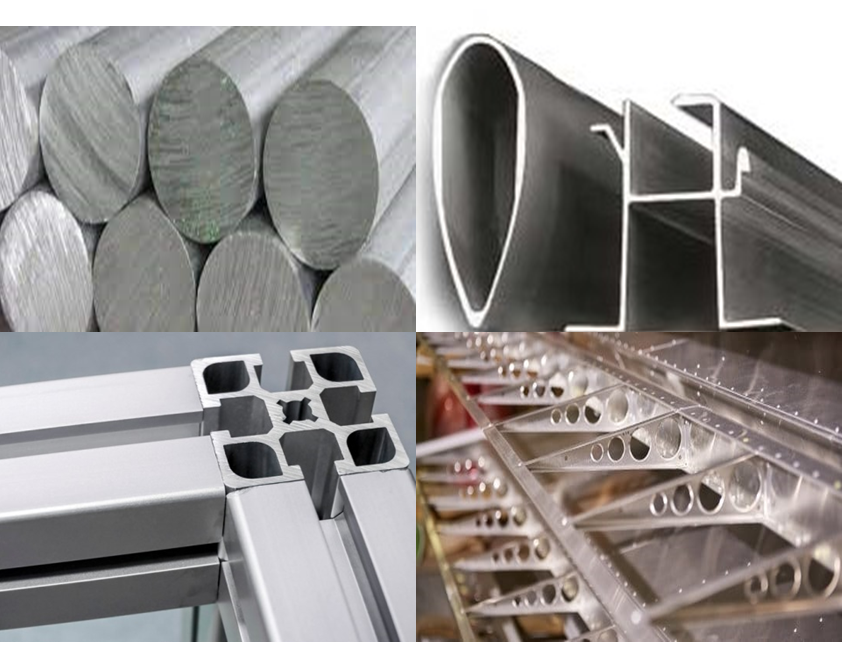

Aluminium aerospace extrusions refer to aluminium alloys that have undergone a shaping procedure known as extrusion. This process is chosen due to the malleability of aluminium alloys, allowing them to be easily heated and moulded into precise configurations.

The applications for aluminium extrusions are diverse and encompass aircraft manufacturing, the creation of window and door frames, and the production of components for the automotive industry. Aluminium extrusions are known for their ease of manipulation and can be connected through various techniques, including welding and riveting.

Aluminium aerospace extrusions find extensive application in the fabrication of aircraft and spacecraft due to their excellent combination of high strength relative to weight and resistance to corrosion. They are integral in constructing various components, from fuselage and wing skins to structural elements like stringers and spars.

The choice of aluminium alloys in aerospace is driven by their remarkable ability to endure extreme temperatures in space. These qualities make them exceptionally well-suited for use in aviation and space-related projects. Beyond aerospace, aluminium extrusions are also employed in manufacturing missiles, rockets, and satellites. Furthermore, aluminium extrusions serve diverse purposes in the automotive, electrical, and construction industries. Aluminium stands out as an incredibly versatile material for extrusion, with its potential applications bounded only by one's creativity.

These extrusions are also instrumental in fabricating flight control surfaces, encompassing ailerons, elevators, and rudders, vital for manoeuvrability and stability during flight. Moreover, they are indispensable in assembling landing gear systems and other essential structural components.

In summary, aluminium aerospace extrusions are pivotal in the aviation industry, creating diverse aircraft parts and ensuring optimal performance and safety in aerospace applications.

The following are some typical applications for aluminium aerospace extrusions:

Aircraft skins: Aircraft skins, also known as aircraft skin materials or aircraft skin panels, are an essential component of an aircraft's structure. They form the outermost surface of the aircraft and serve several critical functions.

Aircraft frames: Aircraft frames are often a part of the overall structure of an aircraft. The structures refer to the framework or skeleton that supports the entire plane and its components. These structures are designed to withstand the forces and loads experienced during flight, including aerodynamic and gravitational forces.

Fuel tanks: The fuel tank is an essential component of every aircraft. Aircraft fuel tanks come in various designs to accommodate various aircraft types. The three most popular fuel storage options are integral, bladder, and rigid removable fuel tanks.

Hydraulic reservoirs: Most aircraft systems necessitate hydraulic fluid reservoirs, which serve the dual purpose of supplying hydraulic pumps with readily available fluid and accommodating fluid volume fluctuations.

Landing gear struts: A commonly employed shock-absorption mechanism for aircraft landing gear, known as the strut, utilizes a combination of pneumatic and hydraulic systems. This configuration effectively mitigates the jolts experienced during landing while dampening vertical oscillations.

Wing spars: Wing spars serve as the foundational framework for aircraft wings, akin to their skeletal structure. The fuselage is securely attached to these spars to provide stability and support. During airframe and fuselage inspections, the condition of the spars is thoroughly examined to assess the wing's structural integrity.

The benefits of using aluminium aerospace extrusions:

- Aluminium extrusions possess both strength and lightweight nature, rendering them exceptionally suitable for applications in the construction of aircraft and spacecraft. Additionally, they exhibit corrosion resistance, ensuring their durability and longevity compared to alternative materials that may deteriorate over time.

- Aluminium's exceptional thermal conductivity makes it a prime choice for applications requiring efficient heat dissipation, particularly when heat-sensitive components like electronics need effective cooling.

- Aluminium extrusions offer cost-effective solutions for a wide range of applications due to their corrosion resistance and extended lifespan.

- Aluminium extrusions are sustainable and recyclable, making them eco-conscious for any project.

- Extruded aluminium is also easy to machine and fabricate, making it versatile in different industries.

Conclusion

Furthermore, ongoing research and development efforts are continually pushing the boundaries of what is achievable with aluminium aerospace extrusions, promising even more advanced materials and designs in the future.

In essence, aluminium aerospace extrusions are integral to the aviation industry's past, present, and future. They epitomize the spirit of progress and innovation that characterizes aerospace engineering. Their continued evolution will undoubtedly contribute to safer, more efficient, and more environmentally sustainable air travel for generations to come.

This news is also available on our App 'AlCircle News' Android | iOS

.gif/0/0)

.jpg/0/0)