Alumina or aluminium oxide (Al2O3), the key raw material for producing aluminium is a white powder extracted from bauxite through Bayer process. Due to the exponential growth of the aluminium industry in last two decades and the significance of alumina in the upstream value chain, aluminium producers are building their own refineries and expanding the existing facilities to secure the availability of this resource.

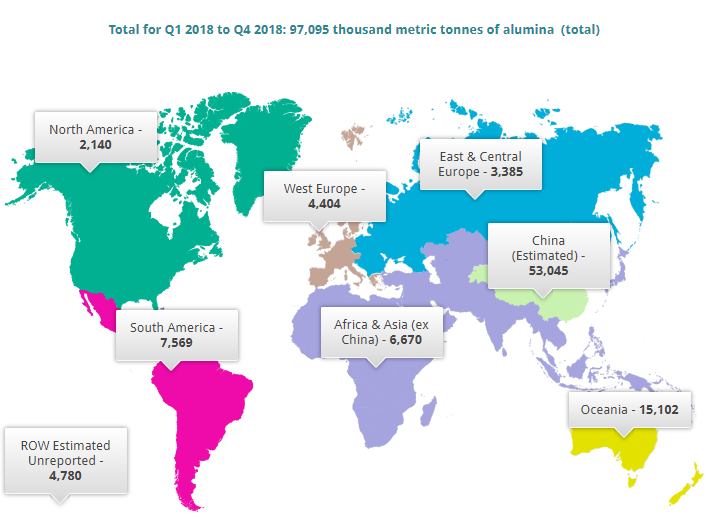

Driven by a growing demand for aluminium in China, followed by Middle East and India, bauxite production and alumina refining capacity has increased immensely across the major alumina producing regions of the world. The below map from International Aluminium Institute shows YTD alumina production in the world in 2018:

{alcircleadd}

Alumina is supplied to the world aluminium smelters from refineries operated by big names like Rio Tinto, Rusal, Norsk Hydro, Alcoa, South 32, Chalco, Xinfa, China Hongqiao and Nalco in India. We are listing below the top five single site alumina refineries based on capacity and production. We are also touching up the key refineries that are not in the top five but have significant capacity. Read through to get an overview:

Norsk Hydro Alunorte Alumina Refinery

Hydro Alunorte is the world's largest alumina refinery and is located in Pará, Brazil, in the industrial park of Barcarena.

Since its commissioning in 1995, the refinery has undergone three expansions that increased its production capacity, all of which were implemented without any production downtime. Nominal capacity of the alumina refinery stands at 6.2 million tonne. The company supplies the domestic and international markets. On average, 14% of its production goes to the domestic market and the other 86 % goes for export. Currently, Hydro Alunorte exports its products to ten countries in the Middle East, North America and Europe. Hydro holds 92.1 per cent of Alunorte ownership. The refinery is fed by bauxite from Hydro’s Paragominas bauxite mine.

Following orders from federal, state and local authorities in Brazil on the issue of bauxite residue pond leakage from its DRS2 bauxite residue deposit, Hydro had to close its DRS2 bauxite residue deposit in March and cut the alumina production capacity by 50%. Since then, the refinery is running at fifty per cent capacity. Norsk Hydro is striving to convince Brazilian authorities to allow it to resume full production at Alunorte refinery. According to the latest update, Brazilian expert study showed that there was no overflow from Alunorte’s residue deposit areas DRS1 and DRS2 in February 2018. The study also concludes that Alunorte, from a water management perspective, can produce at its nominal capacity of 6.3 million tonnes of alumina a year. The refinery is expected to start full production by the second quarter of 2019.

The company generates more than 4,400 direct and indirect jobs, mostly for citizens of Pará.

South 32 Worsley Alumina Refinery

The Worsley Alumina Refinery history goes back to the early 1960s when a group of local entrepreneurs formed a firm to explore, develop and sell deposits of bauxite ore on the eastern side of the Darling Range, near Boddington. Construction of a mine site and refinery began in 1980 and the first alumina was produced in April 1984. Currently, Worsley Alumina is owned by is a joint-venture partnership between South32 (86%), Japan Alumina Associates (Australia) (10%) and Sojitz Alumina (4%).

As part of the Worsley Alumina operations, bauxite is mined near the town of Boddington, 130 kilometres (kms) south east of Perth and then transported for more than 50 kms to the Worsley alumina refinery. The alumina is shipped to smelters around the world, including South 32’s Hillside and Mozal aluminium smelters in Africa.

Over the past three decades the refinery’s production has increased four-fold, making Worsley Alumina the second largest and lowest-cost alumina producers in the world with an annual capacity of 4.6 million tonne. This is one of the highest revenue generating operations of South 32, which is a spin off from BHP Billiton.

Alcoa Pinjarra Alumina Refinery

Pinjarra alumina refinery at Pinjarra, Western Australia was commissioned in 1972 and as one of the world’s largest refineries, has an annual production capacity of 4.2 million tonnes. It is owned by Alcoa World Alumina and Chemicals (AWAC), the joint venture between Alumina Limited and Alcoa Inc. Alumina Limited owns 40 per cent of AWAC and Alcoa owns the remaining 60%. The refinery is fed from bauxite from the Huntly bauxite mine.

Since an efficiency upgrade in 2007, the refinery delivers a substantial reduction in energy intensity per tonne of alumina produced, as well as improvements in the use of natural resources. Approximately 1,000 employees and 250 contractors work at the refinery, with an estimated 60 per cent of employees being from local communities. In 2017, Alcoa of Australia’s operations in Western Australia and Victoria injected approximately AU$400 million into Australia’s federal, state, and local governments through the payments of taxes, royalties, rates, and charges. Alcoa’s Australian operations represent one of the world’s largest integrated bauxite mining, alumina refining and aluminium smelting systems. Alcoa Pinjarra Alumina Refinery along with Kwinana and Wagerup produce almost 45 per cent of Australia’s alumina.

Queensland Alumina Limited (QAL)

Queensland Alumina Limited (QAL) was commissioned in 1967 with an annual capacity of 3,950,000 tonnes of alumina. The refinery covers 80 hectares of a 3,050 hectare in the city of Gladstone. Adjacent to the refinery is a wharf and storage facility on South Trees Island, which is connected to the mainland by a causeway bridge. QAL is owned by two shareholders, Rio Tinto Aluminium (80 per cent) and Rusal (20 per cent).

QAL’s bauxite supplies are mined in Weipa in far north Queensland and shipped around Cape York and 2,000 kilometres down to QAL in Gladstone. Queensland Alumina Limited (QAL) is one of the largest alumina refineries in Australia. One of the world's best smelter grade alumina is used locally by Boyne Smelters Limited and shipped across the globe.

São Luís Alumar Alumina Refinery

Alumar, located in Maranhão state outside São Luis, north-east Brazil, is jointly owned by Alcoa Aluminio and Alcoa World Alumina and Chemicals/AWAC (54 per cent), South32 (36 per cent) and Rio Tinto Alcan (10 per cent). Alcoa manages the facility. The refinery was inaugurated in 1984 and has been an important economic driver in the region ever since.

It is another large alumina refinery in South America and the vast majority of its employees are hired locally. The refinery has a capacity of 3,639,000 tonnes of alumina per year. The last capacity expansion in 2011 more than doubled the capacity of the refinery from 1.5 million tonnes per year to 3.6 million tpy. Alcoa’s share of the expansion stands at 1.1 million tpy. The expansion placed the Alumar alumina refinery as one of the lowest cost refineries in the world. The AWAC share of the Alumar refinery expansion is supplied by bauxite from AWAC Juruti bauxite mine.

Yarwun Refinery at Queensland, Australia, owned by Rio Tinto Alcan comes at a very close sixth position with a capacity of 3.4 million tonnes.

The Yarwun alumina refinery is located in Gladstone in central Queensland. Construction began in 2002 and the first shipment of alumina was made in late 2004. Bauxite is transported from Rio Tinto Aluminium’s mining operations in Weipa on Western Cape York to Yarwun refinery for refining. Recent expansions have more than doubled production at the Yarwun refinery to 3.4 million tonnes of alumina per year. Yarwun's alumina is shipped to customers in Australia and overseas, including the Middle East.

NALCO’s Damanjodi refinery in Odisha, India has a capacity of 2.2 million tonnes. The refinery not only feeds its aluminium smelter but the company generates significant revenue by exporting alumina globally.

Wagerup refinery and Kwinana refinery in Western Australia; owned and operated by Alcoa World Alumina and Chemicals have respective capacities of 2.4 and 2.1 million tonnes.

Emirate Global Aluminium’s (EGA) under construction Al Taweelah alumina refinery will be the first alumina refinery in the UAE and the second in the Middle East. EGA has announced the completion of commissioning process of the calcination section of its alumina refinery at Al Taweelah in Abu Dhabi. EGA is also developing a bauxite mine and associated export facilities in the Republic of Guinea in West Africa to feed the refinery. Once complete, the refinery will produce 2 million tonnes of alumina per year and meet 40 per cent of EGA’s alumina requirements. The refinery is expected to produce its first batch of alumina by H1 2019.

Chalco’s total alumina production capacity stood at 16.86 million tonnes at end-2017, according to its annual report. Weiqiao refinery, a subsidiary of China Hongqiao Group is claimed to be China's largest alumina refinery. Since the total operating capacity of the individual refineries is not documented by the owner companies, our listing does not include the China alumina refineries.

Responses