The global aluminium die casting machinery market is projected to grow at a CAGR of 7 per cent during the period 2016-2020. The aluminium die casting machinery is used to produce cast aluminium parts for applications in various end-user sectors which include automotive, aerospace and defence, marine, and many more.

The high pressure die casting segment was dominated the aluminium die casting machinery market in 2015. The segment accounted for about 70 per cent of the total market share.

{alcircleadd}

Aluminium is the most widely used die casting alloy and finds place in every type of application because of mechanical properties. The aluminium castings are lightweight and can withstand the highest operating temperatures among all die cast alloys.

A rise in preference for light-weight automobiles is augmenting the need of aluminium die cast components. This is leading to a potential demand for aluminium die cast machinery.

The companies involved in manufacturing and supplying of wide array of aluminium die casting machine are investing huge amount in developing new technologies and in manufacturing facilities to stay cost-effective and competitive. Following are the top five aluminium die casting machinery manufacturers in the world. The list is based on current market report of aluminium die casting machinery available through open source.

Bühler, based in Uzwil, Switzerland, is a technology partner in the supply of die casting solutions worldwide. The company is at the cutting edge of die casting technology in terms of quality, performance, and process expertise. Bühler Group operates in over 140 countries around the world. The company generated sales revenues of CHF 2,45 billion in fiscal 2016

The company’s Carat system is a two-platen die casting machine. It is available in 13 sizes with a locking force from 10,500 to 44,000 kN. The Carat system is the best solution for customers that manufacture large and complex parts that have to meet the highest requirements for quality, it claims. At present, over 400 systems have been sold on five continents – more than 120 have been installed in China and another 30 are already ordered by Chinese customers.

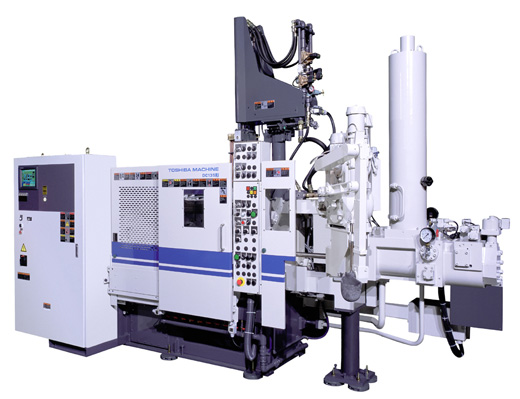

Toshiba Machine, headquartered in Japan, is the manufacturer of die casting machines. The company manufactured a total number of 10000 sets of die casting machines since it produced the first one back in 1953.

The company produces and sells three models from 135 tons to 350 tons of die-cast machine DC-J series for aluminium and zinc forming. Its CS Series is used in production of large sized die castings such as automobile parts.

Also Read: Allison acquires aluminium transmission castings supplier

Dynacast is a global manufacturer and supplier of the highest quality precision metal components. The company provides solution to industries including automotive, consumer electronics, and healthcare.

{googleAdsense}

Dynacast’s high-end technology solutions such as Multi-Slide Die Casting, Cold Chamber Die Casting, Metal Injection Molding (MIM), and interactive Process & Metal Selector allow OEMs create complex designs that are unique and non-replicable.

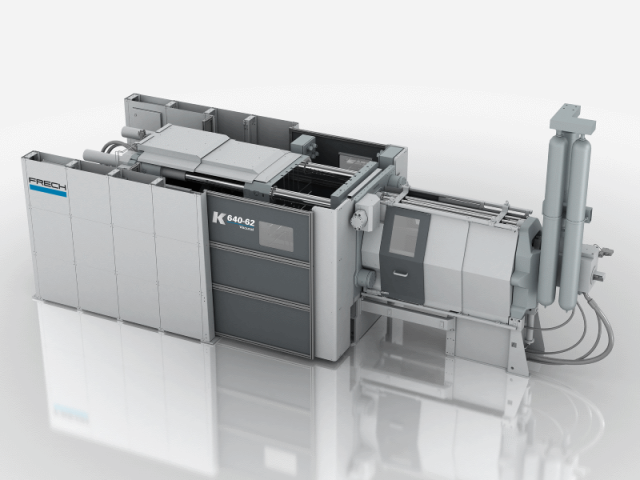

Oskar Frech GmbH + Co. KG is the manufacturer and supplier of the highest quality die casting machines. The Frech Group has it’s headquarter in Schorndorf, Southern Germany. The company provides hot and cold chamber die casting machines for aluminium, magnesium and zinc alloys.

The cold-chamber die casting machines comes with locking forces from 2,750 kN to 44,000 kN for the production of a wide range of castings, from small OEM parts to engine blocks or gearbox housings, as well as chassis and body components made of aluminium and magnesium alloys.

Idra Group, based in Italy, provides die casting machines and complete cells from 250 to 5000 tons, for aluminium and magnesium. The company is a specialist in the field of die casting machines and fully automated die casting cells.

Idra Group’s OLS die casting machines represents the state of the art for its technology. OLS series cold chamber machines, ranging from 420 tons to 4000 tons of clamping force, are designed for better performance and constant product quality.

Riccardo Ferrario, General Manager of Idra Group said, “Our mission is and will be the design and manufacture of die casting presses and automated cells for the light alloy foundry business worldwide”

Responses