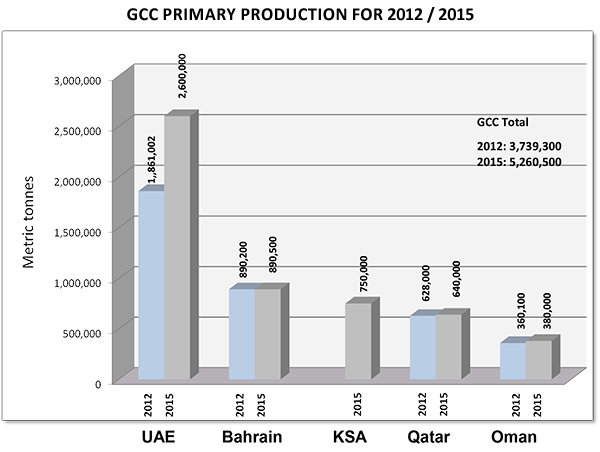

After China, another region that is growing substantially in primary aluminium production is the GCC (Gulf Corporation Council) or the Gulf countries. The volume of aluminium production in the Gulf region stood at 5.2 million tonnes in 2015, accounting for around 10 per cent of total global output of 58 million tonnes. This is due to the major expansion of existing smelters and commissioning of new projects that primary aluminium production is increasing at a faster rate in the GCC countries. After oil and natural gas, now aluminium is one of the key economic drivers for the Gulf region. Gulf countries are constantly working towards making a shift towards non-oil sector especially the aluminium industry which gets the benefit of cheap energy and abundance of manpower and high technology.

Five major aluminium smelters contribute to produces about 5.2 million tons of primary aluminium in the GCC region. Forty per cent of the total aluminium production is utilised by the domestic downstream aluminium industries and about 60 per cent is exported to different parts of the world.

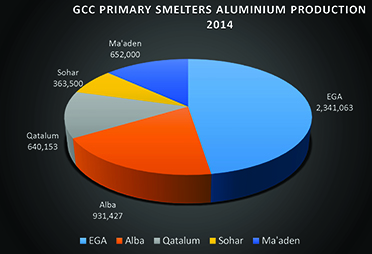

The top five smelters in GCC are:

1. Emirates Global Aluminium(EGA) which is a collaboration of (Dubal - Dubai Aluminium and Emal - Emirates Aluminium, United Arab Emirates

2. Alba - Aluminium Bahrain, Bahrain

3. Qatalum - Qatar Aluminium, Qatar

4. Sohar aluminium, Oman

5. Maa’den Aluminium, Saudi Arabia

1. Emirates Global Aluminium or EGA: Dubal - Dubai Aluminium and Emal - Emirates Aluminium, United Arab Emirates

Emirates Global Aluminium (EGA) in UAE is the top primary aluminium producer in GCC and it is also among the five largest aluminium producers in the world. EGA’s consists of Dubai Aluminium (“DUBAL”) and Emirates Aluminium (“EMAL”) – whose combined production is 2.4 million tpy.

DUBAL’s Jebel Ali operation comprises a 1 million tpa smelter, a 2,350 MW power station and other facilities. Commissioned in 1979, DUBAL celebrated its 35th anniversary in 2014. EMAL’s Al Taweelah operation comprises a 1.3 million tpa smelter, a 3,100 MW power station and other facilities – is the world’s largest single-site primary aluminium producer. Commissioned in 2009, EMAL celebrated its 5th anniversary in 2014.

.jpg)

EGA’s primary product range includes Standard, sow and T ingots, foundry ingots and also liquid metal with mominal 99.70 per cent aluminium content. To support the initiative to encourage downstream aluminium industries in the Khalifa Industrial Zone Abu Dhabi (“KIZAD”) EMAL has developed a Liquid Metal Transfer facility to transfer liquid aluminium to customers efficiently and safely.

2. Alba - Aluminium Bahrain, Bahrain

Bahrain is a small island country which has changed the economy over the years by slowly shifting to aluminium. Aluminium Bahrain (ALBA) is one of the largest aluminium smelters in the world known for its technological strength and high quality aluminium and solely account for the aluminium production in Bahrain. Alba began operations in 1971 with annual capacity of just 120,000 mtpa as the first aluminium smelter in the Middle East, and the first non-oil industry established in Bahrain.

According to their annual report for FY 2015, Alba’s production topped 960,643 metric tonnes (mt), up by 3.1% YoY, while total sales volume rose by 2.2% YoY to reach 951,944 mt. The company reported total sales of BD 766.7 million (US$ 2.039 billion) in 2015. For the period from January to September 2016, the Company sales volume stretched to 717,569 mt, up from 699,362 (mt) in the same period of 2015 while production volume increased by 3,722 mt to reach 720,750 mt YTD.

{googleAdsense}

The product range of Alba includes Standard Ingots, T ingots, rolling slabs, foundry alloy ingots, extrusion billets etc. for supplying to domestic and international downstream sector. Alba also produces high purity aluminium with 99.7 per cent aluminium content. The metal, at these purity levels or higher, is supplied in liquid form to downstream industries in Bahrain whose premises are located close to the smelter.

3. Maa’den Aluminium, Saudi Arabia

Saudi Arabia houses Ma’aden Aluminium (MA), a joint venture between the Saudi Arabian Mining Company (Ma’aden) and Alcoa that started operations in 2014. The US$10.8b project is expected to be the largest and most efficient integrated aluminium complex in the world once it is completed.

MA’s facilities include a bauxite mine, an alumina refinery, aluminium smelter, can sheet rolling mill and an automotive mill.

The company’s Al Ba’itha mine, the first bauxite mine in the Middle East, will produce over 4 million metric tonnes of bauxite annually. The bauxite ore will be refined in the GCC's first alumina refinery to produce 1.8 million mtpy of alumina, much of which will be processed in the smelter to produce the current capacity of 740,000 mtpy of primary aluminium.

4. Sohar aluminium, Oman

Sohar Aluminium was formed in September 2004 to undertake a landmark Greenfield aluminium smelter project in the Sultanate of Oman and is jointly owned by Oman Oil Company, Abu Dhabi National Energy Company PJSC - TAQA and Rio Tinto Alcan. By implementing decades of industry insight in its design, specification and construction Sohar Aluminium has been created to ensure efficiency, environmental protection and the utmost safety of its workforce. The smelter has an annual production capacity of 375,000 tonnes of high quality Aluminium.

Sohar Aluminium’s primary smelter produces metal in three forms:

1. Ingots - 23.7kg

2. Sows - 700kg

3. Hot Metal - available to local downstream partners to reduce energy consumption in subsequent processing.

5. Qatalum - Qatar Aluminium, Qatar

Qatalum is a JV between Qatar Petroleum and Hydro Aluminium of Norway and produces about 640,000 tons of high-quality primary aluminium products per annum. Qatalum’s complex facilities include a carbon plant, port and storage facilities, as well as a captive power plant.

Qatalum’s state-of-the-art cast house products are value-added extrusion ingots and foundry alloys that meet the stringent quality standards of its global customer base. Used in a variety of industries including the automotive, construction, engineering and in the manufacturing of consumer goods, by the end of its journey, Qatalum’s aluminium reaches the entire global community.

Responses