Researchers from Ateneo de Manila University and the Nara Institute of Science and Technology have developed a groundbreaking, low-cost method to transform ordinary aluminium into a transparent, glass-like material with remarkable durability. By using microdrops of acid and just two volts of electricity, they produce transparent aluminium oxide (TAlOx) without relying on expensive equipment or harmful processes.

A cost-effective, low-impact approach

This innovation paves the way for sustainable applications across industries, including touch screens, solar panels, protective coatings, and miniaturised electronic devices, potentially reshaping modern technology with a more accessible, eco-friendly material.

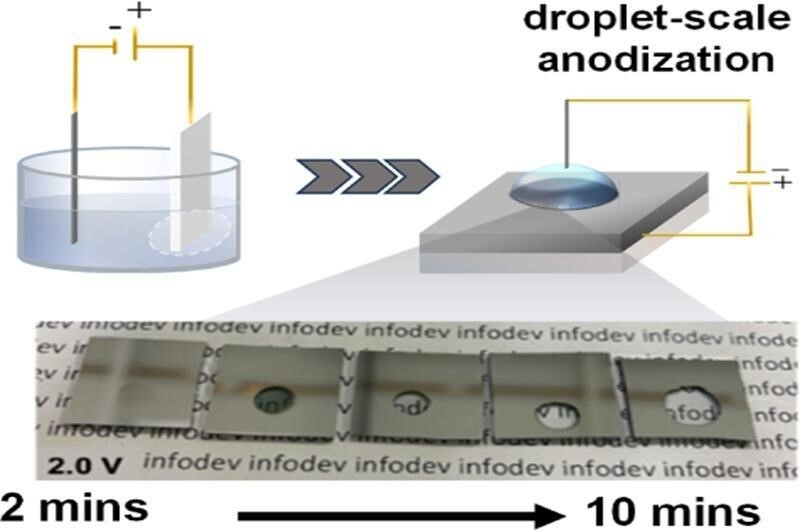

The innovative method relies on "droplet-scale anodising," a process that uses tiny acid droplets to transform the aluminium surface. This technique harnesses the electrowetting effect, where an electric field changes the droplets' behaviour on the metal, enabling precise and uniform oxidation.

This approach is simpler and far more cost-effective than conventional methods that require high-power lasers, vacuum chambers, or large quantities of corrosive acids. Droplet-scale anodising significantly lowers production costs and minimises environmental impact by using just two volts of electricity — less than the power of an AA battery.

This breakthrough not only makes transparent aluminium more accessible but also proves that cutting-edge materials can be created with straightforward, affordable technologies, challenging the notion that innovation in this field is limited to high-tech laboratories.

Transparent aluminium oxide (TAlOx)

Transparent aluminium oxide (TAlOx) boasts exceptional properties, making it a strong contender against glass and other transparent materials. Its superior strength makes it perfect for applications where durability is critical. The new production method enhances sustainability by reducing energy consumption and minimising the use of hazardous chemicals. Compared to traditional transparent materials used in electronics and coatings, TAlOx offers a rare combination of clarity, strength, and ease of fabrication. Another key advantage is its compatibility with large-scale manufacturing. As production techniques evolve, TAlOx could become a practical alternative for the technology and construction industries, where the need for robust, efficient materials continues to grow.

Potential use of TAlOx in multiple industries

The emergence of transparent aluminium holds the potential to revolutionise multiple industries. Its unique blend of transparency, lightweight properties, and exceptional strength makes it an ideal material for applications across technology, energy, and construction. Some of its most promising uses include:

The discovery of a cost-effective process for producing transparent aluminium signals the start of a new era in functional materials. The blend of affordability and high-performance positions TAlOx as a potential standard across various industries in the near future. The next step for researchers is to scale up production and refine the material's optical and mechanical properties. Commercial applications could become a reality sooner than expected with growing interest and investment from companies and institutions.

Responses