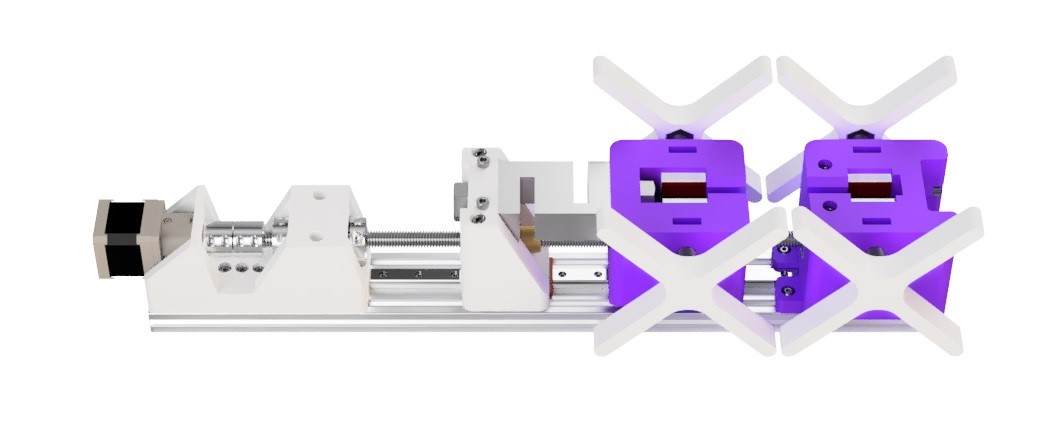

Material testing is critical in large industries, as producers must be able to rely on the qualities of the raw materials they use. The Universal Tensile Testing Machine is one of the best examples of this. The test fixture is made of 3D-printed components and is constructed on top of an aluminium extrusion. For the construction of the frame of the machine, 550mm 2060 European Standard Aluminum Extrusion has been used.

The machine was displayed by a student named Xieshi Zhang at the Hackaday.io, one of the world’s largest collaborative hardware development communities. Tensile testing machines are special versions of universal testing machines used to test the tensile strength of materials. It applies a tensile force to a specimen (stretches it) until it breaks, then quantifies the forces involved. Although this machine was designed primarily for tensile testing, this variant can also do compression tests.

{alcircleadd}

Unlike a six-figure industrial machine, this project is significantly cheaper, costing only $300 to construct. It reads a tensile strain gauge using an Arduino and can administer up to a kilonewton of force. It operates a lead screw with a NEMA 17 stepper motor to provide tensile strain or compression to the specimen under test.

The tensile testing system's primary components are the fixed fixture, moving fixture, load cell (and its mount), and motor (a geared NEMA 17 stepper motor). The motor controls the moving fixture through a lead screw linked to a load cell. The motor moves the lead screw once the specimen has been loaded and the tensile test has commenced.

The lead screw converts rotations into linear motion, which pulls back the load cell, but the specimen resists the pulling force by producing an equal and opposite response, which is then recorded by the load cell. This procedure is repeated until the specimen cracks. Compression tests follow the same process, only the specimens are loaded in the other direction.

Responses