Volkswagen Group's Slovakia site is one of the first units to enrol in the Aluminium Closed Loop project, which includes recycling aluminium stamping offcuts from press shops that come back to the aluminium roll suppliers. These aluminium offcuts are then subjected to reform, after which the actual metal can be extracted for re-production without any stain on the quality. Moreover, using secondary aluminium is cost-effective and saves almost 95 per cent of energy than the production of primary aluminium from bauxite. The Bratislava plant in Slovakia is the creator of Audi Q7 and Q8 body parts with the help high-pressure hydraulic press. This sustainable technique with which the company manages carbon emissions is extraordinary, and this planned loop is an example of a better future with no environmental traumas.

Volkswagen, as a group and individually on their Slovakia Branch, has moved one step closer to achieving its sustainability goals under the provisions of the Zero Impact Factory strategy aiming at climate neutrality. To make this dream come true, the company extensively participates in projects and also incorporates high-end technologies in its processes to leave a mark on the environment.

One of these projects is 'Aluminium Closed Loop', which was announced at Audi's Neckarsulm site in 2017. The project is currently operational at specific units of the Group that have press plants to produce high-precision aluminium parts. The sites are Audi in Neckarsulm, Audi Hungaria in Győr, Audi in Ingolstadt and Volkswagen Slovakia in Bratislava.

In 2021, the Aluminium Closed Loop project had successfully decimated more than 195,000 tonnes of carbon dioxide through the production process of just Audi models. Since its inception in 2017, it has saved almost 725,000 tonnes of Co2.

The Bratislava site of Volkswagen had enlisted itself under the Group's Aluminium Closed Loop project, technically one year back, in July 2021. Many SUV car components are currently manufactured in Bratislava, including the Volkswagen Touareg, Audi Q7, Audi Q8, Porsche Cayenne and Porsche Cayenne Coupé. They manufacture exterior skin parts, add-on parts, roofs, hoods and tailgates, doors, windows, window frames and many more items. The Aluminium Closed Loop is a beneficial programme that helps in closed loop waste recycling, which avoids the energy-intensive production scheme of primary aluminium.

The Head of the Environmental Department at Volkswagen Slovakia, Michaela Hletková Ploszeková, commented: "The high energy demand can be minimized, among other things, by using recycled materials, thereby contributing to a better environmental balance of our vehicle projects even before our vehicle production begins."

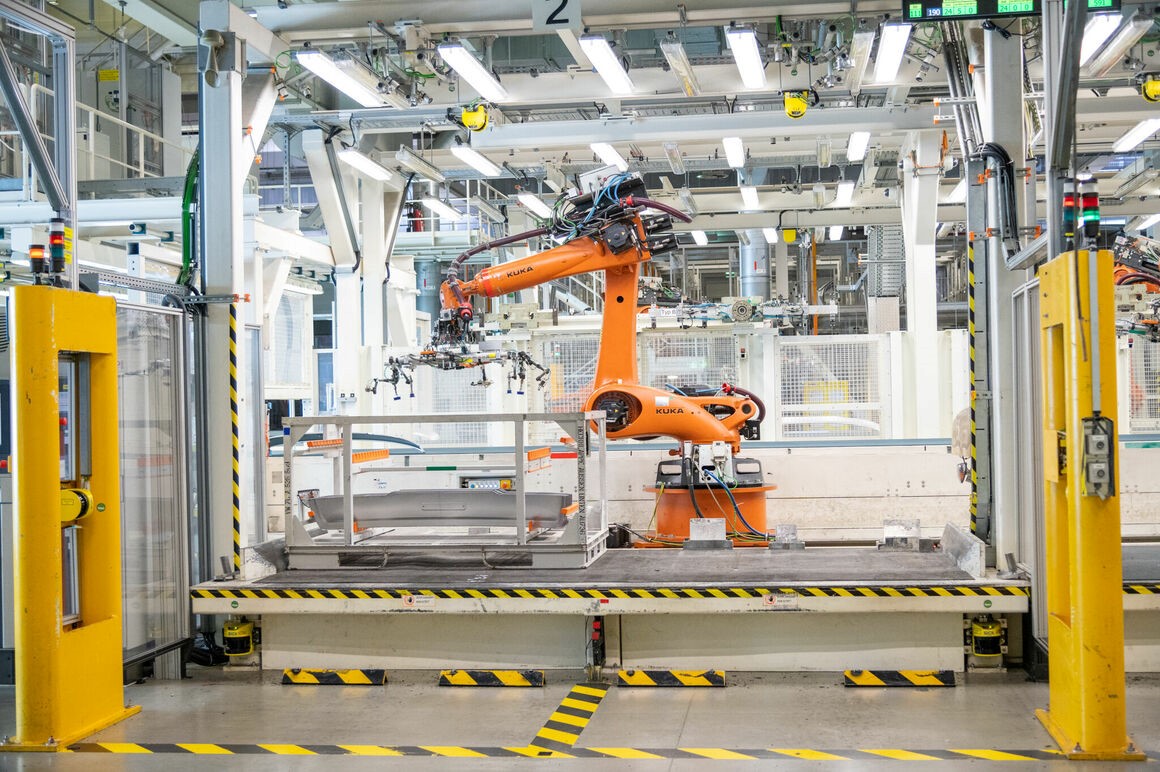

The car body components are comprised of aluminium and steel sheets that are retrieved from aluminium rolls, also known as coils, at Audi's Hungarian sister plant in Gyor, before being put under pressing tools at the Bratislava press shop. The aluminium is sorted from the auxiliary stamping wastes generated at the facility and shipped for reuse.

The Head of the Press Shop Specialist Team, Stanislav Novák, exclaimed: "Thanks to the separation and cleaning processes in the production process as well as at the recycler, the stamping waste from the press shop for recycling in the Aluminium Closed Loop achieves a purity level of 99.9 per cent. In the pilot year, the company delivered more than 6,600 tons of aluminium offcuts to the Aluminium Closed Loop project despite fluctuating production due to the difficult global situation. We want to continue to increase this share gradually."

Recently, the aluminium scrap is being traded by a logistic company from the press shop with the help of trucks. In the upcoming year, the ploy is to utilize eco-friendly vehicles for this material transfer. With an evolved system, the waste can be transported directly from Slovakia to the Group's Aluminium smelter to be transferred back to the Bratislava press shop as processed secondary aluminium or aluminium sheets with the original quality. Here the aluminium would be again put under shaper and machinery to be constituted into the body parts for SUVs.

Audi knows that it is impossible to contain all of the carbon emissions a product can emit in its life cycle. Yet the company has invested in offsetting projects worldwide to check the otherwise unavoidable carbon emissions that Audi is responsible for during the production of its vehicles. An automobile's emissions from its inception and during its lifetime cannot always be accounted for.

Responses