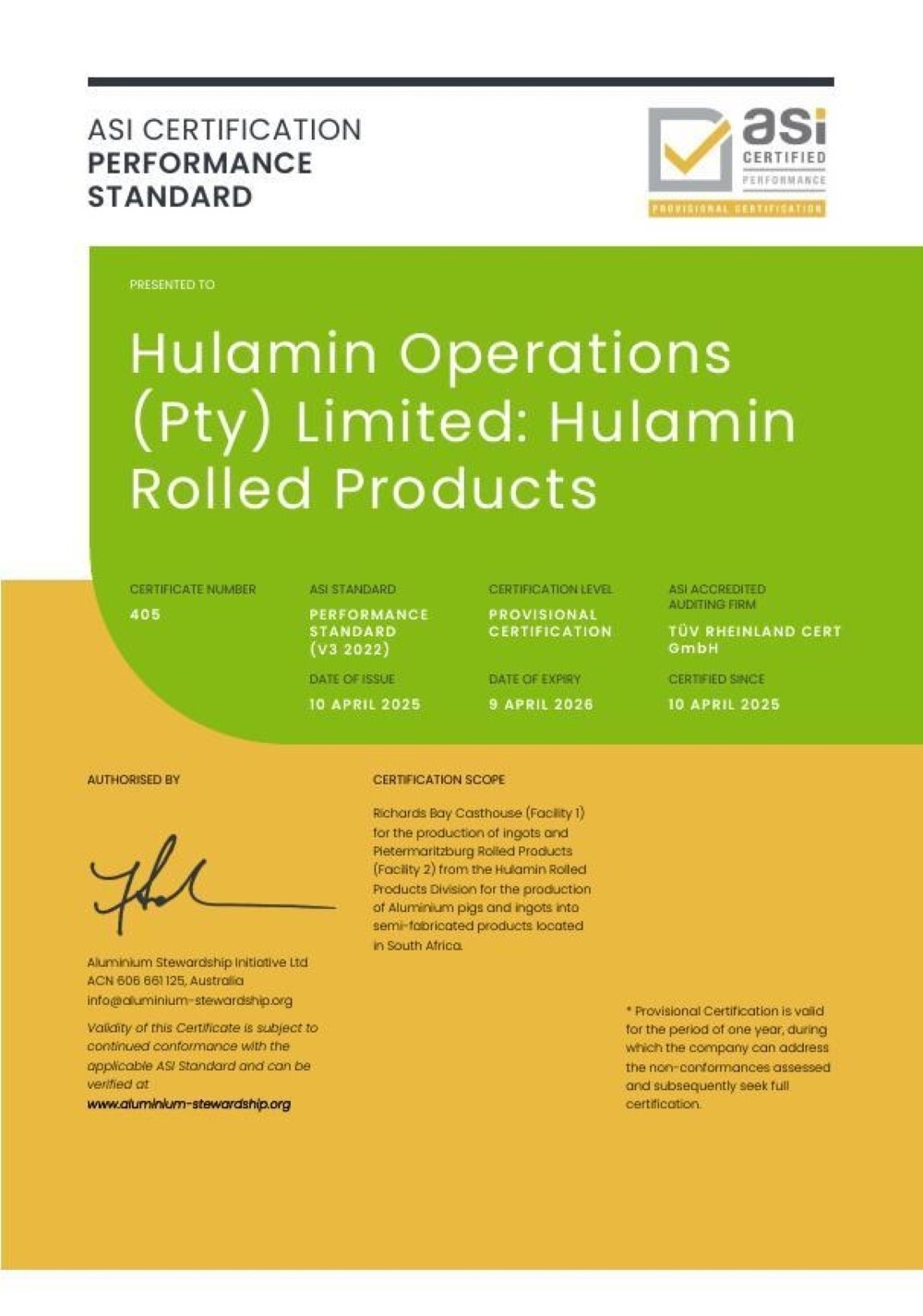

Hulamin Operations (Pty) Limited has achieved ASI Performance Standard V3 (2022) with Provisional status for their facilities in South Africa. This includes the Richards Bay Casthouse (Facility 1) part of the Hulamin Rolled Products Division for the production of ingots, and the Pietermaritzburg Rolled Products facility (Facility 2) for the conversion of aluminium pigs and ingots into semi-fabricated products.

Aluminium Stewardship Initiative (ASI) today announced that Hulamin Operations (Pty) Limited: Hulamin Rolled Products has been certified against the ASI Performance Standard V3 with Provisional status. The certified operations include a casthouse in Richards Bay and re-melting and recycling facilities, direct-chill ingot casting, hot rolling, cold rolling, foil rolling mills, and finishing processing lines in Pietermaritzburg. The facilities specialise in converting primary aluminium into semi-fabricated products, serving sectors such as packaging, engineering, automotive, and construction, with an annual production capacity of approximately 200,000 tonnes.

The ASI Certification program was developed through an extensive multi-stakeholder consultation process and is the only comprehensive voluntary sustainability standard initiative for the aluminium value chain. The ASI Performance Standard V3 and ASI CoC Standard V2 were launched in May 2022 following a multi-year revision process. The ASI Performance Standard V3 defines 11 principles and 62 criteria under three sustainability pillars – Environment, Social, and Governance – with the aim to address pressing sustainability issues in the aluminium value chain, such as biodiversity, Indigenous Peoples rights, circularity, and greenhouse gas emissions.

The Provisional Certification serves as a strategic and flexible approach for aluminium sector actors to gain access to ASI’s sustainability standards framework, learn, and improve their practices over a defined period. It provides an opportunity for members to commence their ASI Certification journey while requiring a commitment to move towards full certification as soon as possible.

The independent, third-party audit of Hulamin Rolled Products was carried out by TÜV Rheinland Cert GmbH. A full listing of audit findings is available in the summary audit reports, linked below. Three minor non-conformances were noted under Criteria 5.3a-e GHG Emissions Reduction Plans, 9.8a Conflict-Affected and High-Risk Areas – Strong Management Systems and 9.8e Conflict-Affected and High-Risk Areas – Report annually. One major non-conformance was identified under Criterion 11.1a Occupational Health and Safety (OH&S) Management System, resulting in a Certification with Provisional status of one year. Hulamin Rolled Products will be implementing corrective actions, to be verified in a follow-up audit. TÜV Rheinland Cert GmbH approved the corrective action plans for the Major non-conformances prior to submission of the audit report to ASI.

Note: This article has been issued by ASI and has been published by AL Circle with its original information without any modifications or edits.

Responses