OTTO JUNKER, a leading supplier of high-quality melting and heat treatment plants, presents two pioneering products which will help shape the future of metal processing: EcoJet, the latest product on the market, and JuDy, a proven solution which, together with EcoJet, will be an unbeatable combination. These future-oriented solutions allow a highly efficient preheating of bars and billets and environmentally friendly heating without using fossil fuels while at the same time minimising costs. With these furnace solutions, OTTO JUNKER offers a sustainable and cost-efficient alternative for the industry.

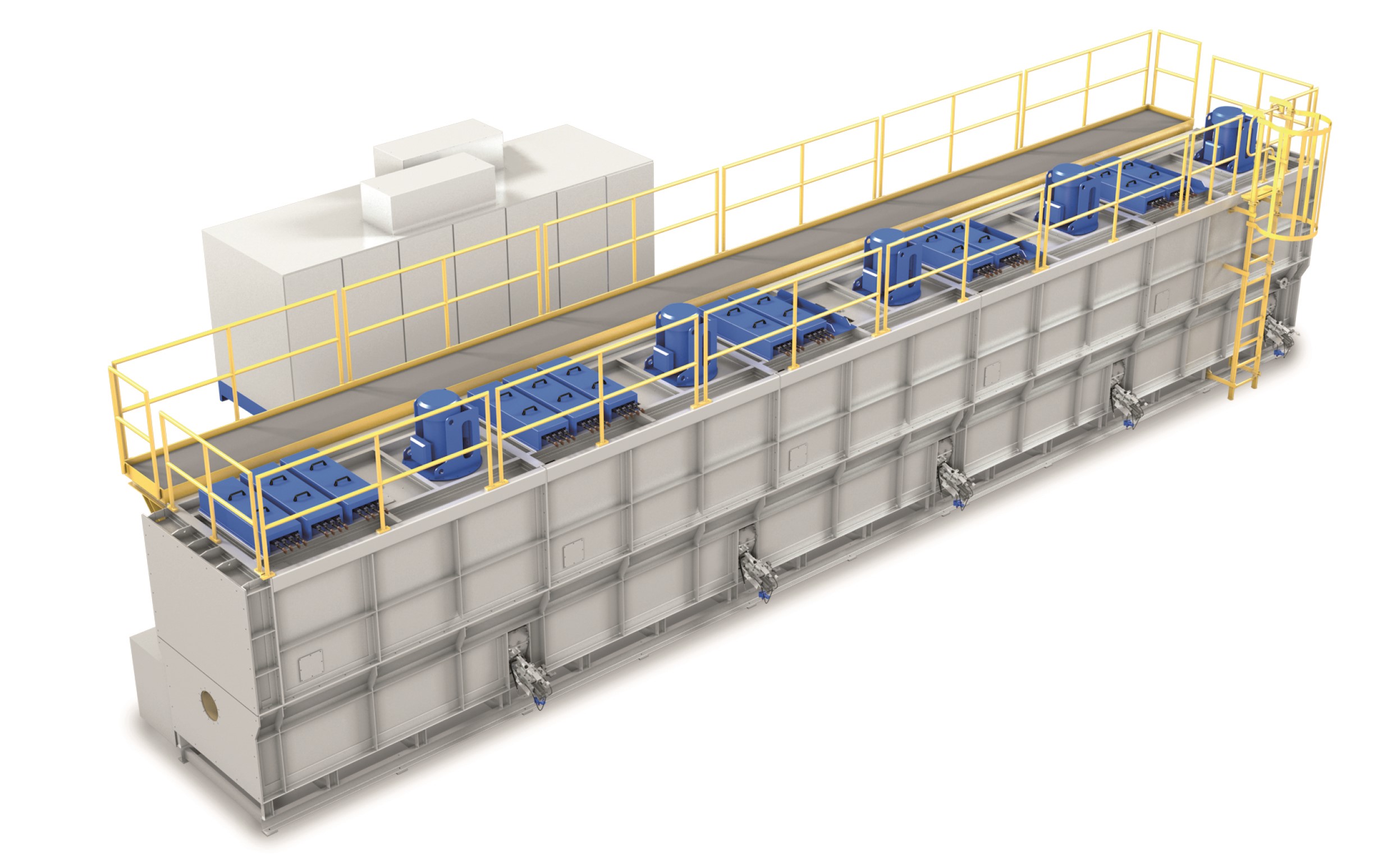

Sustainable preheating with EcoJet

EcoJet is a preheater which combines maximum efficiency and environmental protection. With an efficiency of more than 95 per cent, EcoJet sets new standards in the emission-free preheating of bars and billets. Thanks to decades of experience in resistance and convection heating and by using state-of-the-art technologies, including cutting-edge flow simulation and calculations, OTTO JUNKER can offer specially designed heater banks with a high-power density for a wide range of applications. Temperature monitoring is by means of thermocouples in order to ensure optimum heat transfer. All the components of the EcoJet preheater result from in-house developments, engineering, and manufacture, guaranteeing maximum quality and reliability.

By using the EcoJet preheater, companies can improve their ecological footprint and ensure their productivity in fluctuating gas supplies. With rapid heat-up times and precise temperature control, the furnace offers a sustainable solution combining environmental protection and economic efficiency.

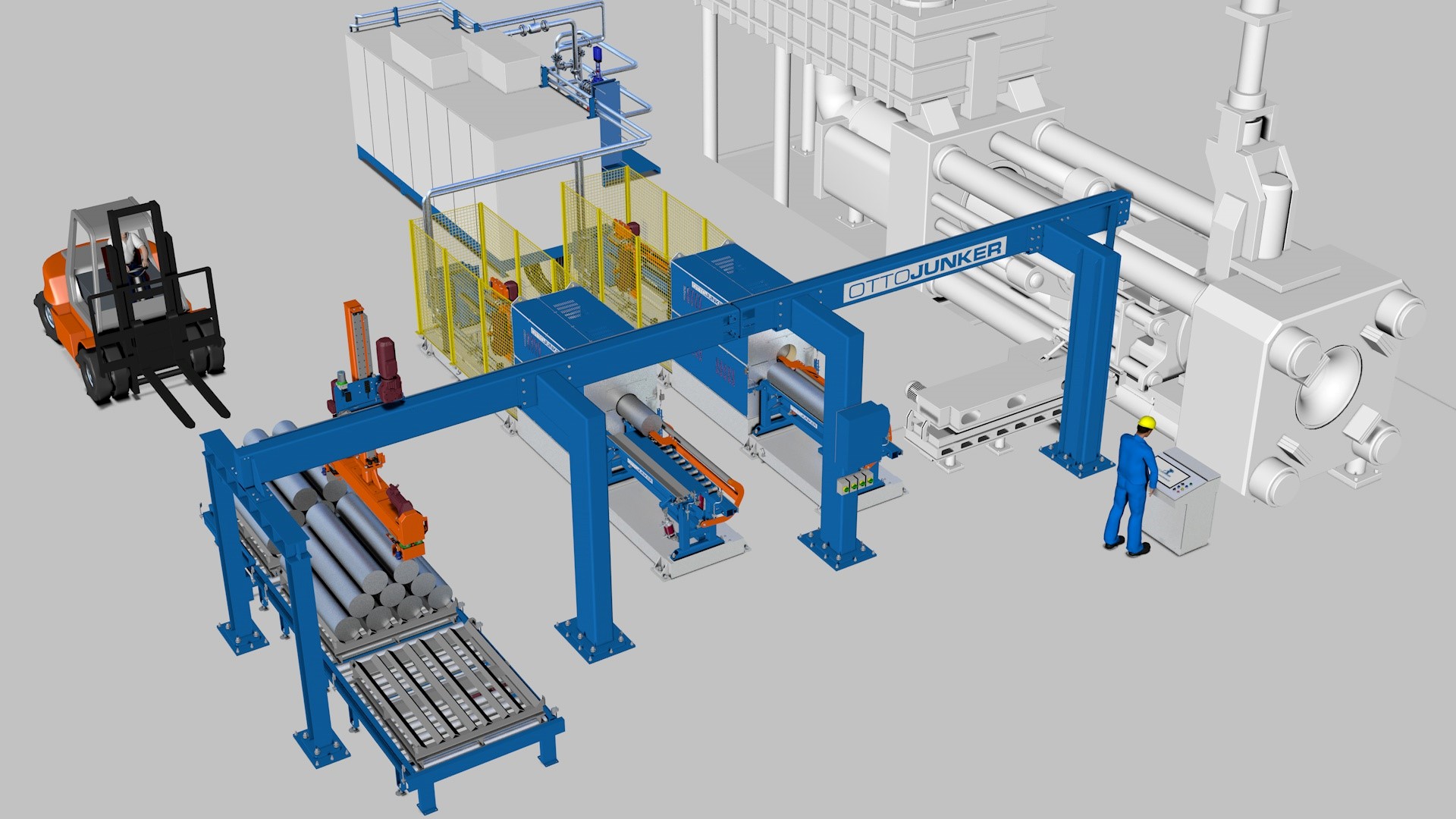

JuDy: Precise temperature control with taper

JuDy (JunkerDynamicHeater®) is an induction-heated furnace which revolutionises the final heating of billets. With an efficiency of approx. 58 per cent, and its ability to produce a precise temperature profile in the billet across individual zones, JuDy offers a highly efficient production. The use of a ceramic melting protection tube considerably reduces energy consumption. Thanks to the OTTO JUNKER trough conveyor system, marks and scratches on the billet surface are avoided. By using the mathematical "Billet Pilot" process model, the heat can be applied in an optimised manner, and the heat-up time can be reduced. Both the IGBT converter and the coils are core components produced in-house, which are extensively tested and fine-tuned before shipment.

JuDy offers the flexibility required for applications while at the same time guaranteeing a reproducible temperature profile. This solution complements electrically-heated preheating furnaces - as "stand-alone," parallel and in-line.

The best thing, however, is the combination between EcoJet and JuDy, which, together, achieve impressive efficiency.

Potential fields of application

EcoJet and Judy are not only technological milestones but also offer a wide range of options for various branches of industry. The furnaces can be used for a huge number of applications in order to improve efficiency, minimise environmental impact and lower costs.

Examples of branches where a significant additional value can be achieved:

Metal processing and foundries: In the metal industry, EcoJet and JuDy can help optimise energy consumption, speeding up production processes and improving the quality of the final product. This is of particular importance for the production of aluminium and copper.

Renewable energies: Precise heating processes are of major importance in the solar energy, wind energy and battery production fields. EcoJet and JuDy offer sustainable solutions for the production of components for these fast-growing sectors.

Automotive industry: The automotive sector can benefit from the advantages offered by these innovative furnaces through the precise heating of billets and other metal parts, making manufacturing automotive components more efficient and environmentally friendly.

Stefan Krieger, the Sales Engineer - Sales Services Foundry Plants - Billet Heating - OTTO JUNKER, said, "The introduction of EcoJet and JuDy represents an important milestone in our continuous technological evolution. With almost 100 years of experience in designing and manufacturing industrial furnaces, we have developed these products to fulfil our customers' increasing demands. Our innovative strength and the high efficiency of these furnaces result from our efforts over several decades."

Companies and experts from the industry are invited to explore the potential offered by EcoJet and JuDy to optimise their production processes. The OTTO JUNKER Sales & Service Team will be happy to be at your disposal for any further information you may require or for issuing quotations.

Responses