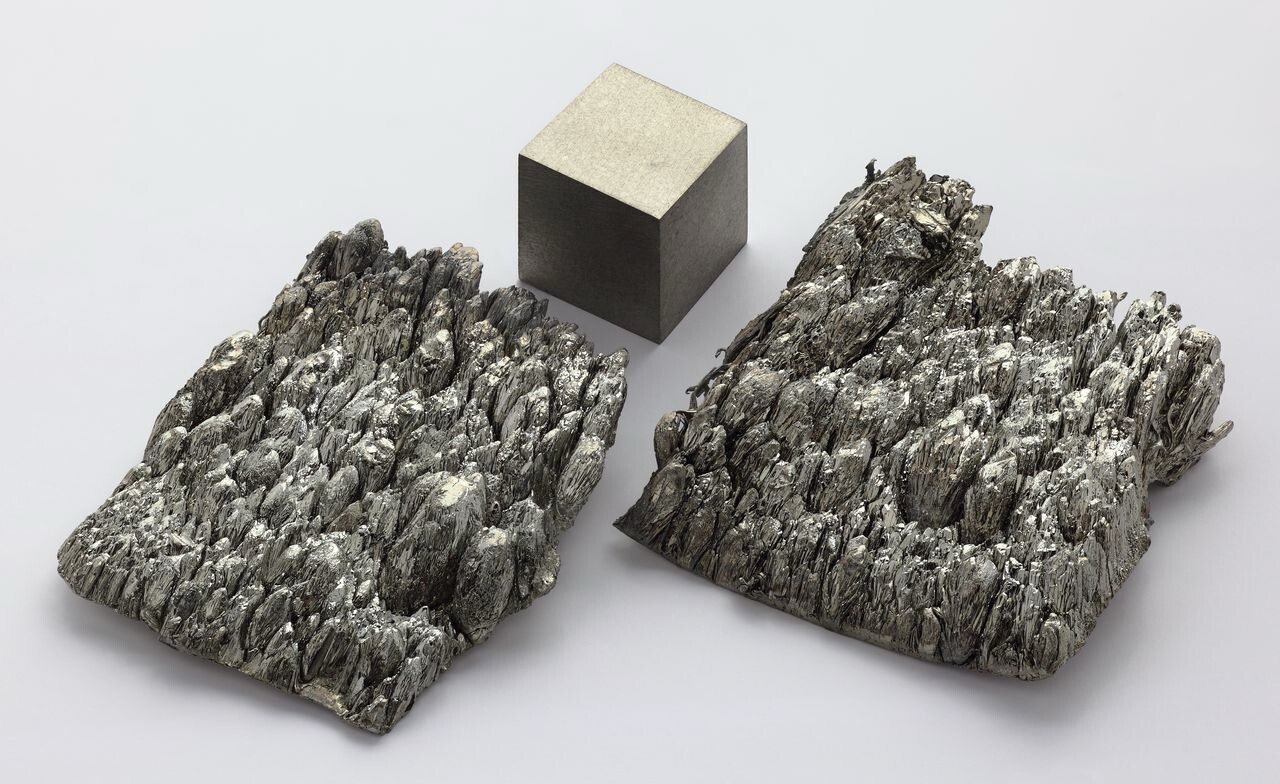

RUSAL, one of the world's largest aluminium producers, is setting up a pilot production facility for scandium oxide with an annual capacity of 1.5 tonnes. Scandium is a valuable rare earth metal, and RUSAL was the first in the world to develop and implement aluminium-scandium alloys. These alloys are used in the production of ultra-lightweight components for civil shipbuilding, railway car manufacturing, and 3D printing of high-tech prosthetics. The total global production of scandium oxide is estimated at 20-25 tonnes per year.

A pilot facility for the production of 1,550 kg of scandium oxide per year is being built at RUSAL's Bogoslovsky Aluminium Smelter (Krasnoturyinsk, Sverdlovsk Region). The facility is scheduled to be commissioned by the end of 2025. Already at its pilot stage, this project will position the company among the world's leading scandium oxide producers.

RUSAL will make scandium oxide from red mud, a by-product of alumina production at the Bogoslovsky Aluminium Smelter. The RUSAL Engineering and Technology Centre developed the technology for extracting scandium oxide from red mud, and RUSAL also designed the technology for the project. The investment in the project amounts to 500 million roubles. With the transition to commercial production, scandium oxide production volumes can increase to 19 tonnes per year.

Scandium is one of the so-called dispersed elements found in microscopic concentrations in various ores. Its extraction is a complex and often economically unfeasible process. RUSAL is the only company in the world developing a technology for obtaining scandium oxide from red mud. Globally, scandium oxide is mainly produced as a by-product of titanium dioxide or uranium production.

The primary application of scandium oxide is the production of solid oxide fuel cells for electrochemical power generators. RUSAL was the first company in the world to develop the concept of cost-effective alloying and has created unique aluminium-scandium alloys with a more than threefold reduction of costly scandium additives. Scandium enhances the strength of alloys, allowing for a reduction in the weight of the final product compared to conventional alloys. This is a significant advantage in various aluminium applications, particularly in the transportation industry, where reducing vehicle weight is a major global trend. Lightweight aluminium-scandium alloys contribute to energy efficiency, reducing CO₂ emissions and saving fuel.

Another important environmental aspect of this project is that the chemical processes used in RUSAL's scandium oxide production technology actively bind large amounts of carbon dioxide. Approximately 1.8 tonnes of CO₂ will be absorbed for every kilogram of scandium oxide produced.

Note: This press release has been issued by RUSAL and has been published by AL Circle with minor modifications and edits in sentence building.

Image credit: Rusal

Responses