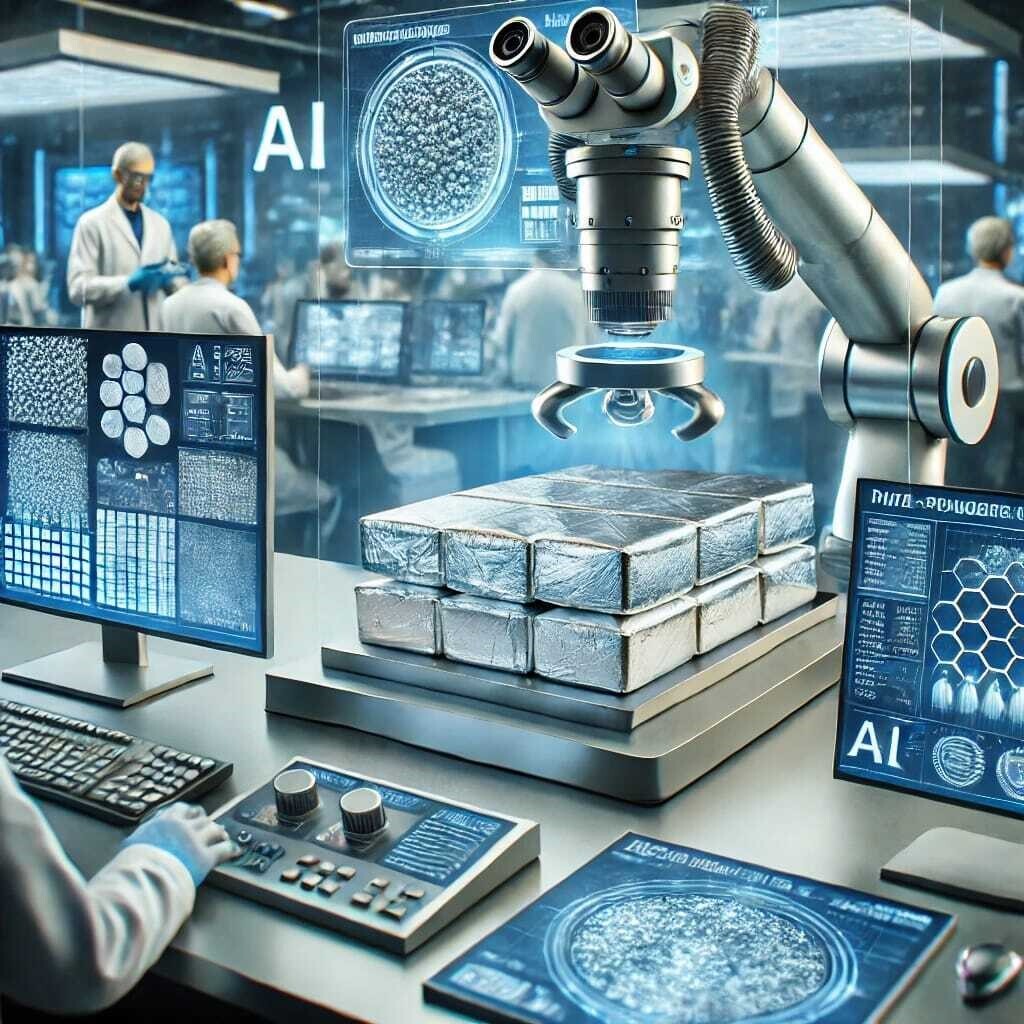

RUSAL, one of the world’s largest aluminium producers, has deployed artificial intelligence to enhance the microstructure analysis of aluminium ingots. This proprietary technology reduces analysis time from several hours to just 15 minutes, streamlining quality control and minimising repetitive manual tasks.

Developed by the RUSAL Engineering Center, this AI-driven microstructure analysis system leverages machine vision and neural networks to assess cylindrical ingots—one of the most advanced and high-demand aluminium products. These ingots are crucial in engineering, construction, and aerospace industries, where their quality directly influences final product performance and the longevity of extrusion equipment.

“The neural network assesses ingot samples across eight key microstructural parameters, including grain size and the number and size of inclusions. Traditional microscope-based analysis can take anywhere from 90 minutes to four hours, whereas our AI system delivers a comprehensive report in just 15 minutes. This demonstrates how industrial AI is revolutionizing quality control in cylindrical ingot production,” a company representative explained.

The technology is already operational at the RUSAL Engineering Center laboratory, and it will soon be rolled out to aluminium smelter laboratories for real-time quality assessment of finished products.

Mikhail Grinishin, Director of Production Automation at the RUSAL Engineering Center, said, “Each of the eight parameters has its dedicated neural network, trained on a dataset of digital microscope images annotated by scientific laboratory specialists. Our AI system delivers results with the same accuracy as a trained laboratory technician but in a fraction of the time. Moreover, its high repeatability eliminates human error, ensuring consistent quality control.”

Cylindrical ingots are a key form of aluminium alloy used in diverse applications, from construction and industrial structures to precision-engineered components in the energy sector. Their high demand underscores the importance of RUSAL’s AI-driven quality control, ensuring optimal material performance across industries.

Image credit: This is an AI-generated image

Note: This press release was issued by RUSAL and published by AL Circle without any edits.

Responses