At the recent UK Cast Metals Industry Awards, a lost wax metal casting specialist has seen its transformational prosthetic aluminium thumb for children win 'Component of the Year'.

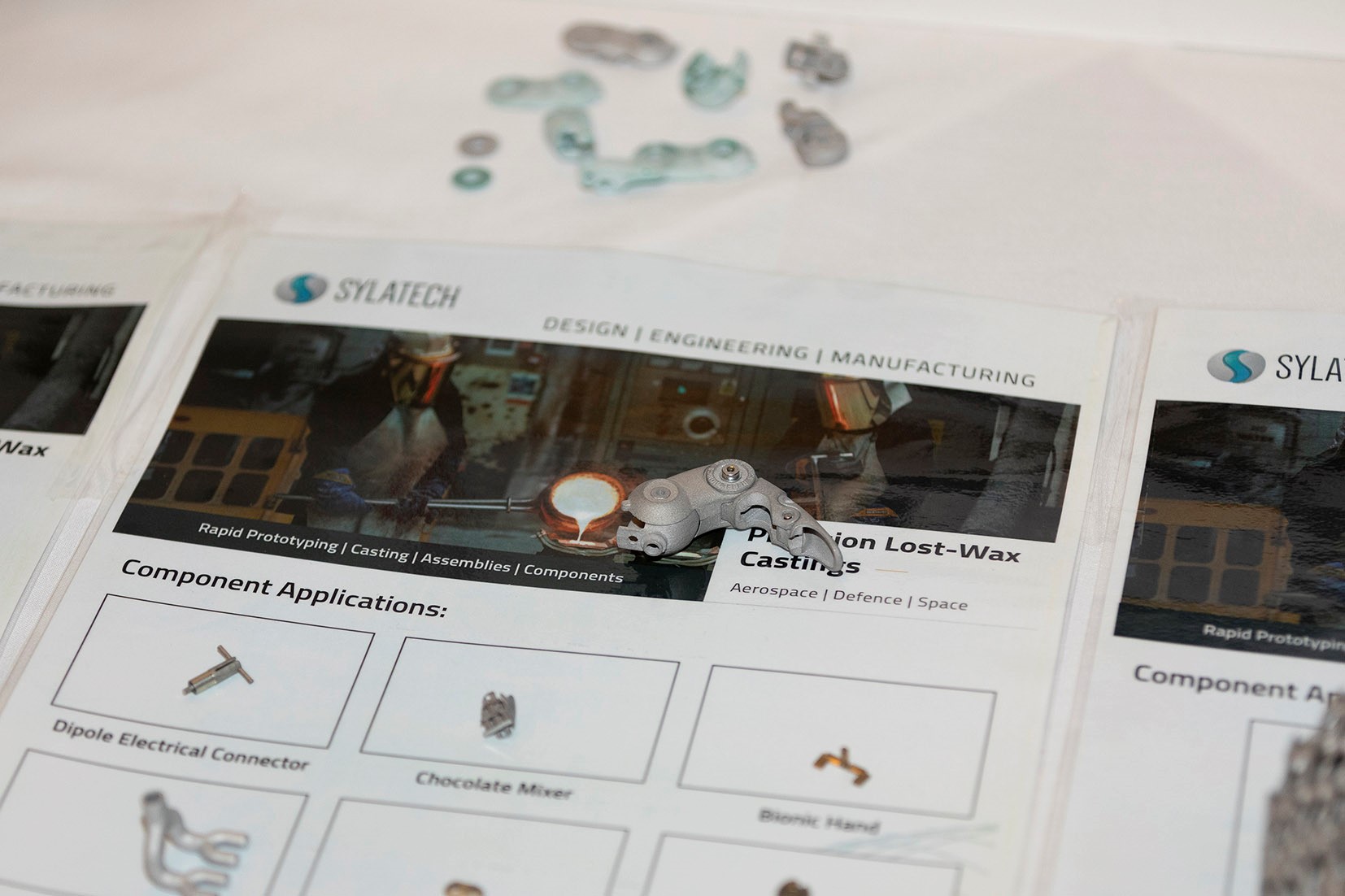

Kirkbymoorside-based Sylatech beat off the challenge of other finalists to secure the major title, impressing judges with how it has helped bring a product to market that will help young people who have lost a hand due to injury, congenital conditions or other medical reasons.

Designed by prosthetic hand designer Ted Varley, the thumb required a high level of detail and an as-cast surface finish with no machining.

With wall thicknesses down to 2mm for some cast elements and 1mm diameter cast-in holes, Sylatech used 3D wax printing to optimise the design flexibility.

Samples were provided to the client within three weeks of placing the order, with significant cost savings also achieved.

Organised by the Cast Metals Federation (CMF), there were also major accolades for Foseco (Innovation) and William Cook Holdings, who claimed the Company of the Year title.

The latter secured landmark rail contract wins, supported the war effort in Ukraine and delivered a £5m investment programme that has reinforced its position in the nuclear power supply chain.

"The innovation and resilience of the foundry industry never ceases to amaze me, and this year's award winners typify exactly what makes the UK great," explained Dr Pam Murrell, Chief Executive of the Cast Metals Federation.

"We had businesses investing, companies diversifying, and firms using new technologies to help designers bring products to market that will positively change lives for hundreds of children."

The UK Cast Metals Industry Awards, which attracted nearly 200 guests, focused on the great metal castings manufactured by UK foundries and their huge achievements in innovation, growth, and component performance.

Co-presented by Dr Pam Murrell and comedian Geoff Norcott, the evening clearly showcased the successes of the sector and its evolving impact on UK manufacturing.

This was typified by the Innovation winner, with Foseco recognised for the way it has developed a novel automated metal treatment and cleaning process for steel melts.

'ROTOCLENE' introduces inert gases through a pumping rotor, with the bubbles and stirring motion ensuring that cleaning is optimised and melt homogeneity improved, leading to lower levels of rework and scrap.

_(1)_0_0.jpg)

When combined with HOLLOTEX shrouding, lower pouring temperatures and cleaner castings with improved finer grain sizes are possible.

Pam concluded, "The commitment to problem-solving and providing solutions to customers remains within our industry, making all the components upon which a modern economy depends. Our sector can be part of the solution to growth for the UK. And remember – metal recycles forever."

Responses