The Learning Aluminium Plant A step towards a new industrial revolution: SMS digital GmbH

Maximum plant efficiency through digitalization

SMS group has elevated digital transformation to an entrepreneurial strategy as changing market conditions determine whether a company can be still successful in the future or not. Since then, the management structure, corporate divisions, the product range, and corporate culture have been under review for adapting to the new circumstances. This is where SMS digital was born: A company with a special background as SMS digital combines best of both worlds – 150 years of experience in metallurgical plant engineering and up-to-date technology and expertise in digitalization.

{alcircleadd}As the digital subsidiary of SMS group, SMS digital develops innovative solutions with which it “digitalizes” the metal industry to go straight towards its vision of the Learning Aluminum Plant. The main task of the learning aluminum plant is to turn data into value. It takes full advantage of innovative technologies to increase its productivity and user friendliness and has a hugely positive impact on sustainable “green” aluminum production. Being a part of a globally operating group, SMS digital has access to specialized domain knowledge around the globe with regard to any production route in the aluminum industry. Although a young company, SMS digital also profits from a broad variety of digitalization products and services, which ideally meet their customer’s needs. The services of SMS digital include digital solutions and consulting services with regard to operational expertise, platform services, digital products and apps, customized development solutions as well as data analysis and machine learning services.

SMS digital’s vision of the Learning Aluminum Plant

The Learning Aluminum Plant auto-adaptively optimizes its production process as part of an integrated value chain, based on physical plant elements, data driven models and systems with regard to production planning, product quality, and plant condition.

The term “Learning Aluminum Plant” is scalable and shows the different facets of digitalization. Learning can start with a typical reflection on the activities performed and adopting to changes in the environment, providing long-life education to build-up capabilities and know-how. At the same time, learning can be pushed to a higher level by utilizing artificial intelligence to allow systems to optimize themselves or even allow systems to auto-adaptively learn by themselves.

Although SMS group’s largest share of the business is within the steel industry, digital technologies can be and are of course, utilized in many other industries. There are industries naturally very close to steel, for example, aluminum or copper , but the digital technologies and methods developed by SMS group are so generic that they are even applicable in the paper- or glass industry.

The word “Plant” is scalable in terms of project scopes. Digital solutions can be provided for single parts by, for example, providing an innovative spare parts order platform, for a certain machine type by providing first class automation systems, for a whole plant complex allowing efficient production planning, quality or logistics processes, up to solutions for several locations by providing business intelligence solutions to allow enterprise-wide transparency in order to meet the enterprise key performance indicator.

Fig 1: The Learning Aluminum Plant

Central industry-specific platform solution mySMS

In the first step, we add value to data. But this is not where the journey ends. To make now visible use of the data, SMS digital developed the mySMS platform. With this industry-specific Software-as-a-Service (SaaS) platform for the metals industry, SMS digital is hosting and connecting the most relevant applications for the fast and direct digitalization of business. Accordingly, customers can connect to the Industrial Internet of Things (IIoT) platform and use its apps. This results in many advantages. It also works as a central element of communication between SMS digital and the customer. The implementation of SaaS solutions is uncomplicated, fast and cost-effective and users benefit from a single-sign-on for all applications in one interface.

Fig. 2: mySMSgroup platform

Key solutions of SMS digital

All products that SMS digital offers can be categorized into three different, but connected product ranges: Planning, Quality, and Condition. Planning refers to all our products and services that serve the aim of optimizing the production planning and scheduling. One of the key products SMS digital can offer is the production planning system X-Pact MES 4.0. It provides a complete set of expandable functions available from just one supplier. The whole process from the reception of the customer order until the shipment can be tracked. The system integrates harmoniously into an existing IT landscape.

Fig. 3: Manufacturing Execution system X-Pact MES 4.0

(Product) Quality provides services to monitor, document, analyze and secure the product quality up to automated grading processes and to optimize by the use of artificial intelligence e.g. by automatic root cause analysis. It refers to products and solutions that aim to assist the evaluation and prediction of product quality and gives insights into the root causes for quality downgrading and genealogy. One of the key products SMS digital can offer is the PQA®- The PQA® avoids processing of substandard semi-products to the next process step or finished product to the final customer.

The third product category refers to solutions dealing with maintenance and plant conditions. These products and solutions focus on aspects like plant availability, inventory management or maintenance. To all these issues SMS digital can provide a broad variety of solutions. IMMS is a product specially developed for maintenance management in an aluminum industry context.

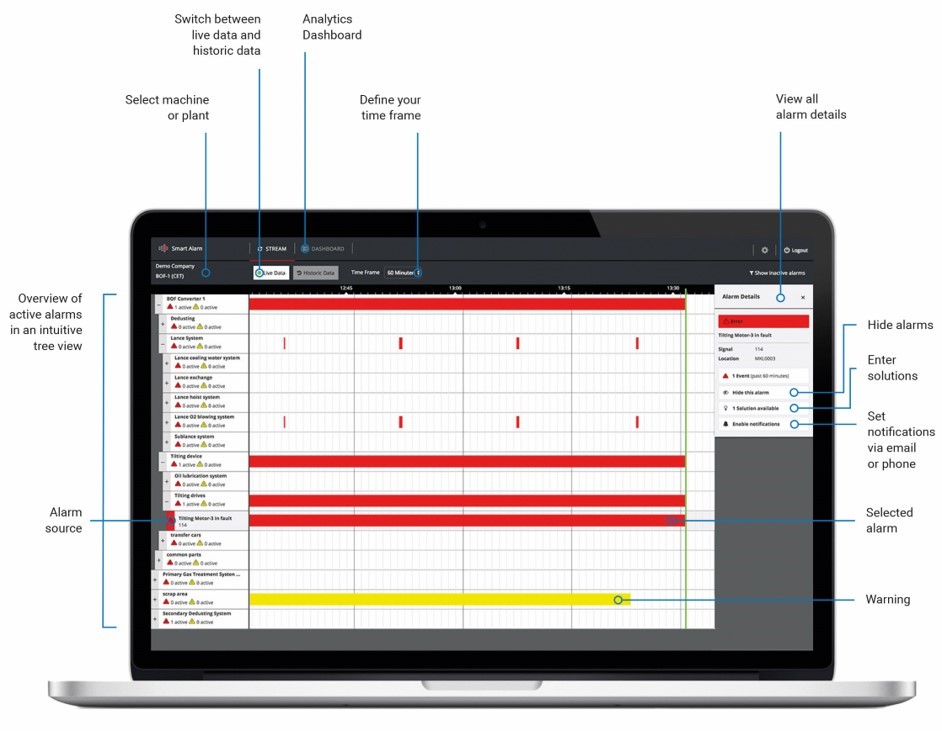

Genius CM and PCA target on condition monitoring and the Smart Alarm are an in-house developed system aiming to harmonize and depict all alarm notifications along the entire value chain of the plant.

Fig 4: Smart Alarm visualized all relevant alarms in one dashboard

Digitalization is not a hype, but a part of the ecosystem of efficient work. The implementation of digital frameworks has a direct influence on profit & loss, resulting in a sustainable competitive advantage.

This news is also available on our App 'AlCircle News' Android | iOS