Meltio, the leading manufacturer of wire-laser metal deposition systems, leaps forward and presents a new generation of metal 3D printers conceived to introduce metal additive manufacturing to the world of industrial production outside of niche areas. The new Meltio M600 is designed to solve problems of long lead times, costly stock-keeping, and increasingly fragile supply chains, thanks to its unique metal 3D printing technology. This new system increases productivity, reduces manufacturing costs, brings new materials to the table, and is, most importantly, ready to perform 24/7 with minimal operator interaction for autonomous production.

Lukas Hoppe, Research+Development Director at Meltio, said, “The design brief for the new Meltio M600 was to imagine the perfect 3D printer for the machine shop. The vast majority of metal 3D printed parts require post-processing, which is carried out in the machine shop. Since our ambition is to push the large-scale adoption of metal additive manufacturing, we have a clear vision that the modern machine shop is the ideal entry point. Manufacturing faces many challenges globally, from long lead times and stock-keeping costs caused by prolonged and fragile supply chains to an ever-growing pressure to lower costs and reduce emissions."

"3D Printing has huge potential to address these issues. It helps reduce lead times and manufacturing dependencies by printing parts in-house, reduces warehouse inventory as the raw material can be transformed into the final part on demand, and reduces costs by applying material only where it is needed."

"However, it has yet to realise this potential. In fact, we still see metal AM mostly applied to very high-value applications. This is where the Meltio M600 comes in, as it improves on the state-of-the-art in a few very significant ways:

1. Compared to the much more common powder-based 3D printer, it uses welding wire as its feedstock. Having a wire material that is much cheaper, safe to handle, and does not risk contamination of your CNC Machines is a huge advantage for industrial integration.

2. Printing Parts with our Wire-Laser Deposition process produces high-quality components with material properties comparable to conventionally manufactured parts.

3. Our newly developed Blue Laser deposition head increases printing speed while reducing energy consumption thanks to the increased absorption of the short wavelength light compared to most industrial lasers, which emit near-infrared light. This advantage is multiplied for reflective materials such as copper and aluminium alloys, where near-infrared lasers lead to unsatisfactory results. Combining this with the entirely inert workspace, the Meltio M600 can efficiently process an extensive range of materials while producing parts with exceptional properties.

4. The complete system has been designed to easily interface in the same industrial environment with CNC machines; it features a built-in 3-axis touch probe and supports various types of work-holding solutions, which means you can also add features to or repair existing parts rather than printing them entirely.

5. Lastly, the Meltio M600 is highly autonomous, meaning that operator interaction is minimal, common touch points such as manual laser alignment have been removed for increased reliability, and programming is a matter of minutes thanks to the Meltio Horizon, the dedicated slicer for the Meltio M600.

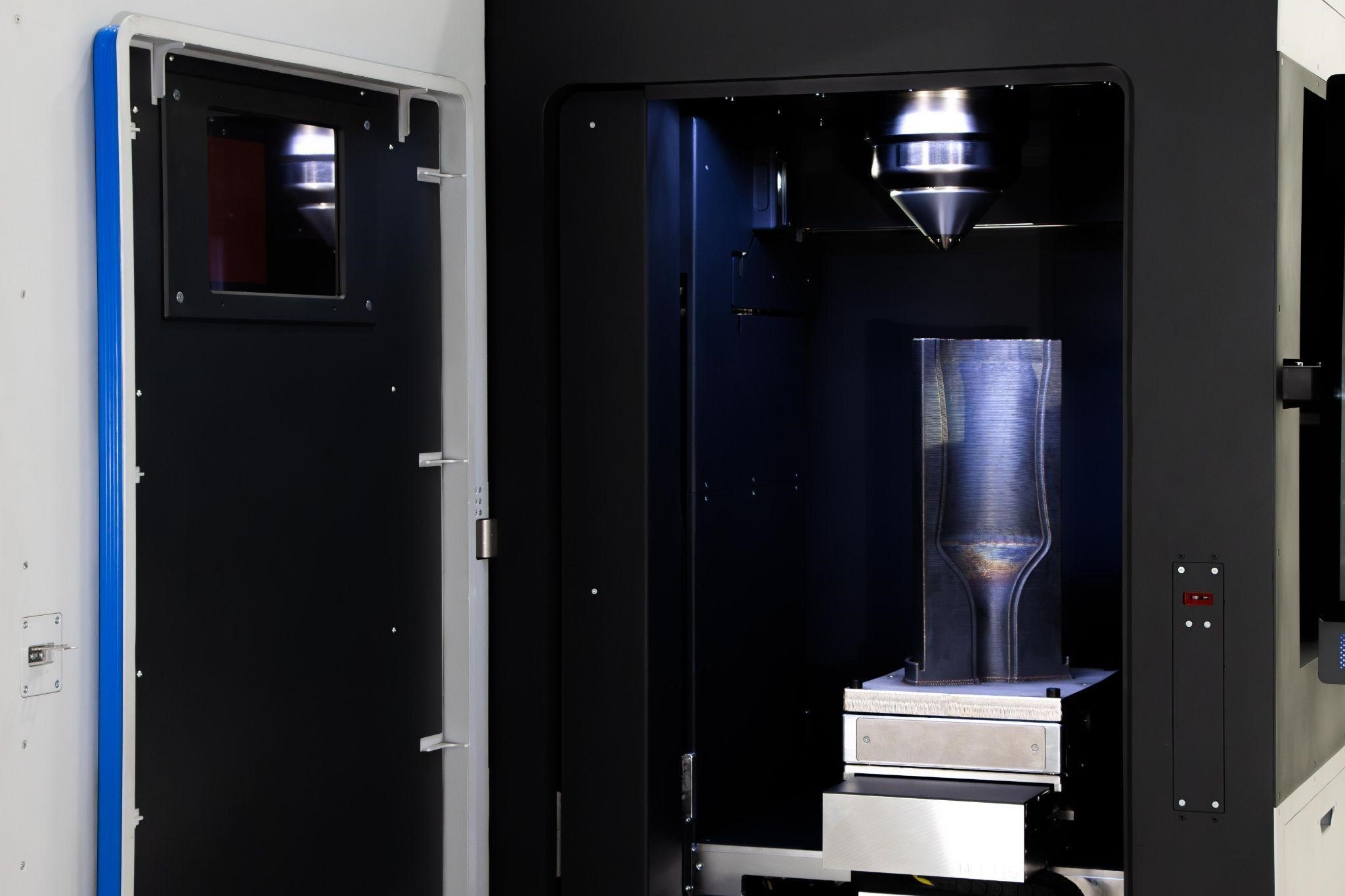

To make this new tool for machine shop use a reality, the Meltio M600 is the first Industrial wire-laser metal 3D printer that incorporates, among other technological advances, a Blue Laser deposition head. These lasers improve energy absorption and printing efficiency across the metal spectrum and open up new material possibilities while reducing the carbon footprint for production.

The Meltio engineers have also improved the energy distribution and wire guidance so that the deposition head is aligned from the factory and not operator-adjustable, leading to consistent output and vastly reduced maintenance. Lastly, the head is laden with new and improved sensor solutions for monitoring the printing process, which makes printing more reliable.

Applications

While the Meltio M600 is interesting to a broad range of sectors, the company’s goal was to design a system that fits right into any machine shop and works alongside CNC machines. This system would create value by reducing material waste and lead times, allowing for increased manufacturing flexibility. To realise this vision, we focused on a system that works like a machine tool, is designed for lights-out manufacturing, and is easy to use, enabling existing operators to complete complex print jobs with minimal time investment.

These attributes make the Meltio M600 an exciting proposition for the manufacturing industry as a whole and attract traction from a wide range of sectors, including automotive, aerospace, oil and gas, mining, and defence.

Lukas Hoppe continued, "The Meltio M600 for us was really the next logical step on our continuous journey towards mass adoption of Wire-Laser DED, the process all Meltio systems are based on. We began this work in earnest in 2019 when we started to leave the prototyping space with the launch of the Meltio M450. After learning from and improving the technology for three years, the time was finally ripe for us to work on the next system. Our goal with the Meltio M600 was to strike the right balance between machine size, cost, and productivity while being uncompromising on quality, reliability, and ease of use. To achieve this, we did not just create a 'scaled-up' M450. Instead, we developed every single part of the machine from scratch to take the technology to the next level, based on the learnings of having manufactured and installed over 300 Laser DED machines."

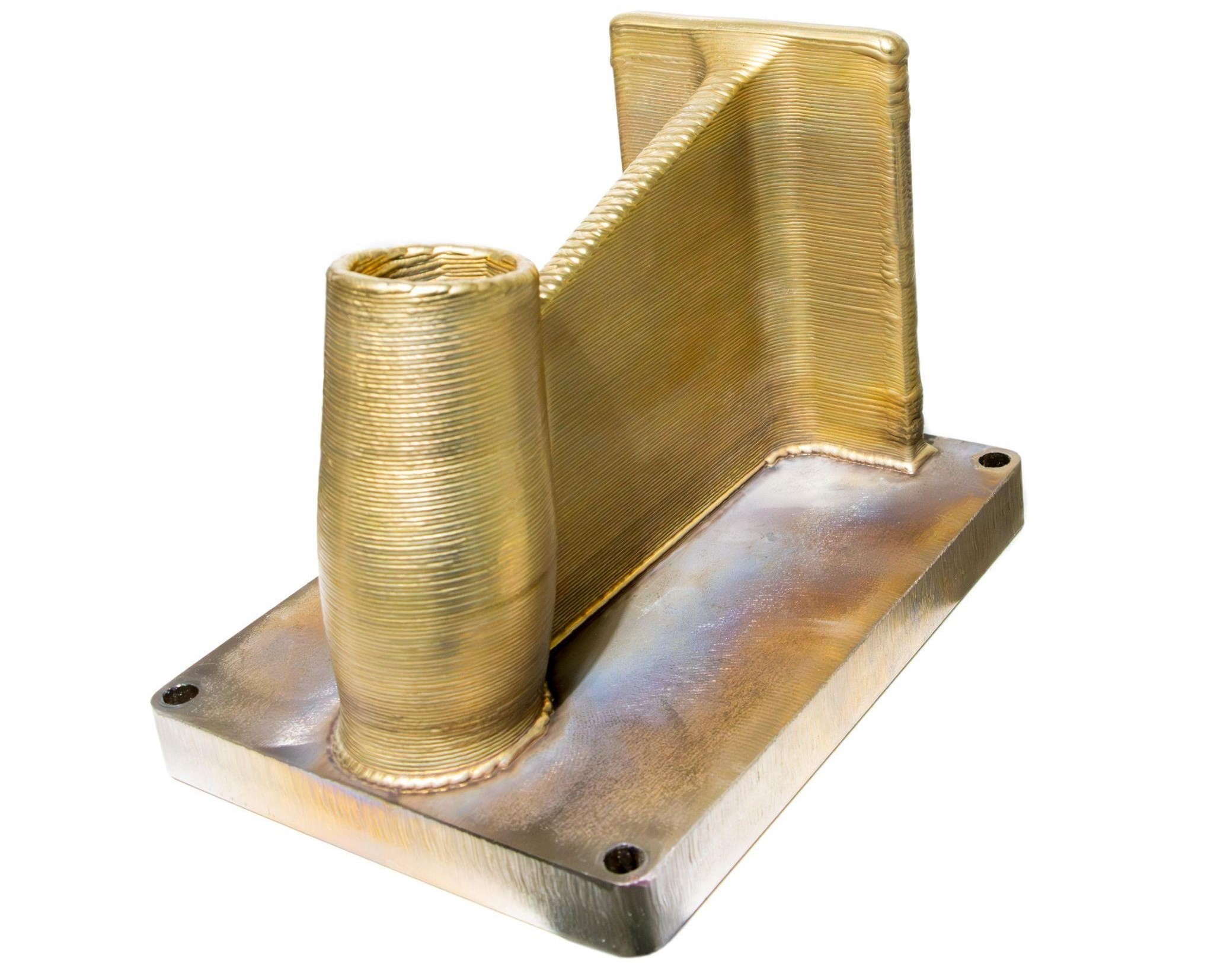

Cementos La Cruz, the real success story with the Meltio M600

Cementos La Cruz is a Spanish cement company that is increasing its productivity and efficiency by adopting Meltio's technology to manufacture metal parts. In its case, the company has manufactured with the Meltio M600 a new stainless steel nozzle that allows for manufacturing more sustainable cement parts. This company focuses on developing low-carbon footprint cementitious materials to achieve sustainable construction. Their commitment to innovation is focused on using a circular economy and developing technologies such as additive manufacturing of concrete. At their 3DLAB, they develop 3D printing solutions for construction.

The additive manufacturing process requires a high level of material flow control. The nozzle plays a decisive role in the quality of the layers, and this requires a design that can only be produced by additive manufacturing. This is why we turned to unique wire-laser metal 3D printing solutions developed by Meltio, which used a nozzle to optimize the quality of the layers and their deposition.

With Meltio's technology, they can design parts that traditional manufacturing methods couldn't produce. Thanks to the use of the nozzle printed on the Meltio M600, they have achieved the main advantage of additive manufacturing in the cement sector: the controlled deposition of the material,, producing a concrete part as it has been designed. They gain in construction control and digitalisation.

Responses